Complete biodegradation high-tenacity polypropylene carbonic ester compound and preparation method thereof

A polypropylene carbonate and composition technology, applied in the field of completely biodegradable high-toughness polypropylene carbonate composition and its preparation, can solve the problems of material biodegradability, difficulty in maintaining the transparency of PPC, etc., and achieve high complete biological Degradability, high transparency, effect of preventing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a kind of preparation method of above-mentioned polypropylene carbonate composition, comprising:

[0026] Mix polypropylene carbonate, poly 1,2-propylene glycol succinate and maleic anhydride and masticate at 120°C to 140°C to obtain a polypropylene carbonate composition, polypropylene carbonate, poly 1,2 - The mixing ratio of propylene glycol succinate and maleic anhydride is 100:4-100:0.1-1 by weight.

[0027] For the mastication method, the present invention preferably adopts internal mixer blending mastication, and the banburying temperature is set as 120°C to 140°C, preferably as 125°C to 140°C, and the rotating speed is preferably set as 50rpm to 120rpm, and the banburying time is preferably After 5 minutes to 10 minutes, the polypropylene carbonate composition is obtained after extrusion granulation.

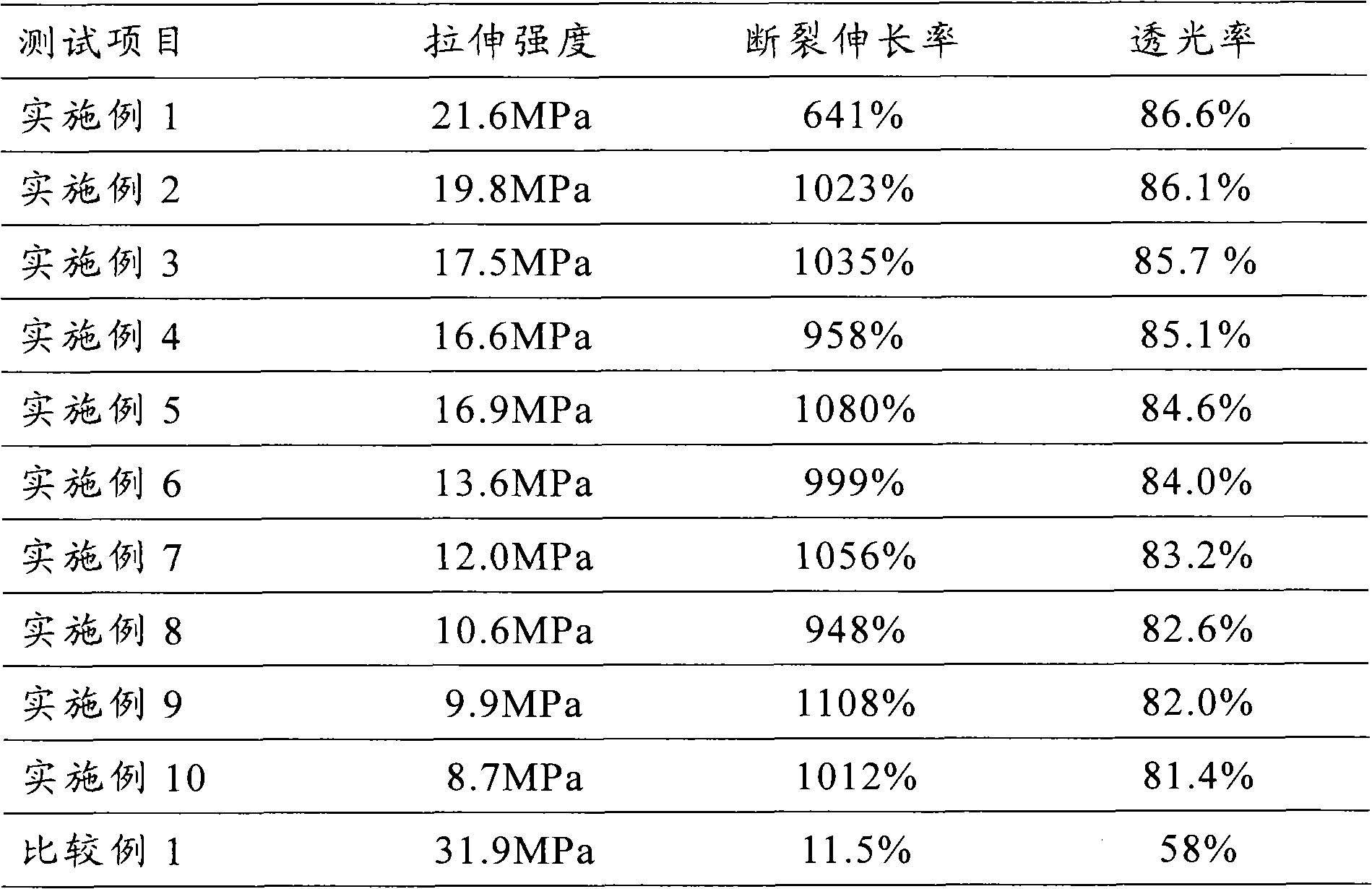

Embodiment 1

[0032] 1. Weigh the following components by weight:

[0033] Polypropylene carbonate 100g

[0034] 4g of poly-1,2-propylene glycol succinate with a number average molecular weight of 800

[0035] Maleic anhydride 0.3g

[0036] 2. Add the above-mentioned polypropylene carbonate, poly-1,2-propylene glycol succinate and maleic anhydride to the internal mixer in sequence, set the temperature of the internal mixer to 140°C, and the rotational speed to 60rpm. After 5 minutes of internal mixing The polypropylene carbonate composition was obtained, and the tensile strength, elongation at break and light transmittance of the polypropylene carbonate composition were measured, and the test results are listed in Table 1.

Embodiment 2

[0038] 1. Weigh the following components by weight:

[0039] Polypropylene carbonate 100g

[0040] 8g of poly-1,2-propylene glycol succinate with a number average molecular weight of 800

[0041] Maleic anhydride 0.1g

[0042] 2. Add the above-mentioned polypropylene carbonate, poly-1,2-propylene glycol succinate and maleic anhydride to the internal mixer in sequence, set the temperature of the internal mixer to 140°C, and the rotational speed to 50rpm. After 5 minutes of internal mixing The polypropylene carbonate composition was obtained, and the tensile strength, elongation at break and light transmittance of the polypropylene carbonate composition were measured, and the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com