Wheel rim driving wheel brake device

A brake device and wheel technology, which is applied to hydraulic brake transmission devices, brakes, brake components, etc., can solve the problems of low braking strength, increased brake pressure response time, and high motor cost, so as to improve the pressure response speed , shorten the braking distance, improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The wheel edge-driven wheel braking device proposed by the present invention can have many different structural forms,

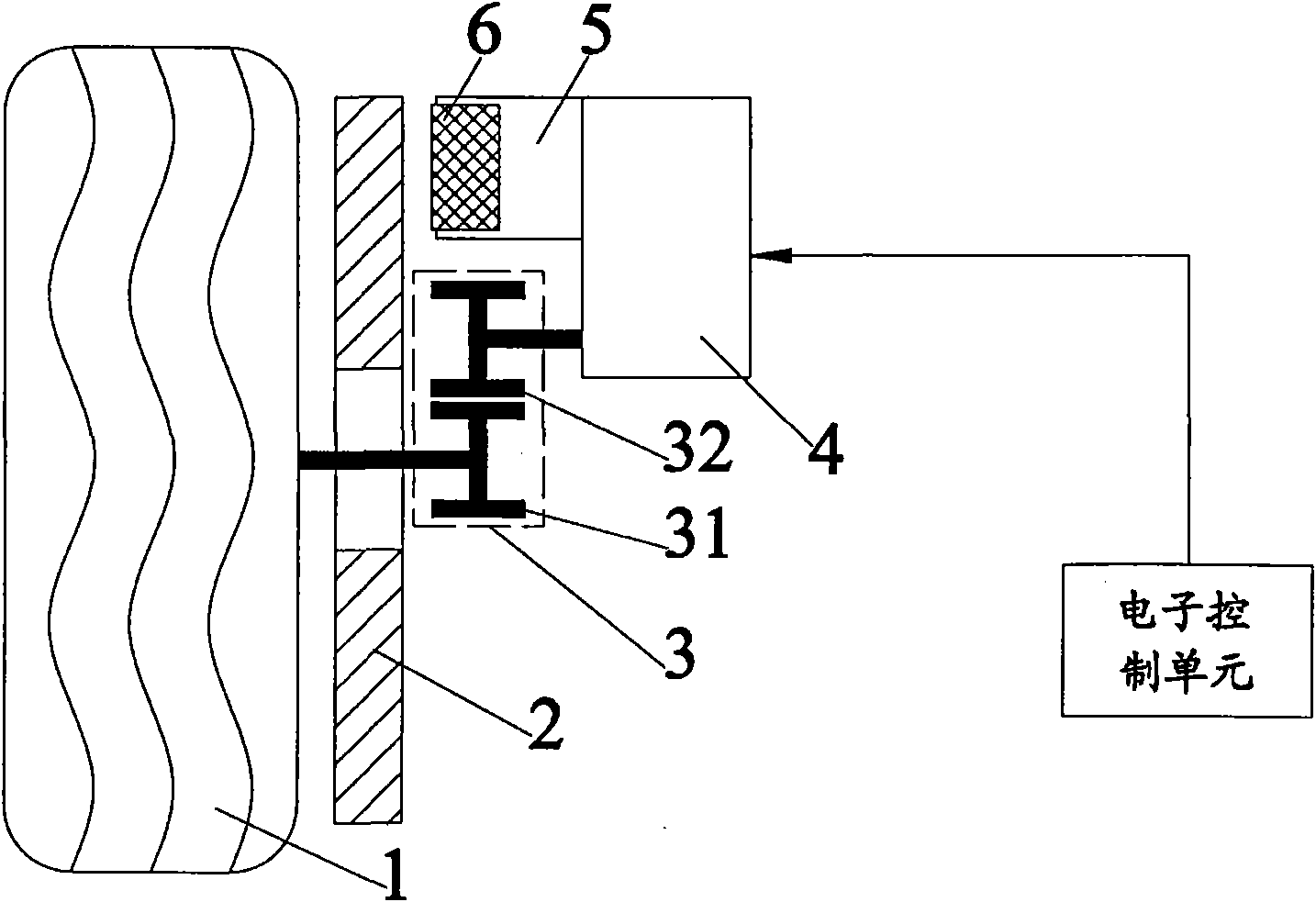

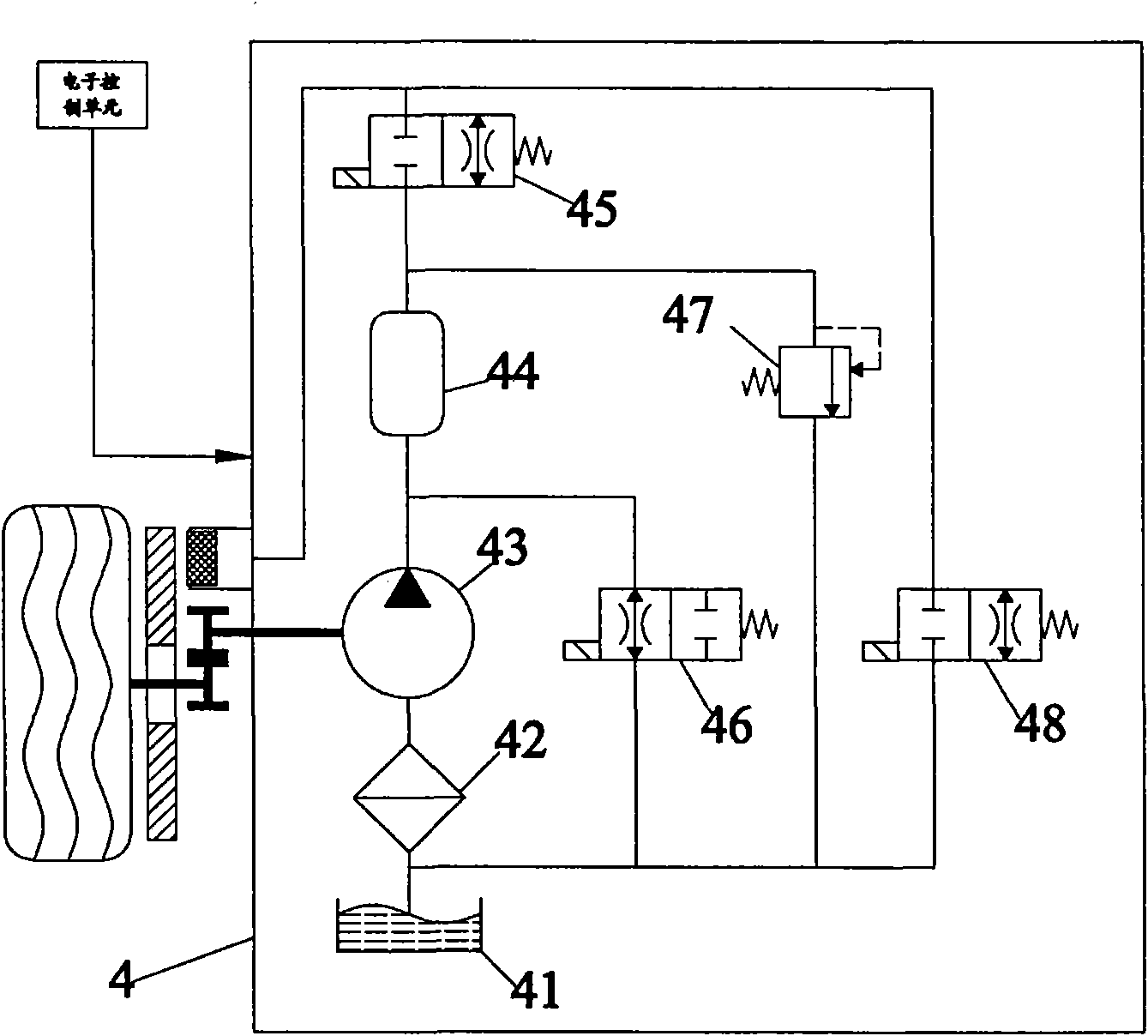

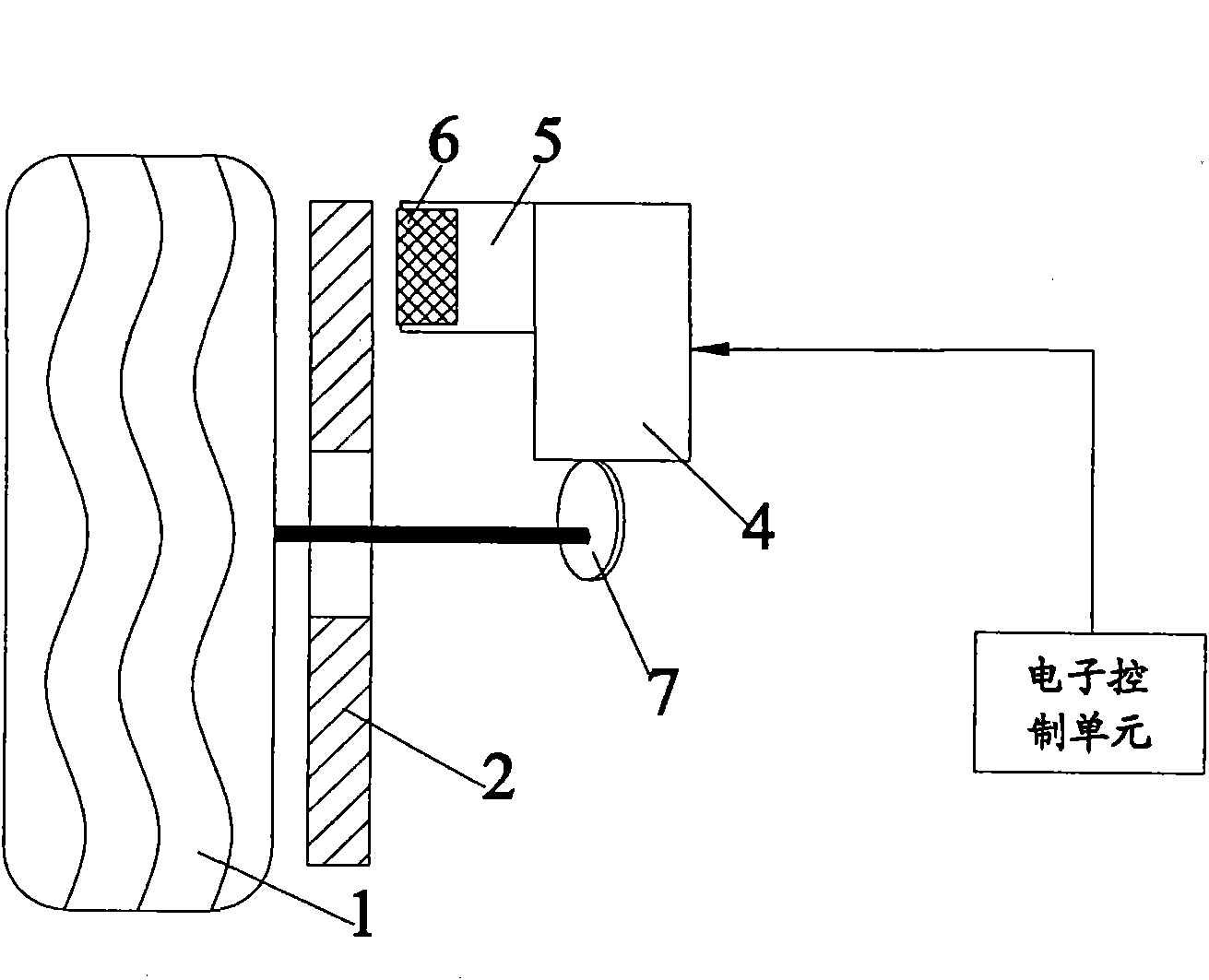

[0025] The braking device of the first structural form, such as figure 1 As shown, it includes: a transmission mechanism 3 for transmitting the kinetic energy of the rotation of the wheel 1 to the wheel hydraulic control unit 4 . Transmission mechanism 3 comprises driving gear 31 and driven gear 32, and driving gear 31 is coaxially installed with automobile wheel 1, and driven gear 32 links to each other with wheel side hydraulic control unit 4; And wheel side hydraulic control unit 4, its structure is as follows figure 2 As shown, it is used to transmit the kinetic energy from the wheel rotation to the brake wheel cylinder 5 of the vehicle according to the instruction of the vehicle electronic control unit. The wheelside hydraulic control unit includes an oil pump, a high-pressure accumulator 44, a discharge valve 46, a boost valve 45, a pressure l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com