Method and equipment for measuring compressive strength and anti-explosion capability of tubing

A compressive strength, measuring tube technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems that the two ends are not easy to block and the experiment is difficult to carry out, and achieves high work efficiency, simple operation and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

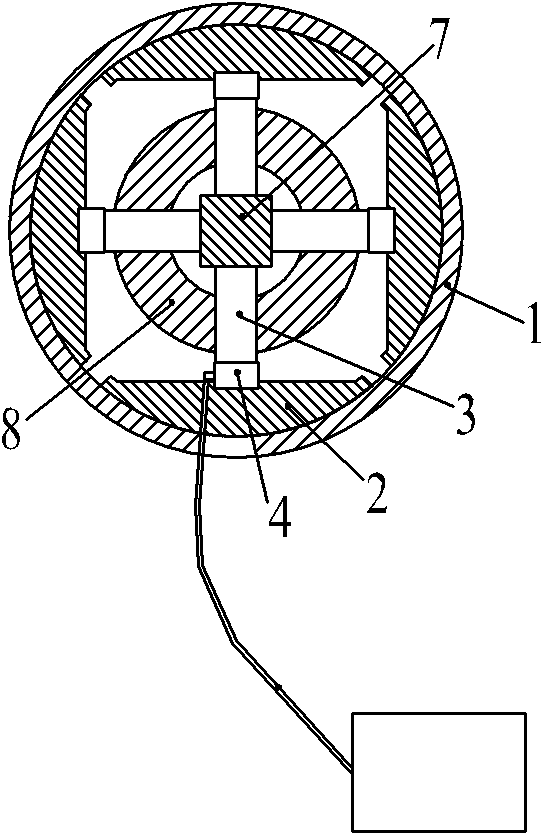

[0022] The method for measuring pipe compressive strength and blast resistance of the present invention comprises the steps:

[0023] a. Prepare the pipe sample and four top plates, measure the inner hole diameter D and length B of the pipe sample, and determine the outer arc surface radius of each top plate according to the inner hole radius of the pipe sample, so that the outer arc surface of each top plate The radius is the same as the radius of the inner hole of the pipe sample, so that the length of each top plate is greater than or equal to the length of the pipe sample, and the outer circular surfaces of all the top plates can be spliced into a ring;

[0024] b. Splice all the top plates into a circle and place them in the inner hole of the pipe sample, so that the inner wall of the pipe sample is in contact with the outer arc surface of each top plate;

[0025] c. Simultaneously apply a force T to each top plate in the radial direction from the inside to the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com