Ternary doping modified SPEEK proton exchange membrane and preparation method

A technology of proton exchange membrane and exchange membrane, which is applied in the direction of chemical instruments and methods, membrane technology, electrical components, etc., can solve the problems of limiting the application of perfluorosulfonic acid membrane and the decline of proton conductivity, so as to improve the comprehensive performance and improve the proton The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

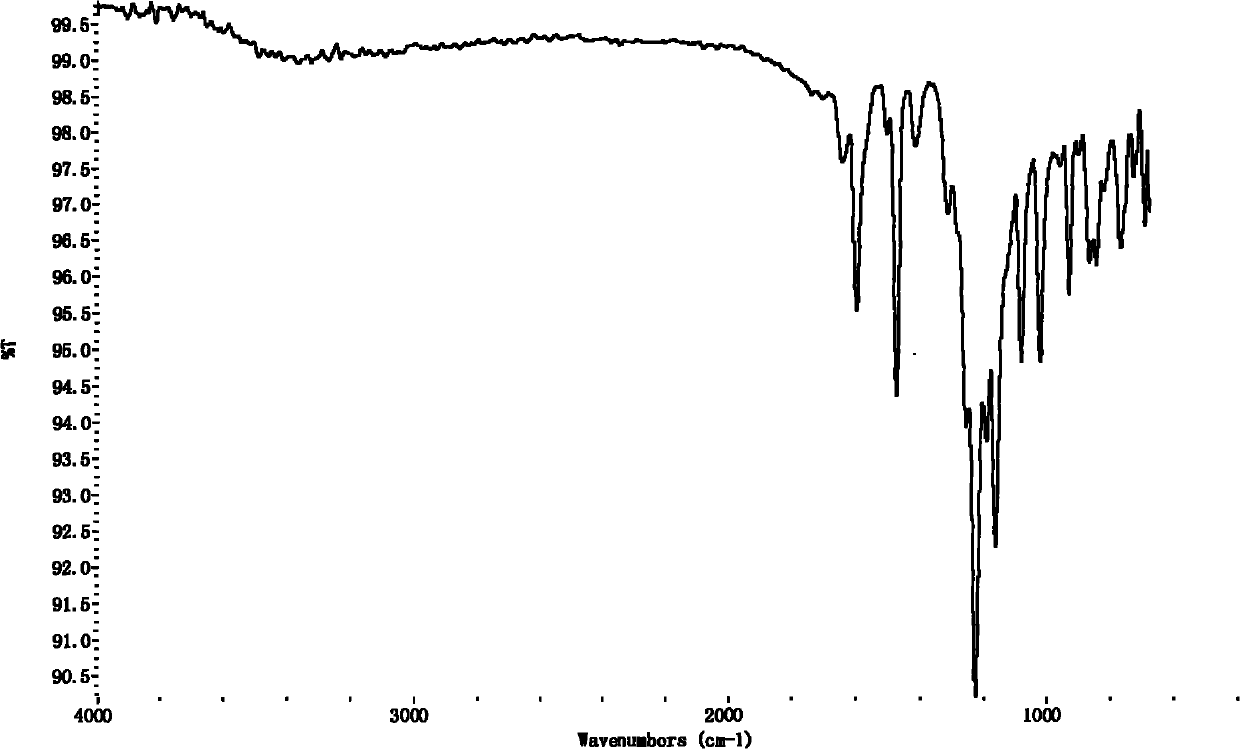

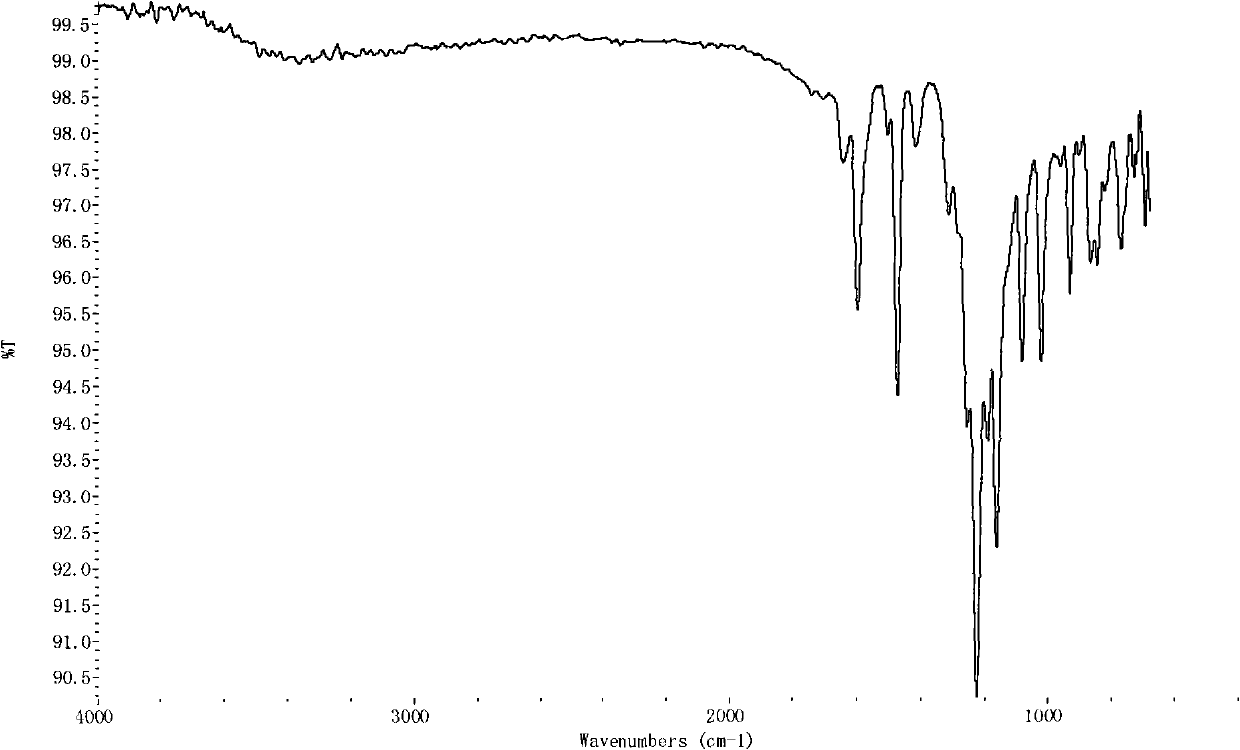

Image

Examples

Embodiment 1

[0026] Embodiment one: the composition formula and preparation process of the present embodiment are as follows:

[0027] 1. Formulation

[0028] A. Composite membrane matrix material: SPEEK material with a sulfonation degree of 40%-80%, and a mass percentage of 80%-98.5%.

[0029] B. Ternary doped solid or liquid: ionic liquid, nano-yttrium oxide and H 3 PW 12 o 40 , the mass percentage is 1.5%-20%.

[0030] 2. Synthesis of SPEEK material with a sulfonation degree of 40%-80%: Add 10g of PEEK powder and 200ml of concentrated sulfuric acid into a 250mL three-neck flask, and mechanically stir the reaction at 60°C for 6h. After the reaction solution is cooled to room temperature, put Pour the reaction solution into 4.5L of ice-water mixture to precipitate the product, wash it with a large amount of deionized water for 5-10 times, and test the product to be neutral with pH test paper. Dry at 100°C for 24 hours and in vacuum at 100°C for 4 hours.

[0031] 3. Pretreatment of t...

Embodiment 2

[0035] Embodiment two: the composition formula and the preparation process of the present embodiment are as follows:

[0036] 1. Formulation

[0037] A. Composite membrane matrix material: SPEEK material with a sulfonation degree of 40%-80%, and a mass percentage of 80%-98.5%.

[0038] B. Ternary doped solid or liquid: ionic liquid, nano-yttrium oxide and H 3 PW 12 o 40 , the mass percentage is 1.5%-20%.

[0039] 2. Synthesis of SPEEK material with a sulfonation degree of 40%-80%: Add 10g of PEEK powder and 200ml of concentrated sulfuric acid into a 250mL three-neck flask, and mechanically stir the reaction at 60°C for 6h. After the reaction solution is cooled to room temperature, put Pour the reaction solution into 4.5L of ice-water mixture to precipitate the product, wash it with a large amount of deionized water for 5-10 times, and test the product to be neutral with pH test paper. Dry at 100°C for 24 hours and in vacuum at 100°C for 4 hours.

[0040] 3. Pretreatment ...

Embodiment 3

[0044] Embodiment three: the composition formula and the preparation process of the present embodiment are as follows:

[0045] 1. Formulation

[0046] A. Composite membrane matrix material: SPEEK material with a sulfonation degree of 40%-80%, and a mass percentage of 80%-98.5%.

[0047] B. Ternary doped solid or liquid: ionic liquid, nano-yttrium oxide and H 3 PW 12 o 40 , the mass percentage is 1.5%-20%.

[0048] 2. Synthesis of SPEEK material with a sulfonation degree of 40%-80%: Add 10g of PEEK powder and 200ml of concentrated sulfuric acid into a 250mL three-neck flask, and mechanically stir the reaction at 60°C for 6h. After the reaction solution is cooled to room temperature, put Pour the reaction solution into 4.5L of ice-water mixture to precipitate the product, wash it with a large amount of deionized water for 5-10 times, and test the product to be neutral with pH test paper. Dry at 100°C for 24 hours and in vacuum at 100°C for 4 hours.

[0049] 3. Pretreatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Methanol permeability coefficient | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Methanol permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com