Method for producing rubber bottle cork for medicament bottle and rubber bottle cork produced by employing same

A production method and technology of plastic bottle stoppers, applied in the field of plastic bottle stoppers, can solve the problems of low production efficiency and large investment in equipment, and achieve the effects of high-efficiency manufacturing, less pollution of drugs, and fast connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

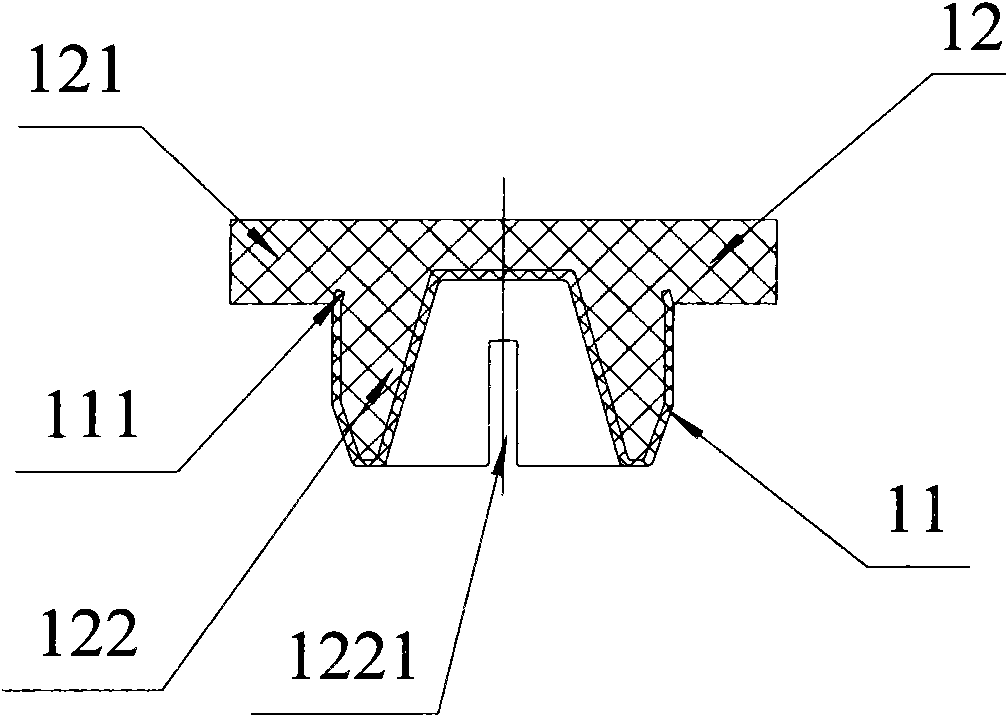

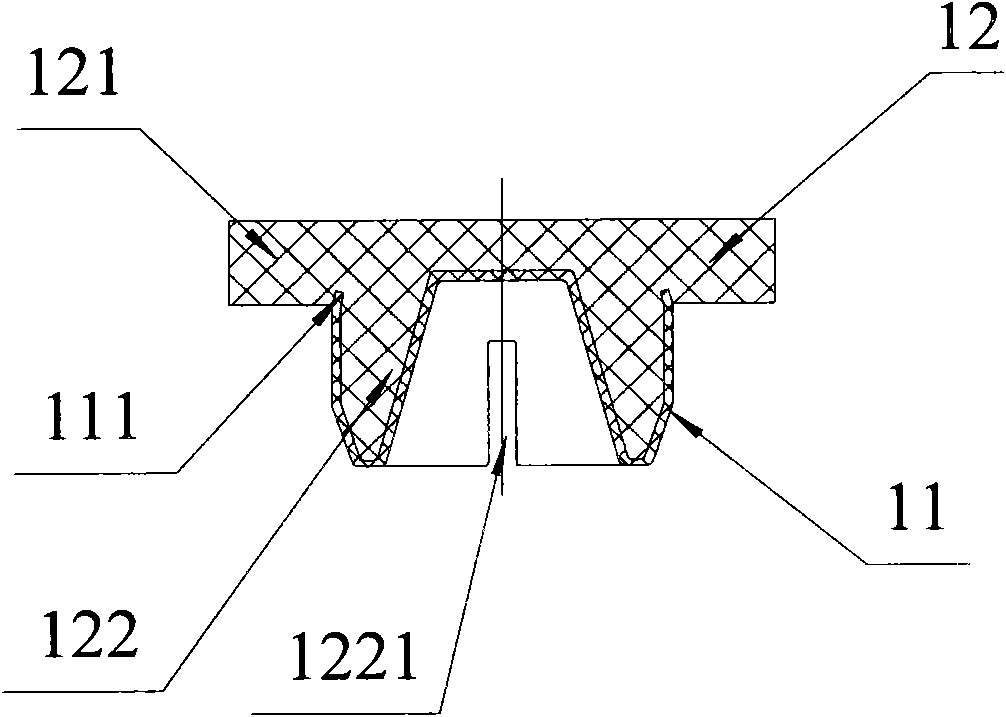

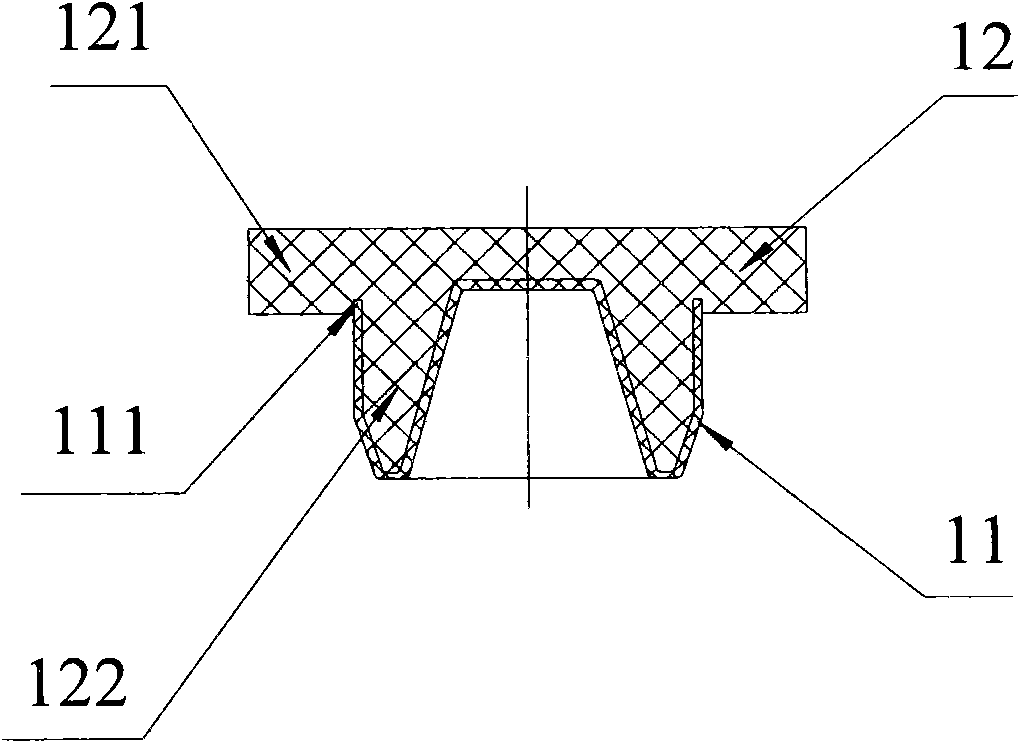

[0020] A feature of the present invention is that the inner plug is formed by molding, and then the inner plug and the rubber material used to form the outer plug are placed in a mold for vulcanization to form the final composite rubber plug. During the vulcanization process, the inner plug and the outer plug are tightly combined into one. And the molding method is very simple.

[0021] The molding method used in the present invention is injection molding.

[0022] Preferably, after the inner plug is formed, the surface of the inner plug is subjected to physical or chemical treatment to remove dirt on the surface and / or activate the surface so that the surface can easily interact with the rubber material.

[0023] The materials used to form the inner plug are known in the prior art, such as the aforementioned film-forming materials that do not easily interact with drugs. The temperature and time of vulcanization should be selected according to the characteristics of rubber a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap