Topcoat

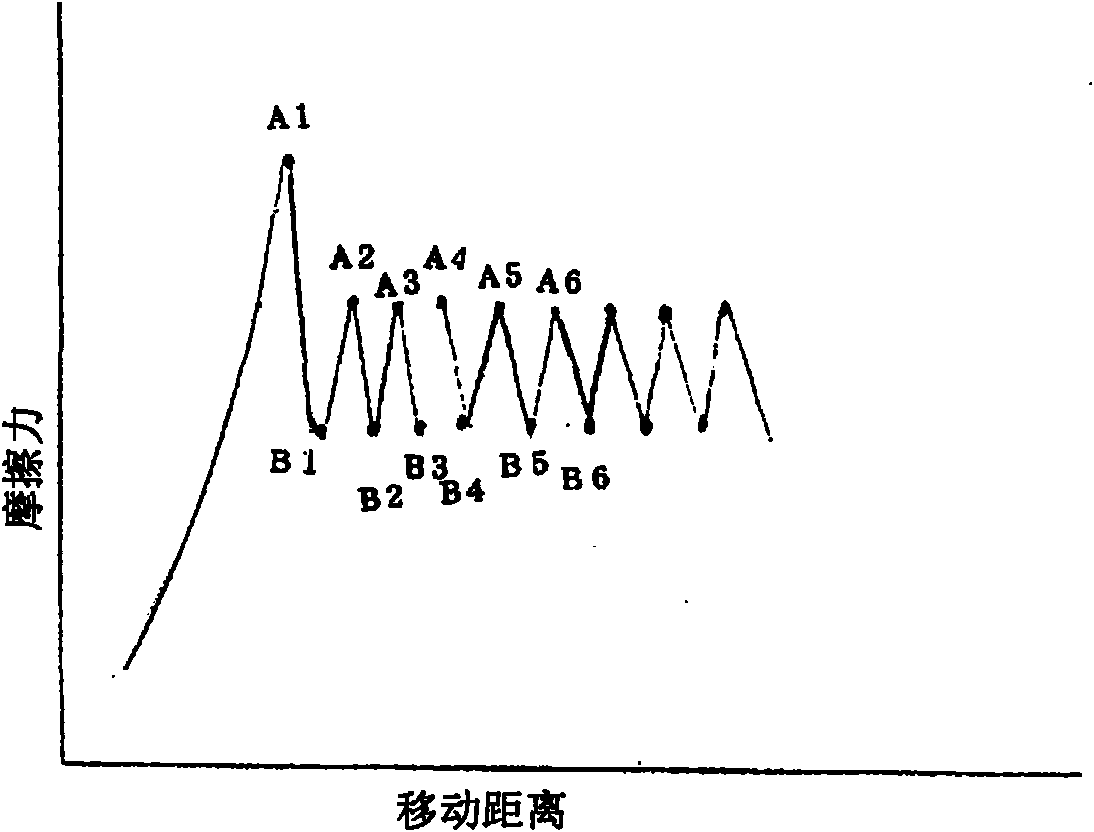

A coating film and weight technology, applied in the direction of coating, leather surface treatment, polyurea/polyurethane coating, etc., to achieve the effect of proper slip resistance and prevention of friction sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0381] About the formation of the primer layer

[0382] (1) An undercoat layer is formed on the surface of a natural leather substrate (with dermabrasion processing). The steps are the following examples.

[0383] The primer layer is the lowest layer of the coating layer, and smooths the unevenness on the leather surface to prepare a layer that stably forms a layer on the upper part. When forming this layer, a composition composed of resin, pigment, auxiliary agent, touch agent, leveling agent and water is applied to the surface of the leather.

[0384] The ratio of resin, pigment and auxiliary agent constituting the solid content is 60:15:25 (total 100%, weight ratio). The resin uses a two-component polyurethane resin. As the pigment, the pigment of the color to be colored is used. Additives include surfactants, thickeners, regulators, matting agents, anti-blocking agents and so on.

[0385] The ratio of resin, pigment, auxiliary agent, touch agent and leveling agent to water is ...

Embodiment 2

[0433] It was the same as in Example 1 until the formation of the primer layer.

[0434] At 40g / m 2 The ratio of coating is made by spraying with a two-component aliphatic polyurethane resin (number average molecular weight: 25000, viscosity 1500mPa·s (25°C)) with a solid content of 35% by weight and 8% by weight based on solid content Two-component aliphatic urethane-acrylic resin, 18% by weight of polyurethane matting agent based on solid content, 26% by weight of crosslinking agent isocyanate based on solid content, and 5% by weight of solid silica particles And a composition for forming a natural leather coating film (solid content to water: 23% by weight to 77% by weight) composed of a silicone touch agent (above solid content) and water at a solid content of 8% by weight.

[0435] Forced to send hot air at 40°C to 50°C to dry it for cross-linking treatment. On the surface of the cow leather is formed a two-component aliphatic polyurethane resin with a solid content of 35% by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com