MES (Manufacturing execution system) material deformation method for maximizing yield of specified steel plates

A technology of yield rate and steel plate, which is applied in the information field, can solve the problem of small slab feeding volume and achieve the effect of increasing yield rate, reducing inventory pressure, and reducing the amount of feed material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

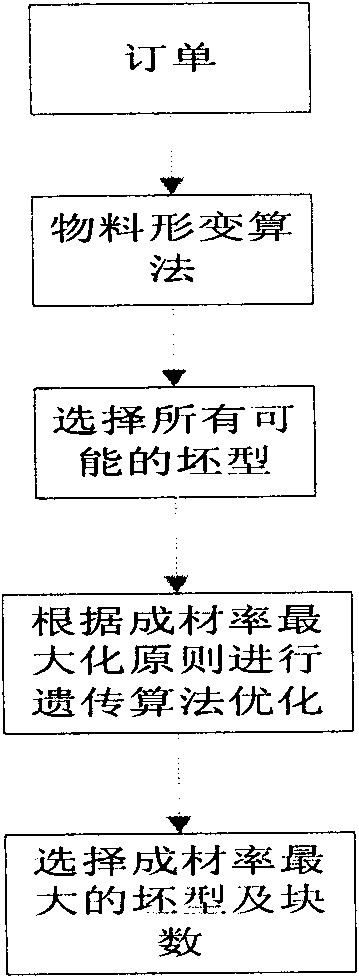

[0041] Figure 1 ~ Figure 3 It is a specific embodiment of the present invention.

[0042] Taking the production data of the plate factory as an example, the customer order requirements: the thickness of the steel plate is 12mm, the width is 3360mm, the length is 11600mm, the number of pieces is 10, and the weight is 36.72 tons. Equipment capacity constraint parameters (unit: mm): 1. Heating furnace constraint: maximum length of slab, burning loss rate; 2. Rolling mill constraint: length, width, thickness of rolled steel plate 3. Shearing line constraint: splitting machine, cutting 4. Technical constraints: width ratio, compression ratio; 5. Quality constraints; 6. Casting machine constraints: slab thickness, width, length, step value of slab length.

[0043] Step 1. According to the order requirements and algorithm parameter setting, write the above parameter records into the initialization module.

[0044] In step 2, the steel plate length constraint check and the steel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com