Method for preparing metal organic frame supported film

A metal-organic framework and membrane-supporting technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. , simplifies the process of film making, and has a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

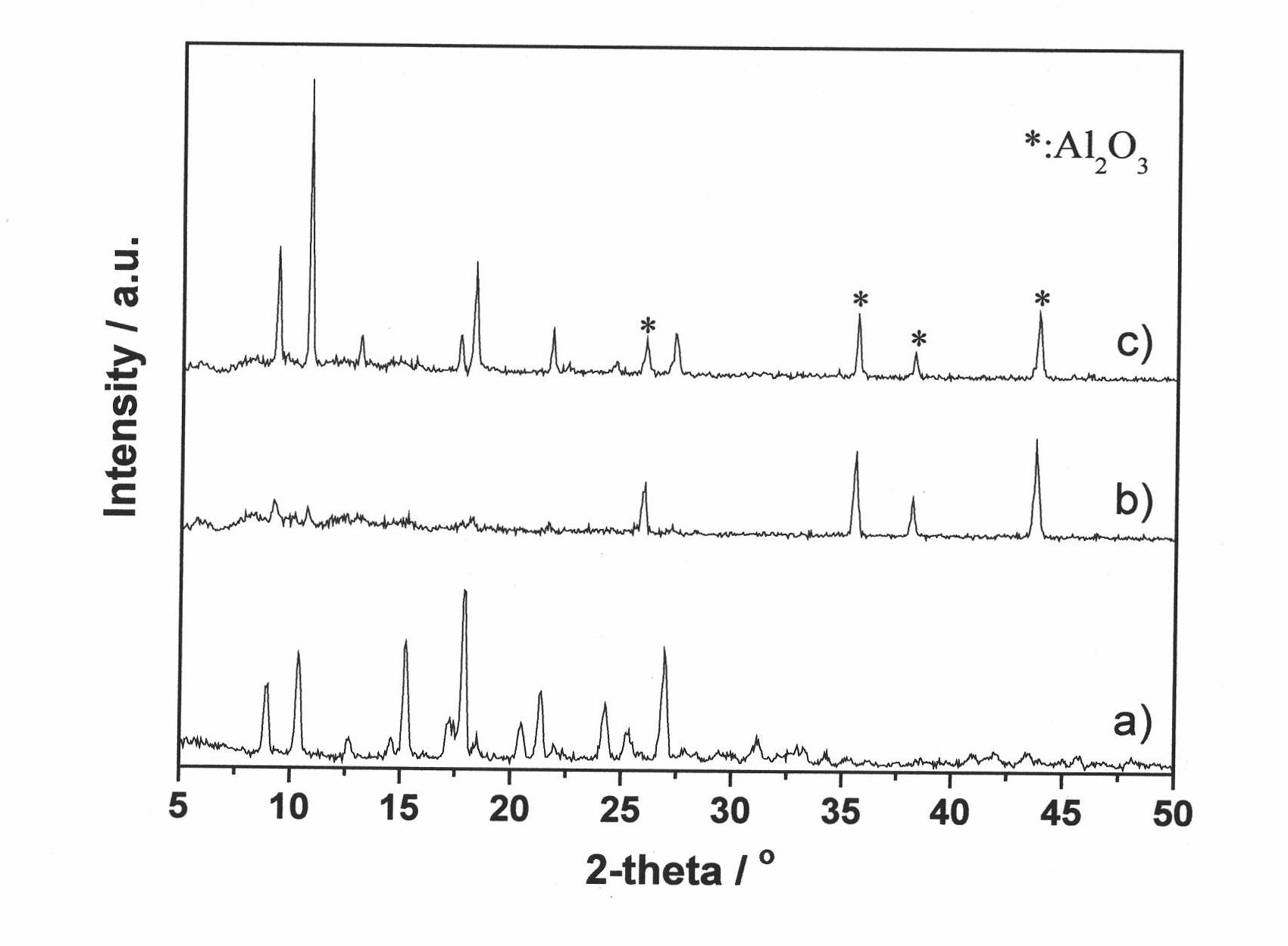

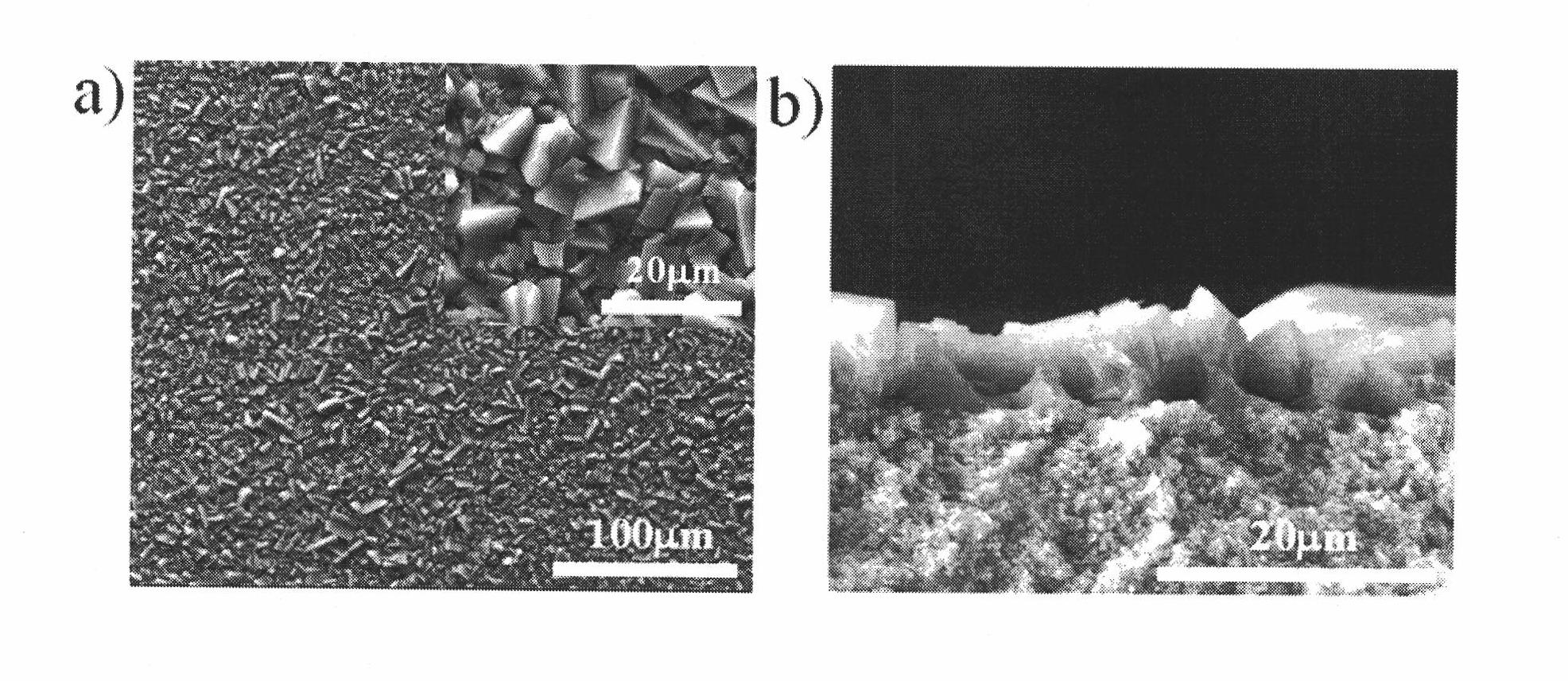

[0033] Adopt the method of the present invention to prepare MIL-53 film and its characterization

[0034] Polish one side of the flat alumina support body smooth, then clean it, soak it in 5% dilute nitric acid and 5% dilute sodium hydroxide solution for 2 hours each, rinse it with deionized water, and dry it. Weigh 0.5g terephthalic acid (H 2 BDC) was poured into 35ml of distilled water and fully stirred, then poured into a 50ml hydrothermal reaction kettle, and put the support body at the same time. Seal the reaction kettle and place it in an oven at 200°C for 20 hours of reaction, then take it out, wash the support body with the seed crystal layer with distilled water after cooling, then put it in the oven at 100°C and dry it to obtain the support body with the seed crystal layer. spare.

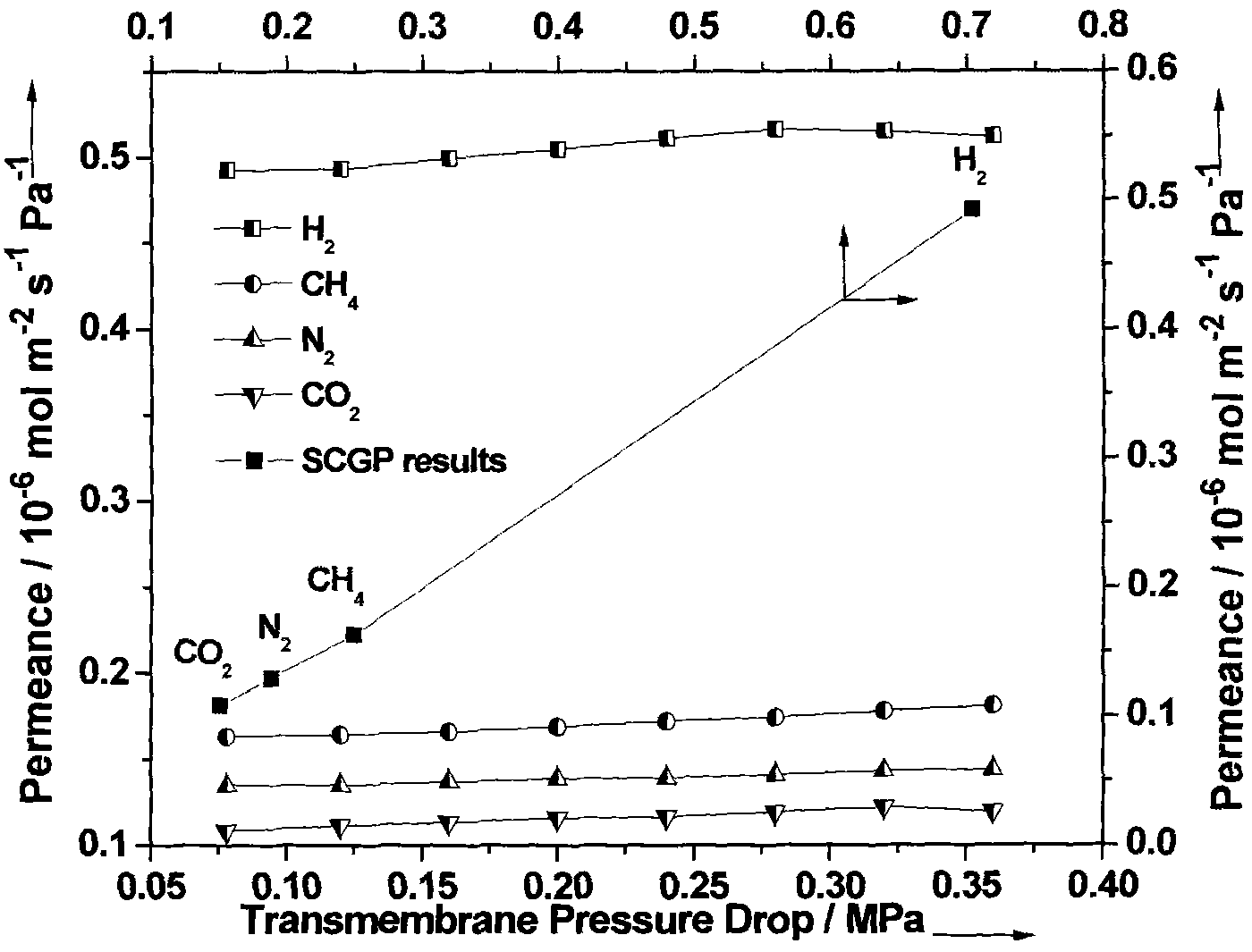

[0035] Weigh 1.0g Al(NO 3 ) 3 9H 2 O and 0.2g H 2 BDC was dissolved in 25 ml of deionized water and stirred well, and this solution was used as a mother solution for the synthesis o...

Embodiment 2

[0040] Adopt the method of the present invention to prepare MIL-96 film and its characterization

[0041] Polish one side of the flat alumina support body smooth, then clean it, soak it in 5% dilute nitric acid and 5% dilute sodium hydroxide solution for 2 hours each, rinse with deionized water and dry. Weigh 0.3g isophthalic acid (H 3 BTC) was poured into 35ml of distilled water and fully stirred, then poured into a 50ml hydrothermal reaction kettle, and simultaneously put into a support body. Seal the reaction kettle and place it in an oven at 220°C for 20 hours of reaction, then take it out, wash the support body with the seed crystal layer with distilled water after cooling, and then put it in the oven at 100°C to dry to obtain the support body with the seed crystal. spare.

[0042] Weigh 1.0g Al(NO 3 ) 3 9H 2 O and 0.2g H 3 BTC was dissolved in 20 ml of deionized water and stirred well, and this solution was used as a mother solution for the synthesis of membranes. ...

Embodiment 3

[0046] Adopt the method of the present invention to prepare MIL-122 film and its characterization

[0047] One side of the flat gallium oxide support was polished smooth, then cleaned, soaked in 5% dilute nitric acid and 5% dilute sodium hydroxide solution for 2 hours each, rinsed with deionized water, and dried. Weigh 0.8g

[0048] 1,4,5,8-naphthalene tetracarboxylic acid (H 4 ntc) into 30ml of distilled water and fully stirred, then poured into a 50ml hydrothermal reaction kettle, and put the support body at the same time. Seal the reaction kettle and place it in an oven at 210°C for 24 hours to react, take it out, wash the support body with the seed crystal layer with distilled water after cooling, and then put it in the oven at 100°C to dry to obtain the support body with the seed crystal layer. spare.

[0049] Weigh 0.45g Ga(NO 3 ) 3 ·xH 2 O and 0.28g H 4 NTC was dissolved in 15ml of deionized water and stirred thoroughly, and this solution was used as the mother s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com