Melamine multilayer solid wood board and processing method thereof

A technology of melamine and processing method, which is applied in the field of building decoration materials, can solve the problems of poor nail-holding force, poor nail-holding force, and poor water resistance of MDF, and achieve good water resistance, low cost, and good nail-holding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

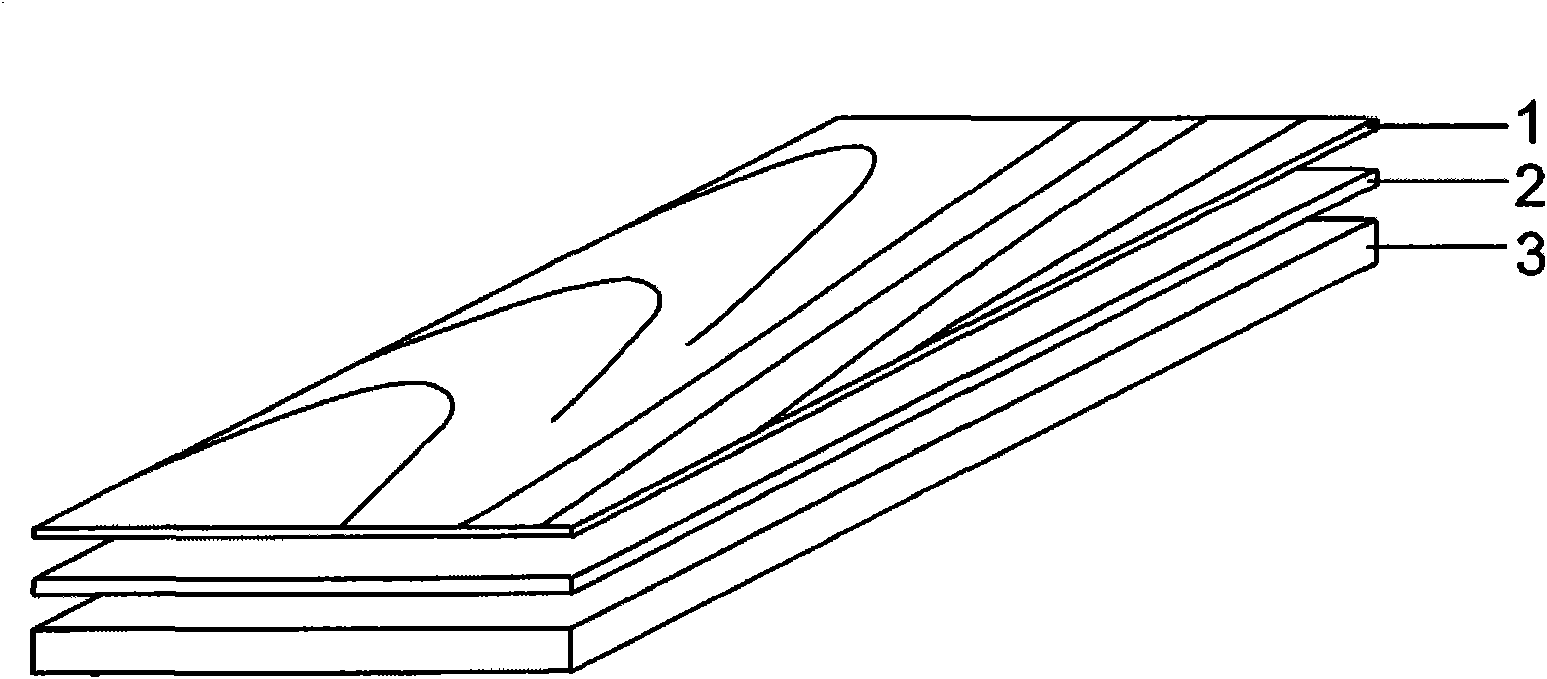

[0031] Such as figure 1 Shown, a kind of melamine solid wood multilayer board, it comprises melamine impregnated decorative paper 1, veneer 2, substrate board 3 successively from surface to inside, described melamine impregnated decorative paper 1, veneer 2, substrate board 3 Composite layers form a whole.

[0032] The veneer 2 can be a natural wood veneer or a recombined decorative wood veneer. In this embodiment, veneer 2 is made of reconstituted decorative material veneer. Reconstituted decorative material refers to the rotary-cut or sliced veneer of artificial forest or common tree species as the main raw material, and the veneer is toned, laminated and glued, and molded. It is a new type of wood decoration material that has the texture, pattern, and tone characteristics of natural precious tree species wood or has art and patterns manufactured by molding technology. The thickness of the recombined decorative material veneer 2 in the present invention may be 0.09-3.0 m...

Embodiment 2

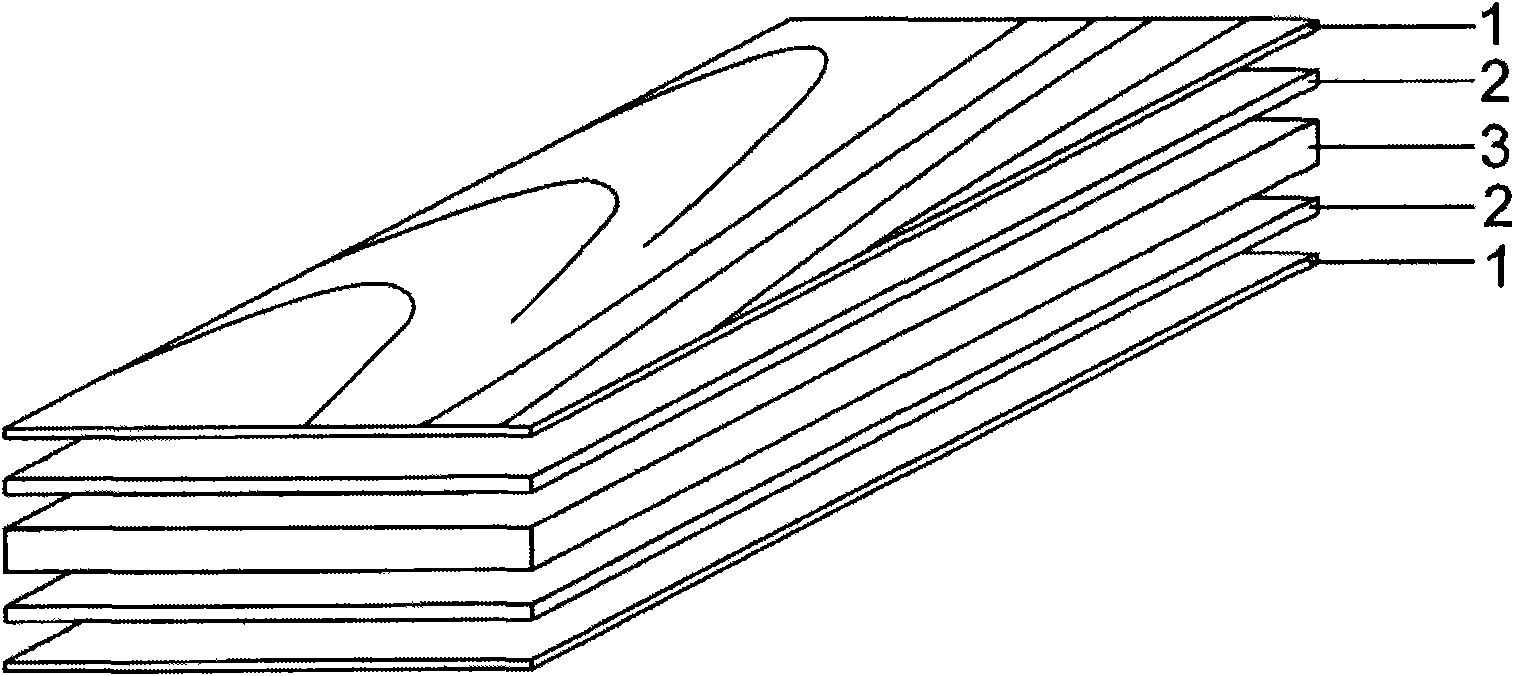

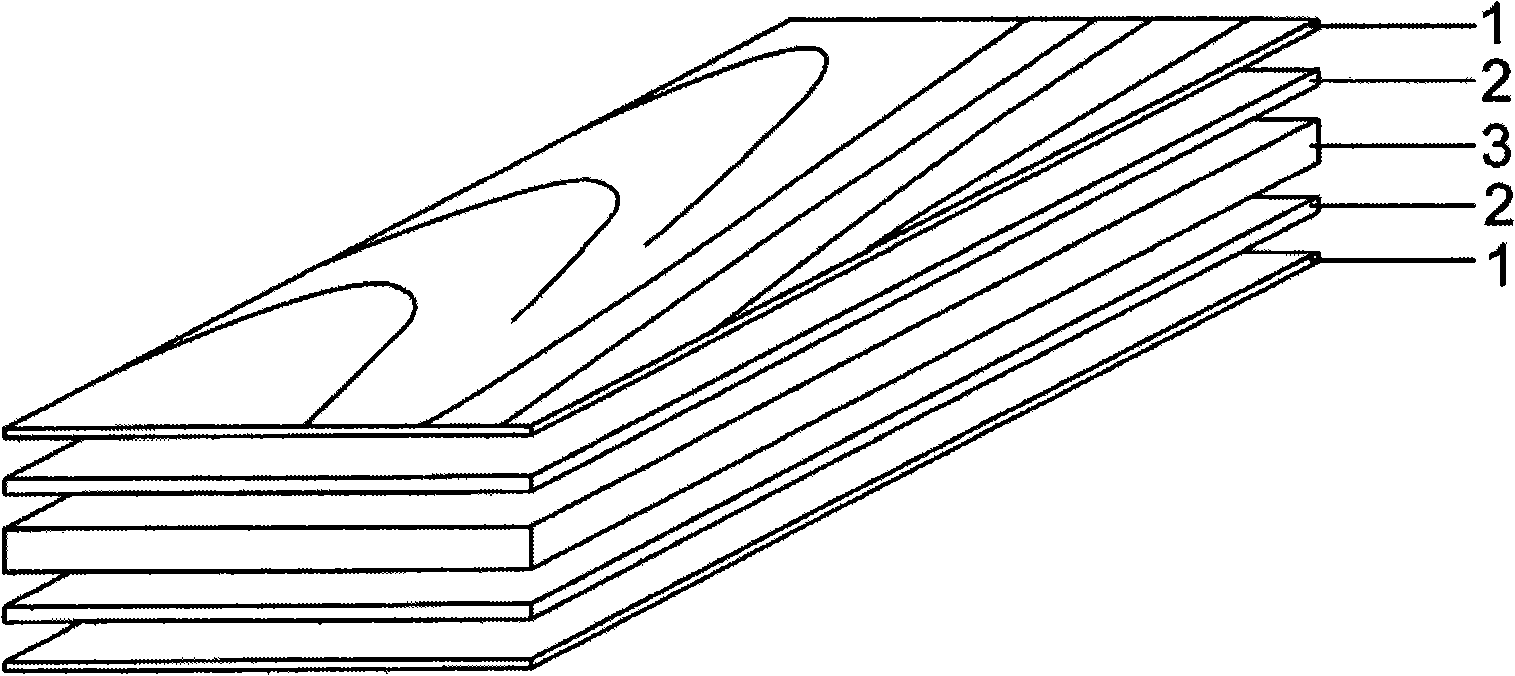

[0035] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that Embodiment 1 is a single-sided product, and this embodiment is a double-sided product, including melamine-impregnated decorative paper 1, veneer 2, substrate board 3, veneer 2, The decorative paper 1 impregnated with melamine is sequentially compounded between layers to form a whole.

Embodiment 3

[0037] A method for processing melamine solid wood multi-layer boards. The melamine-impregnated decorative paper 1 is paved on the surface of a veneer 2, hot-pressed at high temperature to form a veneer decorative paper, and then coated on the surface of a substrate board 3, and pressed into a Melamine solid wood plywood.

[0038] In this embodiment, melamine-impregnated decorative paper 1 is purchased from the market and produced by Dongguan Gaoyi Decorative Materials Co., Ltd., with a gram weight of 80g / m 2 . Lamination temperature of recombined decorative material veneer 2 and melamine impregnated decorative paper 1: 200°C, time: 17S, pressure: 20kg / cm 2 .

[0039] The thickness of the veneer 2 of the recombined decorative material is 2 mm.

[0040] The base plate 3 is made of plywood, with a thickness of 18 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap