Ship propeller

A technology for propellers and ships, applied in ship propulsion, propulsion components, propulsion engines, etc., can solve the problems of low transmission efficiency, high manufacturing difficulty, complex structure, etc., and achieve the effects of low cost, compact structure and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

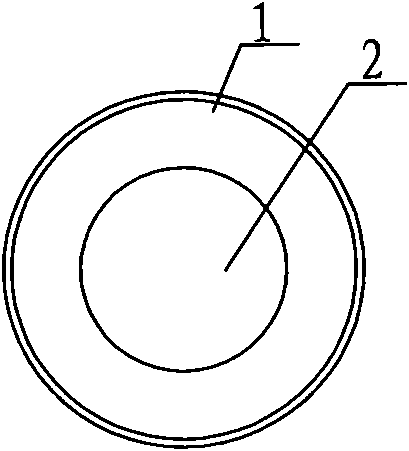

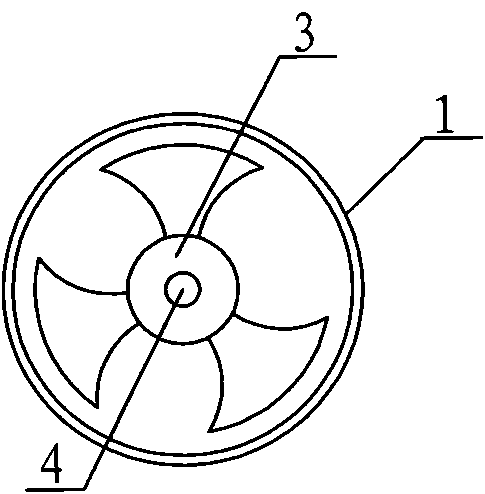

[0031]The cylindrical body 1 of embodiment 1 is made of steel pipe with a diameter of 140 millimeters and a thickness of 3 millimeters, and a length of 450 millimeters. The motor 5 adopts the motor components of the DC submersible pump produced by Zhuhai China Xingye Solar Technology Holdings Co., Ltd. and Zhuhai Xingye New Energy Technology Co., Ltd., the model is: PVP-S12-30D36-0.2, the motor power is 0.2KW, and the working voltage is 36V. Motor 5 also can adopt general AC or DC motor, but waterproof cover will be done well. When using an AC motor, a corresponding power inverter should also be configured when using a DC power supply. Propeller 3 is three blades, 125 millimeters in diameter, casts with steel, and the shaft hole in the middle will cooperate closely with the output shaft 4 of motor 5. Fixed screw rod 6 is made threaded rod with the steel bar of diameter 8 millimeters, and motor 5 is fixed on the central axis of cylinder body 1 through the screw thread on cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com