Three-dimensional laser alignment positioner for particle image velocimetry

A three-dimensional laser, particle image technology, applied in the direction of velocity/acceleration/shock meter details, instruments, measuring devices, etc., can solve the problems of human error, time-consuming, cumbersome measurement results, avoid human error, and simplify the calibration process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited by this.

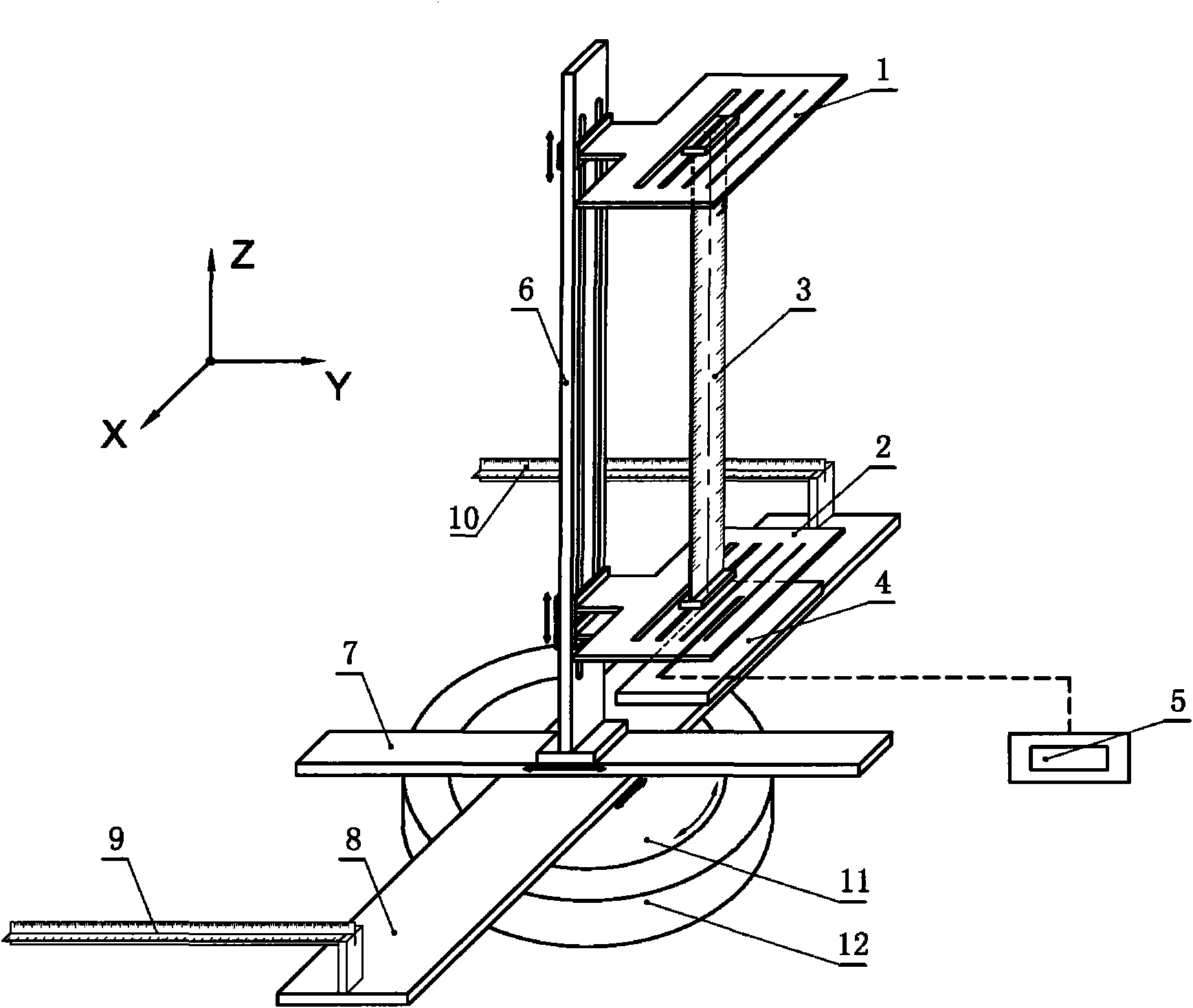

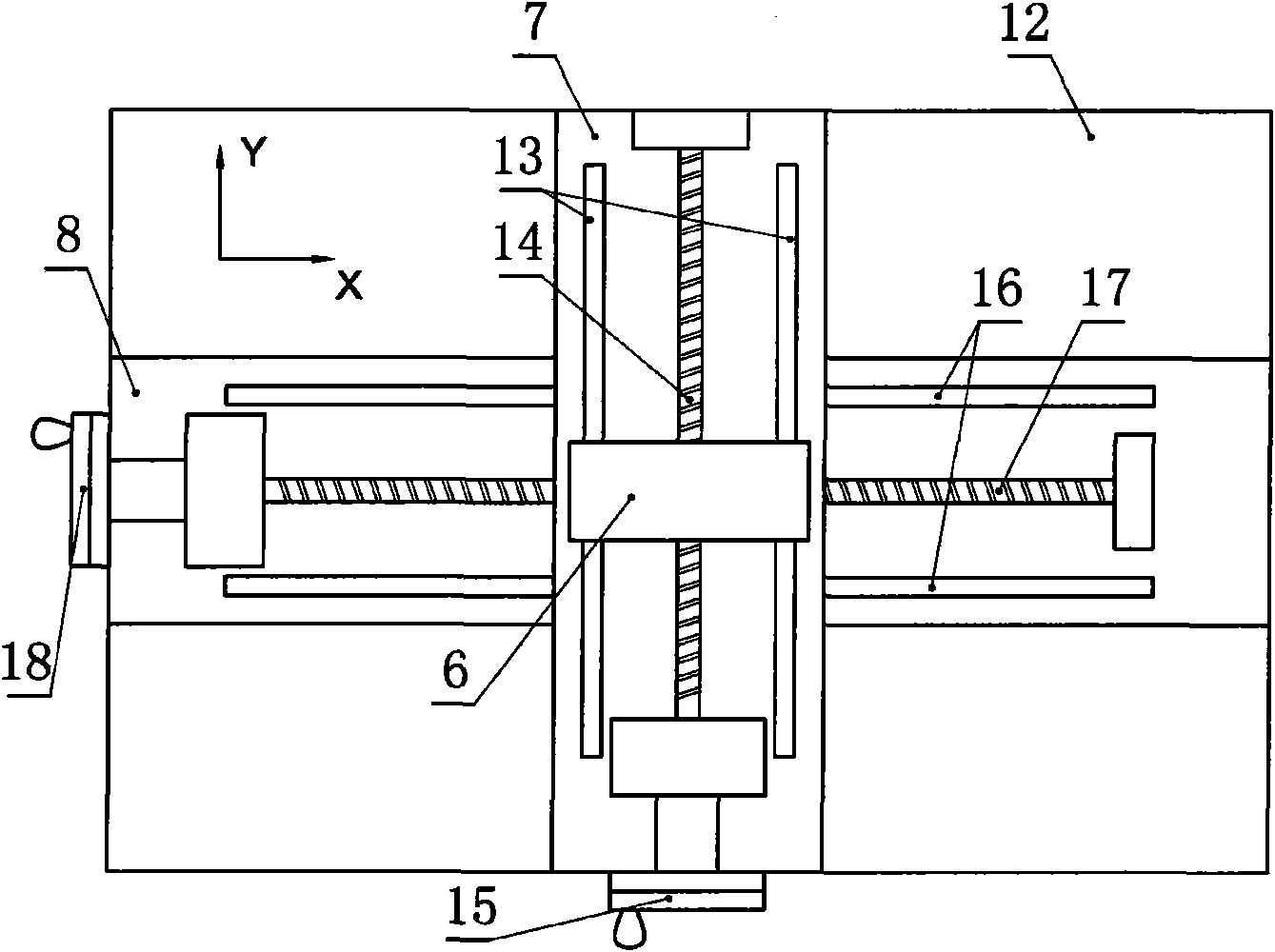

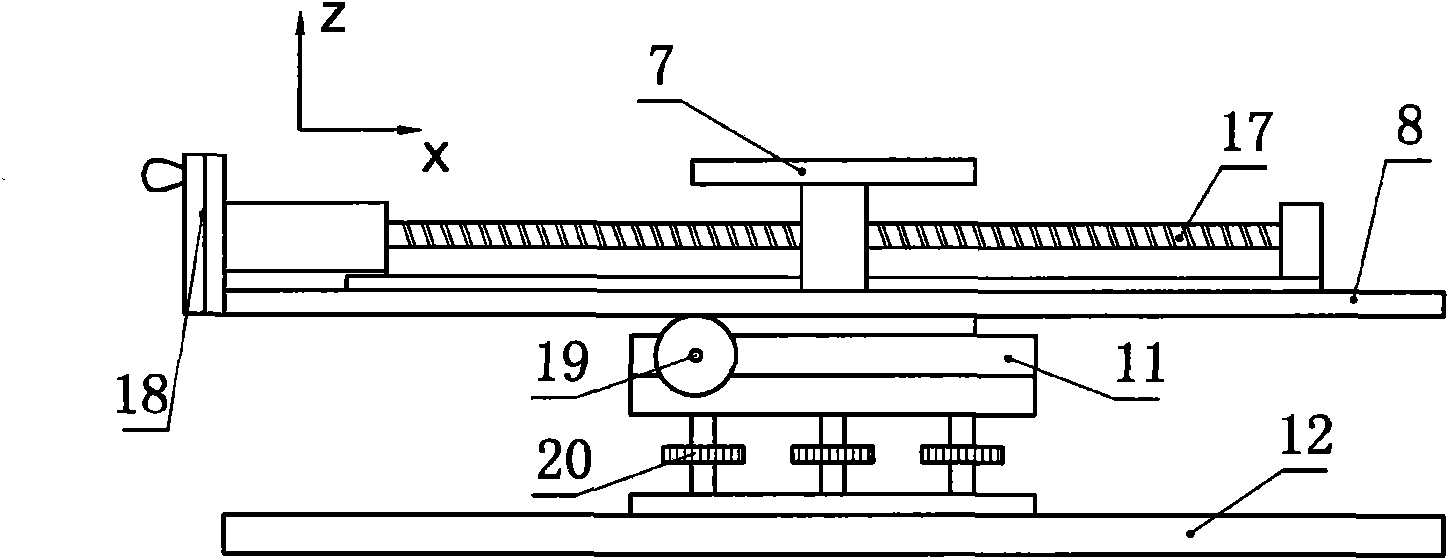

[0015] figure 1 It is a structural schematic diagram of a three-dimensional laser alignment and positioning instrument used for particle image velocimeters provided by the present invention. The positioning instrument includes a three-dimensional coordinate adjustment frame and a laser sheet light correction system; the three-dimensional coordinate adjustment frame includes Z-direction coordinates frame 6, Y coordinate frame 7, X coordinate frame 8, front positioning cross scale 9, rear positioning cross scale 10, rotating base 11 and base 12; Laser sheet light correction plate, focusing scale 3, photoelectric detection plate 4 and photoelectric indicator 5; a group of slits with different widths are arranged in parallel on the laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com