Small-diameter restructured structural woods and manufacture technology thereof

A technology of small-diameter wood and structural timber, which is applied in the direction of manufacturing tools, wood processing equipment, and the joining of wooden veneers. It can solve the problems of soft material, low density, and small diameter, and achieve the effect of meeting the specification requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] (1) Preparation of small-diameter recombined wood

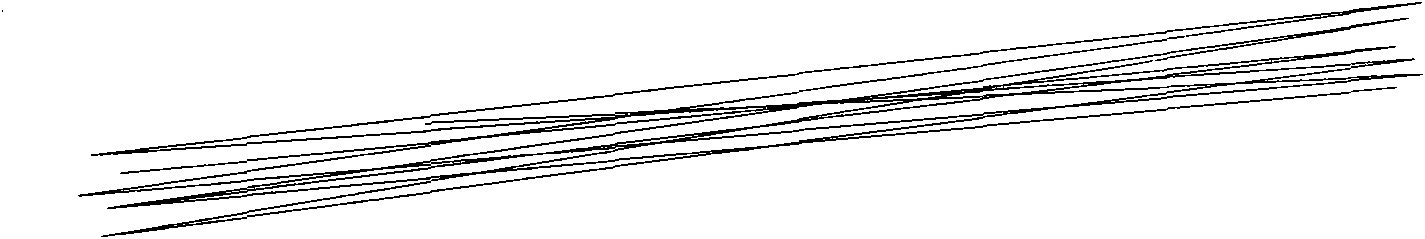

[0033] Cut the small-diameter eucalyptus wood with a diameter of 5cm-10cm into 250cm wood segments, and through fiber separation, form a long wood fiber bundle with a diameter of 2mm-3mm, such as figure 1 As shown, the wood fiber bundles are placed in a drying kiln to dry, so that their moisture content is controlled at 8%-11%, and then they are impregnated in a phenolic resin adhesive with a solid content of 15%. The time is 5 minutes, take it out and drench, so that the amount of glue dipping is controlled at about 12%, and then place the impregnated wood fiber bundles in a drying kiln at a temperature of 50°C, and dry the glued wood fiber bundles until their moisture content is About 12%, according to the direction along the grain, lay a slab with a length of 250cm, a width of 130cm, and a thickness of 13cm-15cm. The pressing pressure is 3.5 MPa, the hot pressing temperature is 170° C., and the holding time is 1.0 ...

Embodiment 2

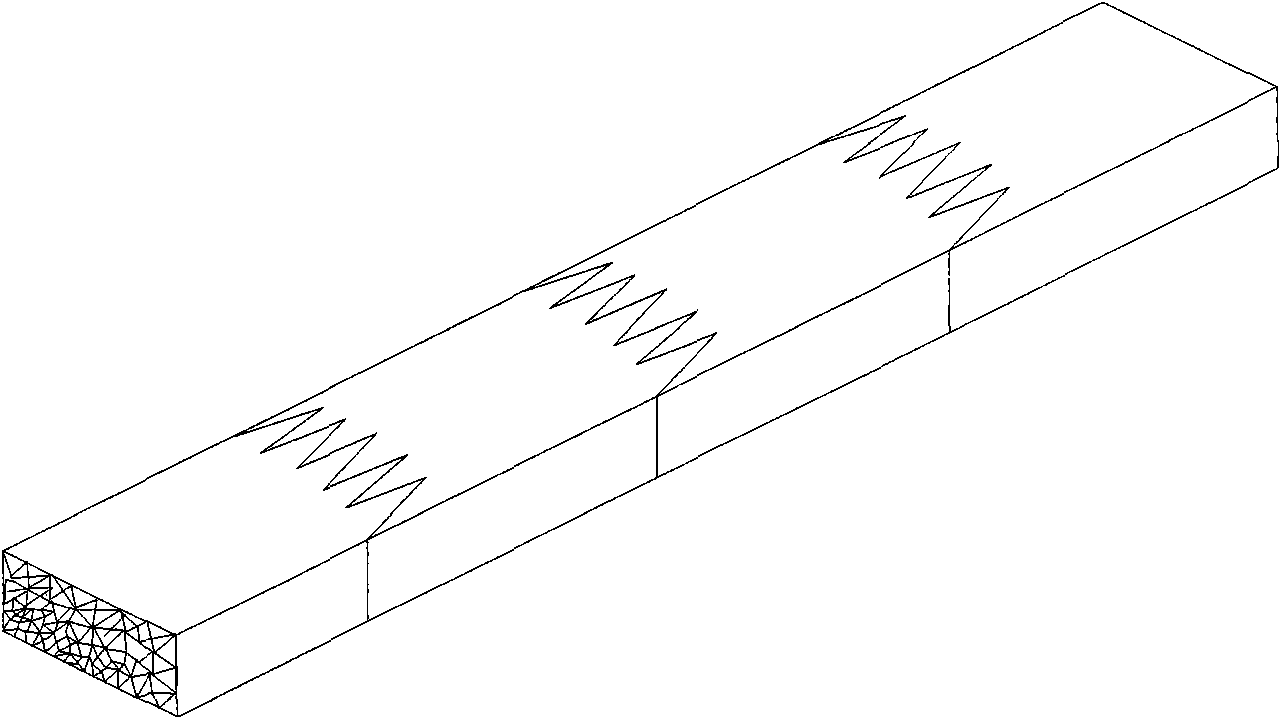

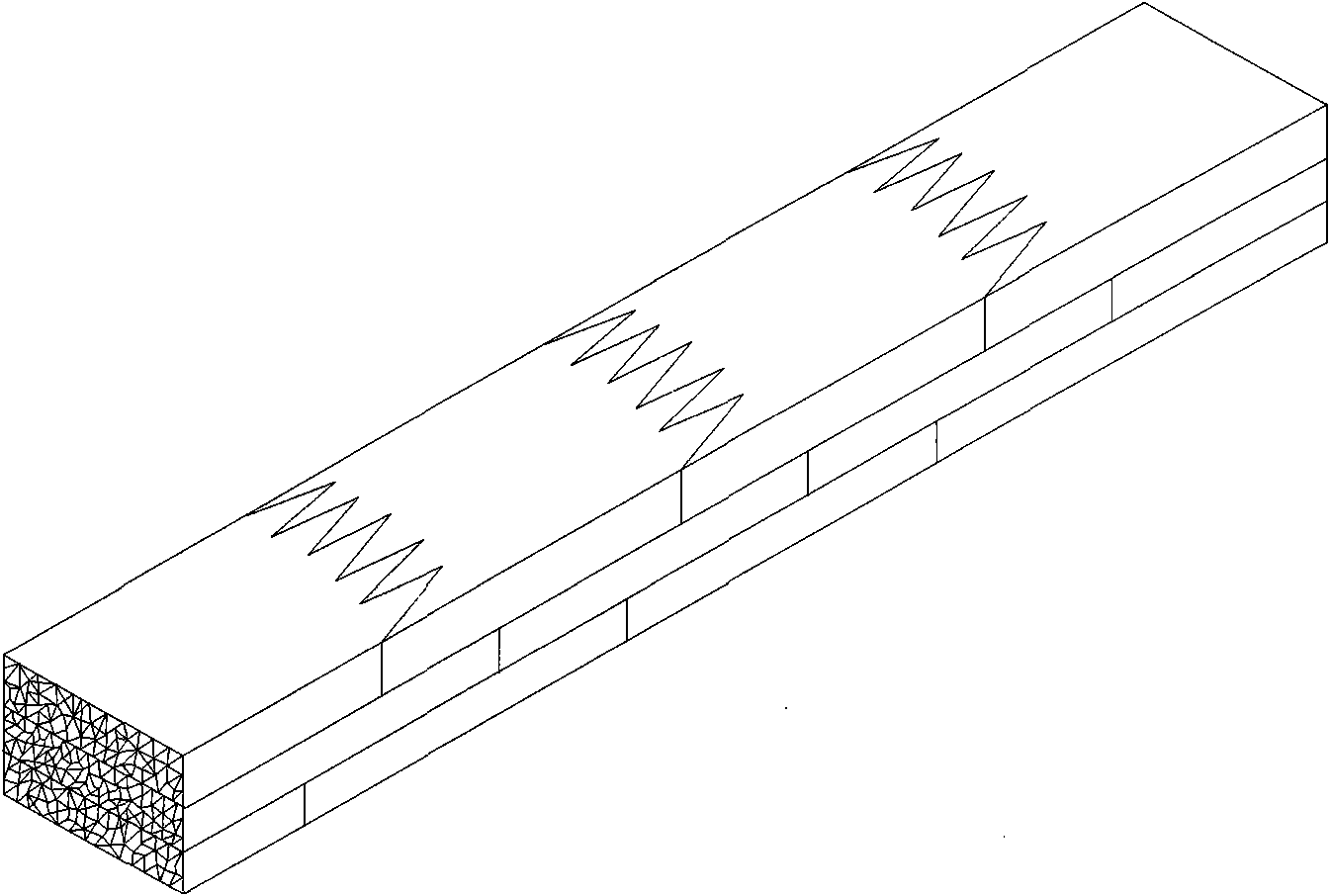

[0041] Method for manufacturing reconstituted structural lumber with misaligned miter joints

[0042] (1) Preparation of small-diameter recombined wood

[0043]Cut the small-diameter fir with a diameter of 5cm-10cm into 190cm wood segments, and through fiber separation, form a long wood fiber bundle with a diameter of 1mm-2mm, such as figure 1 As shown, the wood fiber bundle is placed in a drying kiln to dry, so that its moisture content is controlled at 8%-11%, and then it is impregnated in a phenolic resin adhesive with a solid content of 13%. The time is 3 minutes, take it out and drench, so that the amount of dipping glue is controlled at about 14%, place the impregnated wood fiber bundles in a drying kiln with a temperature of 50°C, and dry the glued wood fiber bundles until their moisture content is 10%. %-11%, according to the direction of the grain, pave a slab with a length of 190cm, a width of 130cm, and a thickness of 15cm-18cm, and send the paved slab into the hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com