Cotton seed delinting process method and drying device special for method

A technology of cotton seed delinting and process method, which is applied in the field of drying equipment, can solve the problems of difficult uniform drying of cotton seeds, complicated process, low heat utilization, etc., and achieve the advantages of shortened drying operation time, relatively small volume and reduced cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

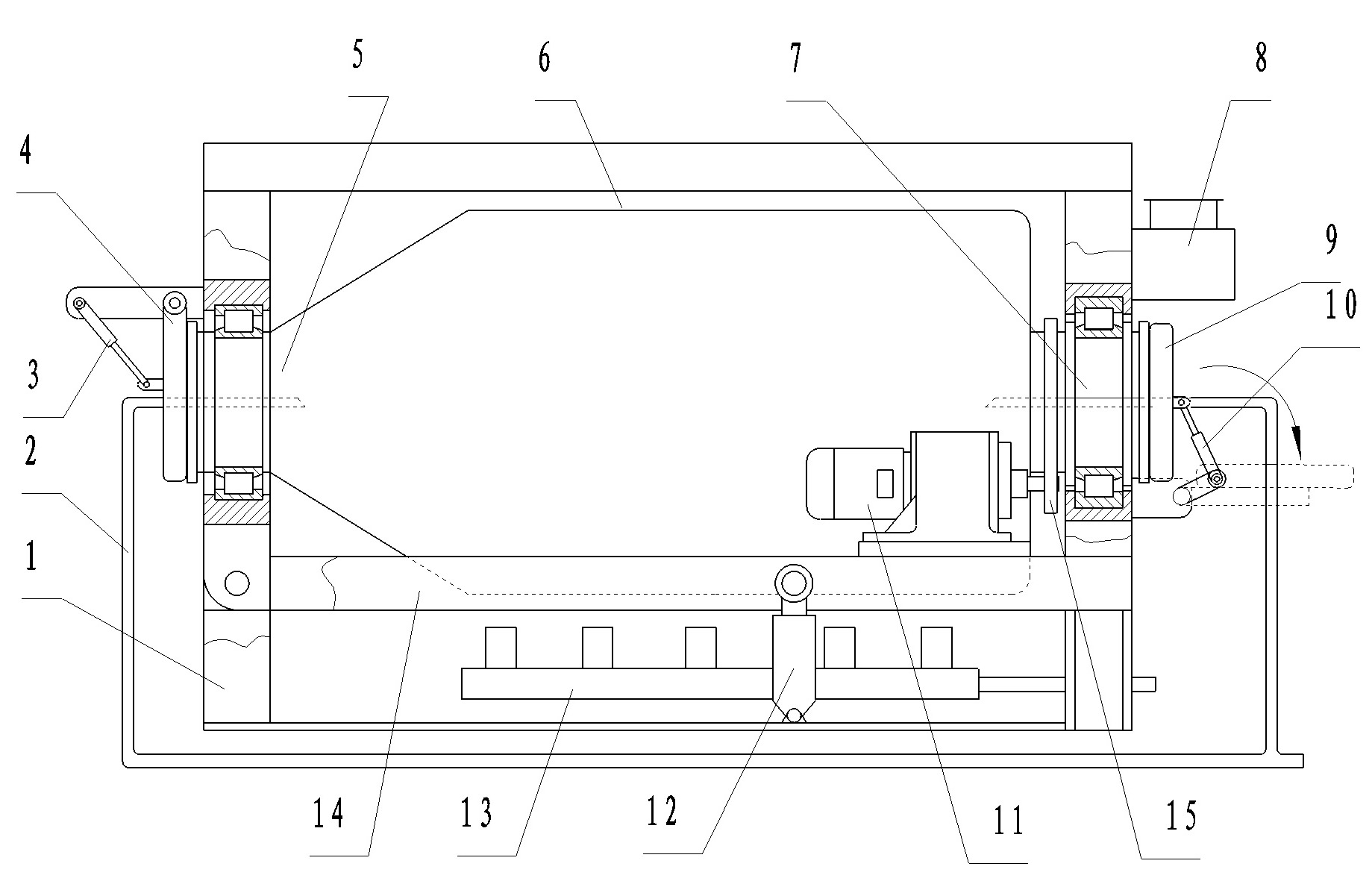

[0030] Embodiment 1: with reference to attached Figure 1~3 , is a schematic structural view of the drying equipment in Embodiment 1 of the present invention. The special device includes a columnar drying drum 6 and a drying drum transmission mechanism 15, and the inner wall of the drying drum 6 is provided with an axial mixing and lifting plate 16, Both ends of the drying drum 6 are respectively provided with a feed port, i.e. a feed port 7 and a discharge port 5, and the feed port 7 is provided with a feed port cover 9 and a feed port cover opening device 10. A dust removal device 8 is also provided above the feed port 7, and the dust removal device 8 is connected with a negative pressure exhaust fan. The discharge port 5 is provided with a discharge port cover 4 and a discharge port cover opening device 3, and the feed port cover is opened. The device 10 and the opening device 3 of the discharge port cover are both hydraulic mechanisms, the feed port 7 and the discharge por...

Embodiment 2

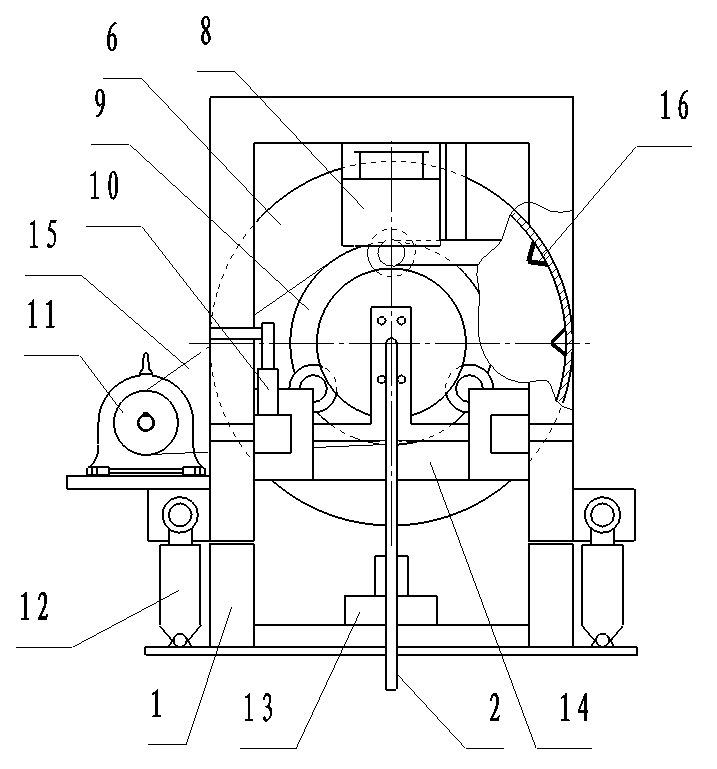

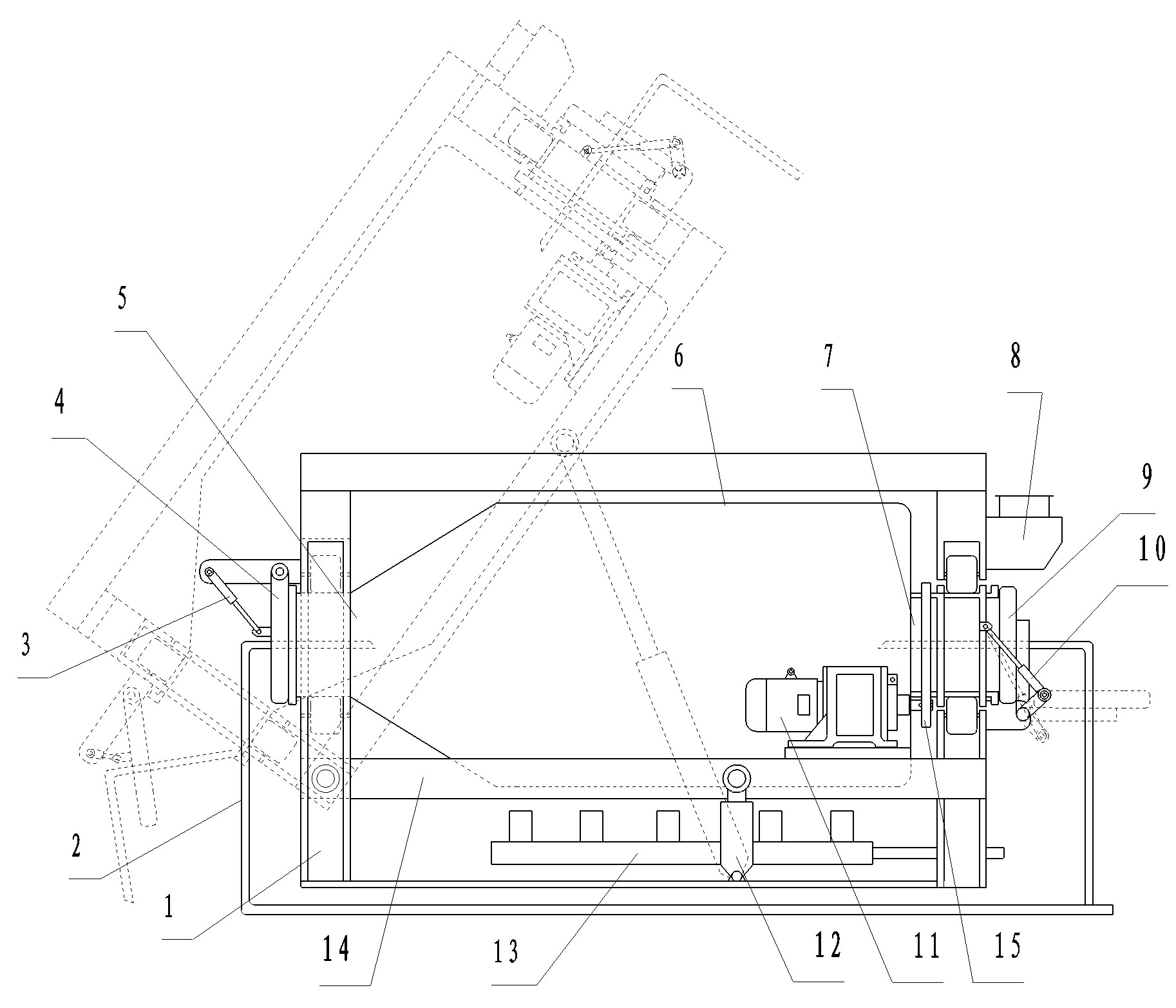

[0032] Embodiment 2: with reference to attached Figure 4~5 , is a schematic structural view of the drying equipment in Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the drying drum transmission mechanism 15 of the special device is a roller transmission mechanism. Two sets of rollers, the drying drum 6 is placed on the rollers, and one end of the outlet 5 of the drying drum 6 is provided with a cylindrical roller bearing and connected to the frame 1 through hinge pins, and the special device The drying drum 6 is provided with a heat preservation cover 17, which is two semi-arc-shaped plates, the bottom of which is hinged on the frame 1, and the top can be interlocked and form a cover on the drying drum 6. When the drying cylinder 6 needs to dump the cottonseed, the two semicircular arc-shaped plates of the heat preservation cover 17 can be separated.

Embodiment 3

[0033] Embodiment 3: with reference to attached Figure 6 , is a schematic structural view of the drying equipment in Embodiment 3 of the present invention. Compared with Embodiment 2, the difference of this embodiment is that the drying drum 6 is only provided with one material opening, that is, the discharge opening 5, and the feeding and discharging share one mouth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com