Double-clutch automatic transmission without reverse gear shaft

An automatic transmission and dual clutch technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of increasing gears, complex structure, increasing the overall weight of the transmission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

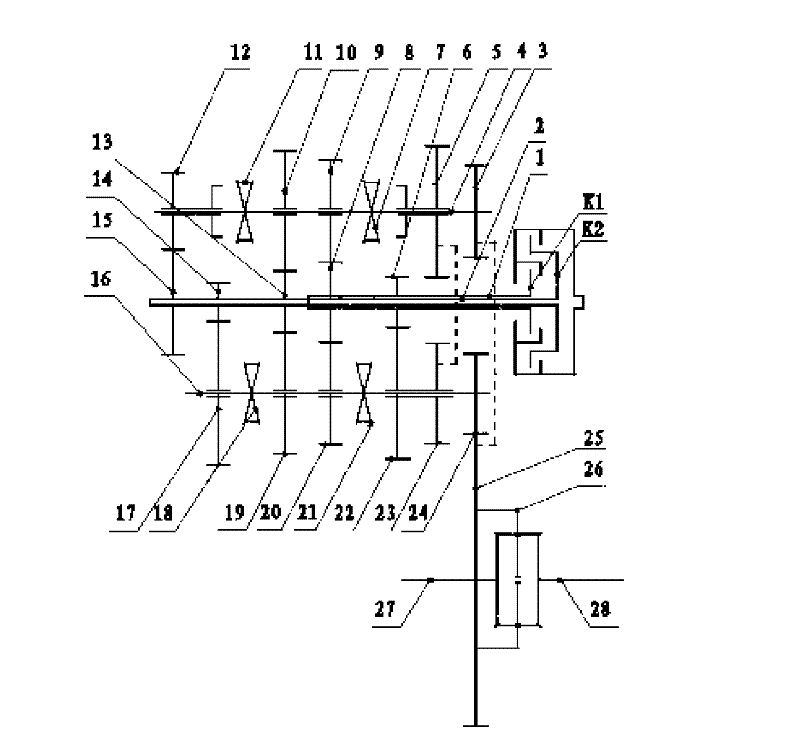

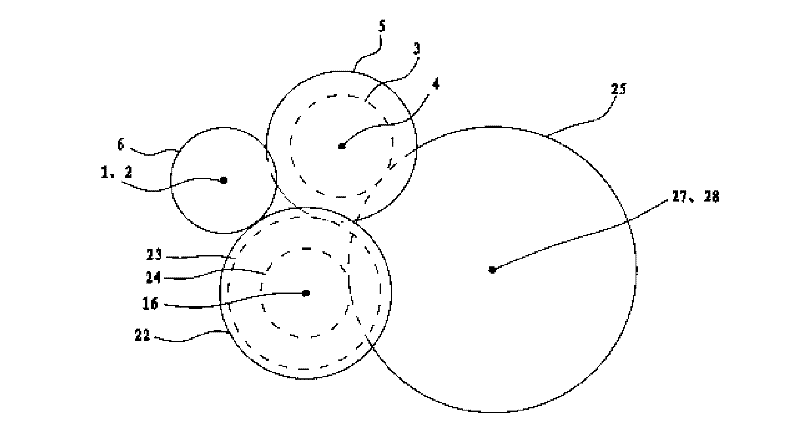

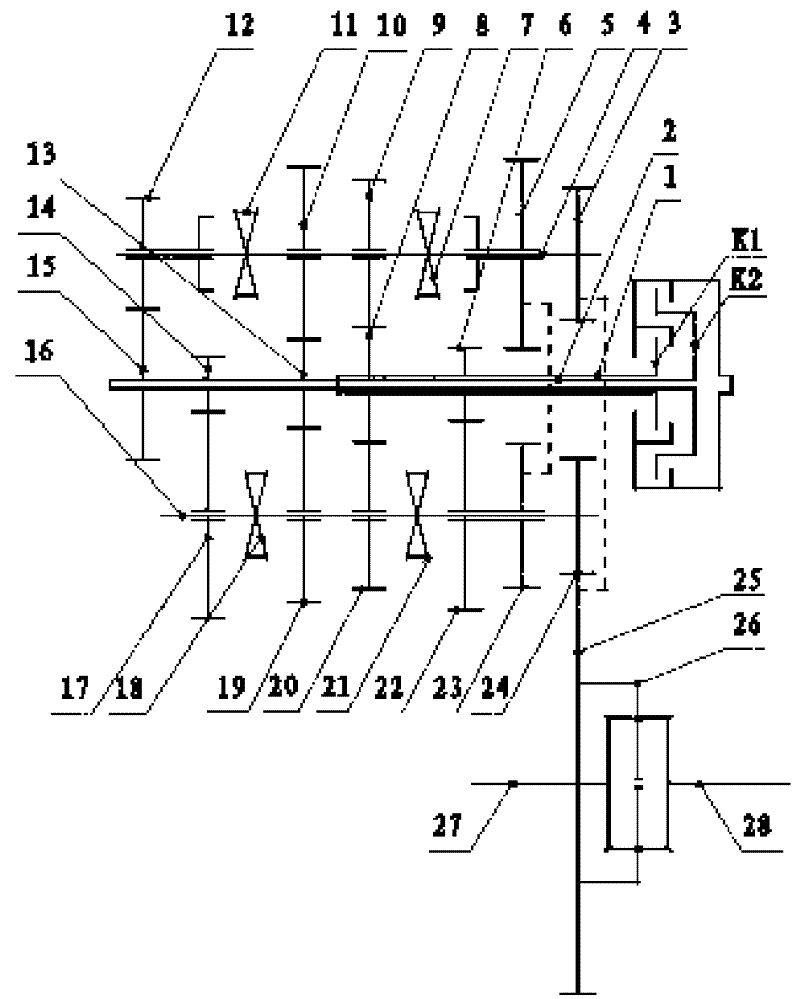

[0049] The technical solutions of the present invention are further described in detail in the following embodiments given in conjunction with the accompanying drawings.

[0050] See attached figure 1 , figure 2 , a double-clutch automatic transmission without a reverse shaft, comprising a clutch one K1, a clutch two K2, an input shaft 1, an input shaft 2, an output shaft 16, an output shaft 4 and a differential; the input shaft 1 Shaft 1 is coaxial with the second input shaft 2 and rotates around it; the first clutch K1 and the second clutch K2 are connected to the first input shaft 1 and the second input shaft 2 respectively, and alternately transmit working power to realize gear switching , the differential includes a final reduction driven gear 25 , a side gear 27 and a side gear 28 .

[0051] On the input shaft 1, the second gear driving gear 6 and the fourth and sixth gear driving gears 8 are arranged in sequence.

[0052] Three or five gears driving gear 13, first gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com