Enclosed air system of medium speed mill in heat-engine plant

A technology of sealing air and coal mills, which is applied in combustion methods, block/powder fuel preparation, grain processing, etc., and can solve the problems of energy waste, safety and reliability of the sealing air system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

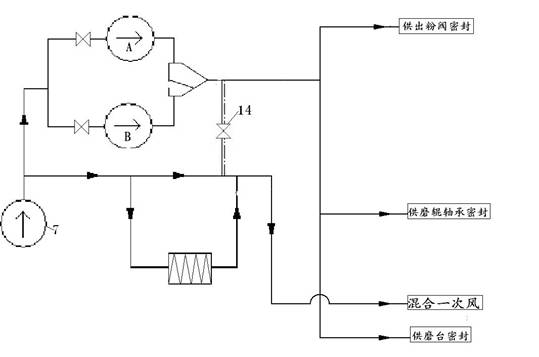

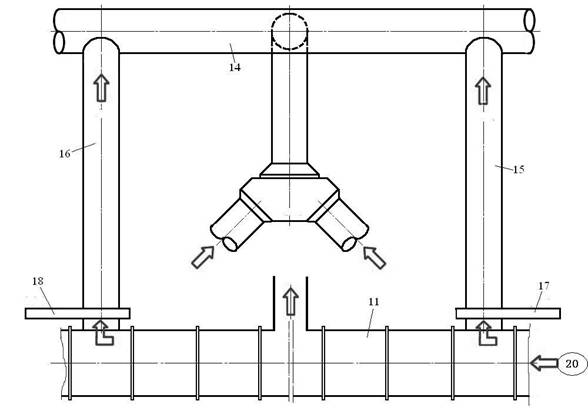

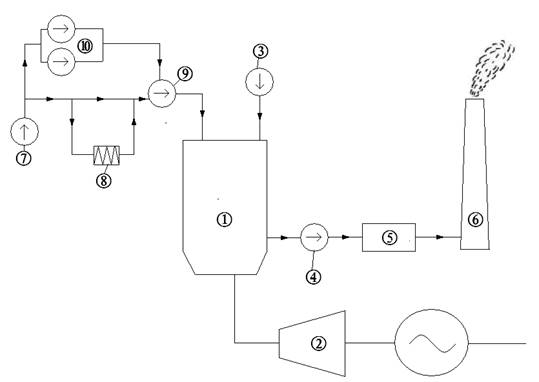

[0025] Such as Figure 4 , Shown in 5, the medium-speed coal mill sealing air system of the thermal power plant of the present invention includes a primary fan 20, a sealing air main pipe 14, a cold primary air main pipe 11, and the like.

[0026] The present invention adopts the cold primary air provided by two primary fans 20 to replace the sealing fan to provide a sealing transformation plan, and the sealing air is sealed by adding at least two left and right pipelines 15 and 16 evenly distributed between A-F coal mills. Main pipe 14 is connected with cold primary air main pipe 11 ( Figure 4 ), the cold primary air at the outlet of the primary fan 20 replaces the original sealing fans 12 and 13 to directly provide the sealing air to the coal mill and the coal feeder, at the connection between the left and right connecting pipes 15, 16 and the cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com