Fully-automatic diamond polishing machine

A fully automatic, stone grinding technology, applied in the direction of grinding/polishing equipment, grinding machines, machine tools suitable for grinding the edge of workpieces, etc., can solve the problem of inability to realize fully automatic production of diamond grinding and polishing machines, reduced processing efficiency, and process time Extension and other issues, to save the time of fixture transmission, improve work efficiency, and save structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

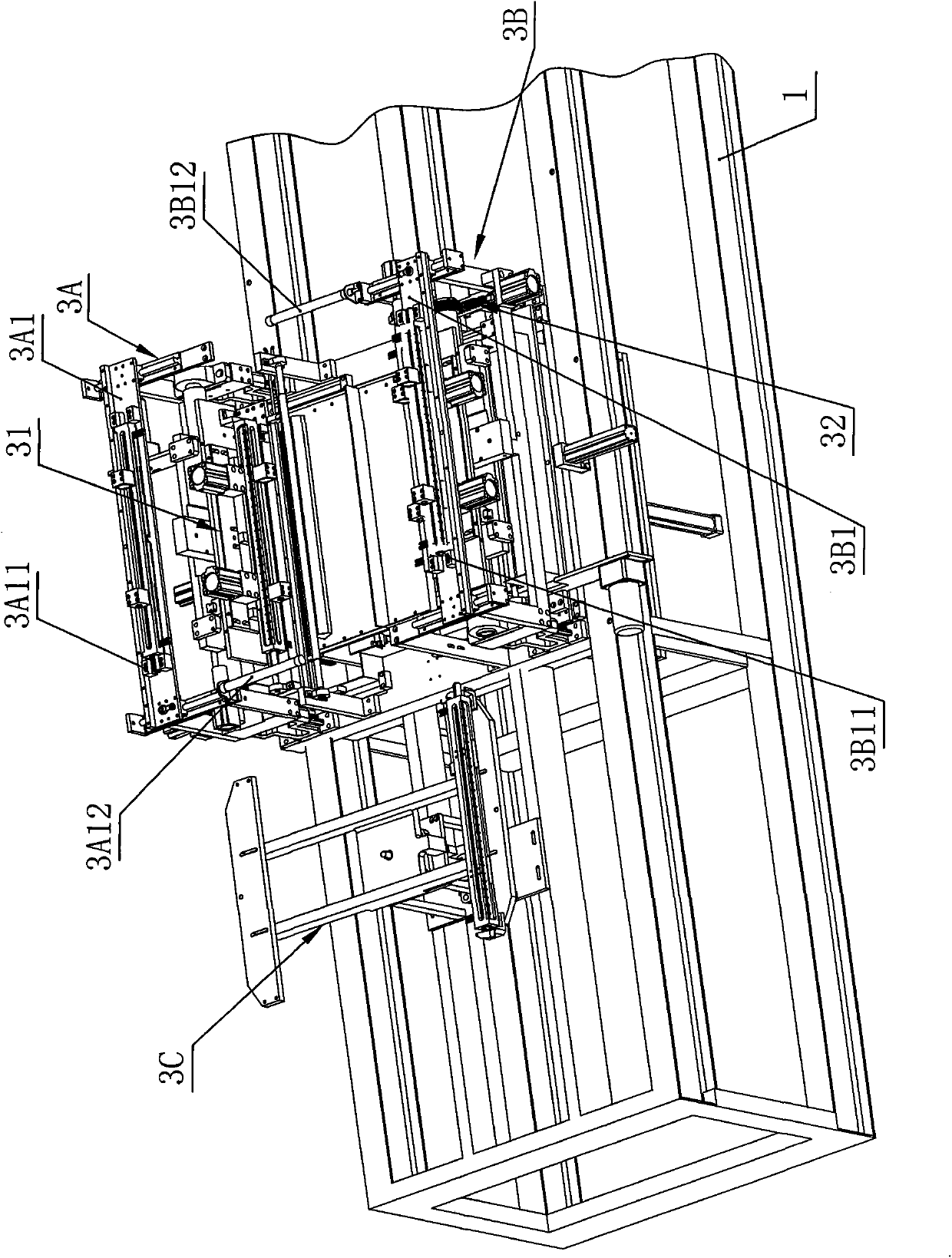

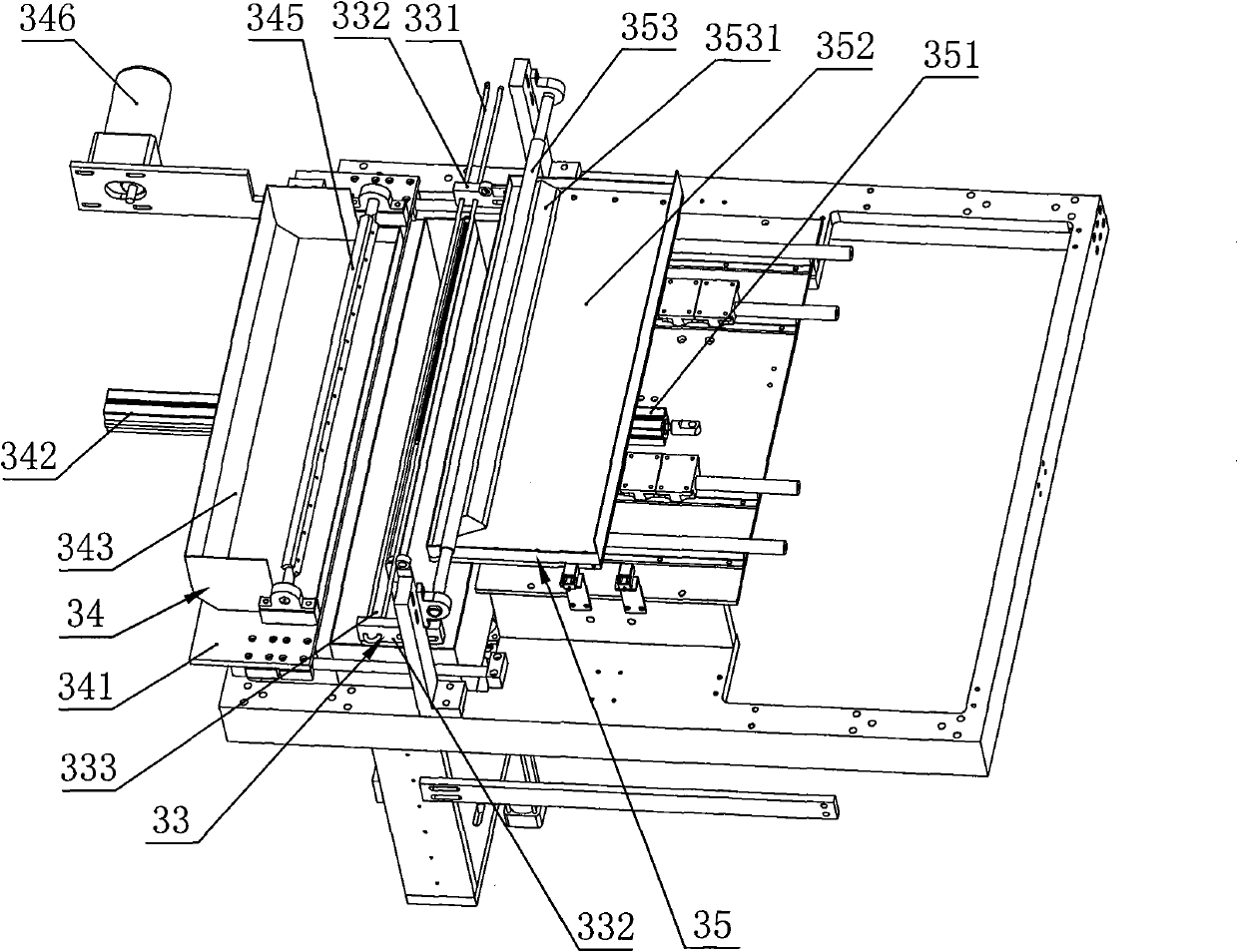

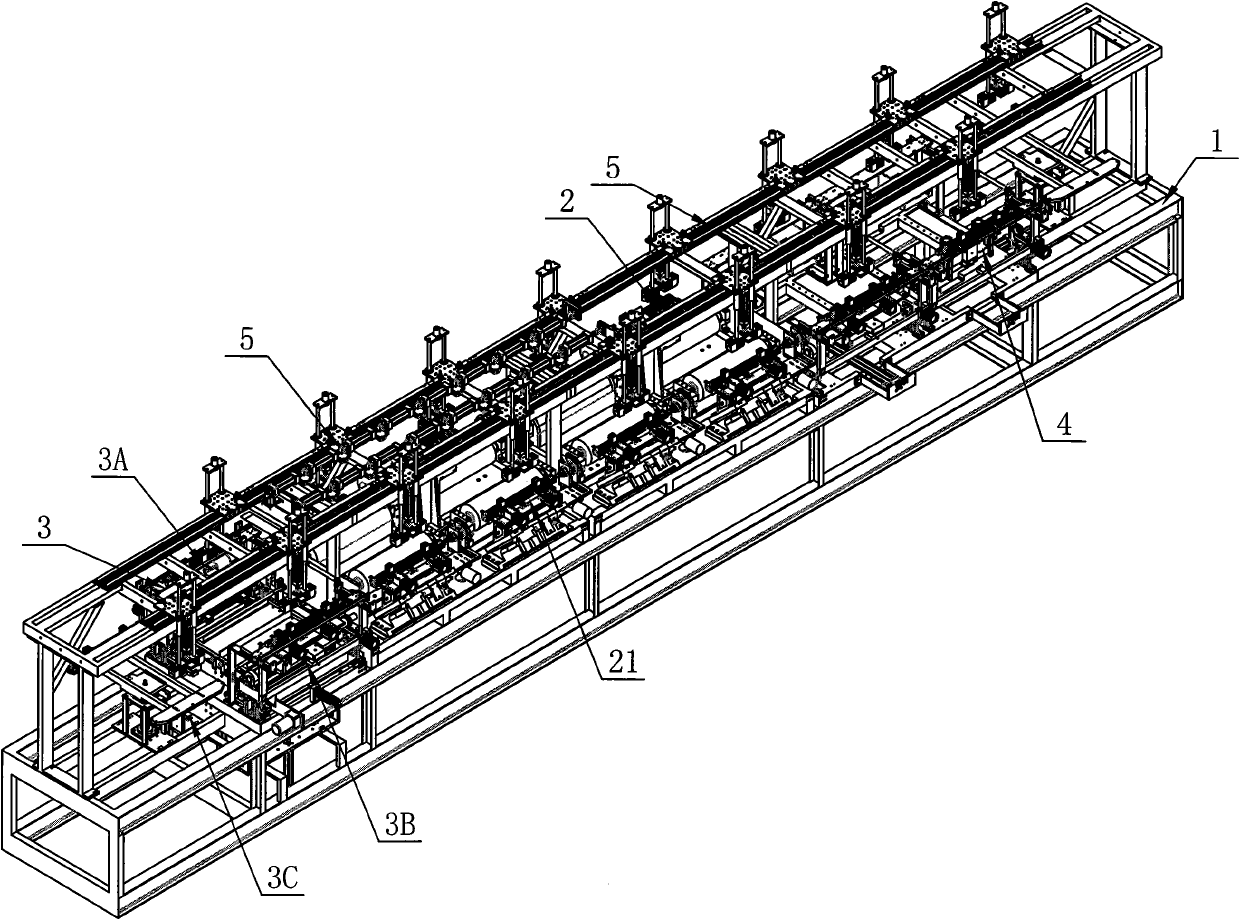

[0029] like Figure 1-16 As shown, a full-automatic diamond grinding and polishing machine includes a frame 1, two groups of grinding and polishing production lines 2 are oppositely arranged on the frame 1, and lowering, loading and fixtures are arranged on the same side of the two groups of grinding and polishing production lines 2 The conversion unit 3, on the other side of the two groups of grinding and polishing production lines 2, is provided with a transfer and fixture conversion unit 4, which is connected with the lower, loading and clamp conversion unit 3, two sets of grinding and polishing production lines 2 and the transfer and fixture conversion unit 4 Corresponding clamp transfer mechanism 5, described bottom, loading and clamp conversion unit 3 includes two groups of lower and upper feeding devices 3A, 3B symmetrically arranged on the frame 1, arranged on two groups of lower and upper feeding devices 3A, 3B, 3B, the clamp conversion device 3C on the same side, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com