Tower solid fermentation device

A solid fermentation device and tower technology, applied in the field of fermentation devices, can solve the problems of large labor workload, thick material accumulation, large energy consumption, etc., and achieve the effects of labor saving, reasonable structure and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

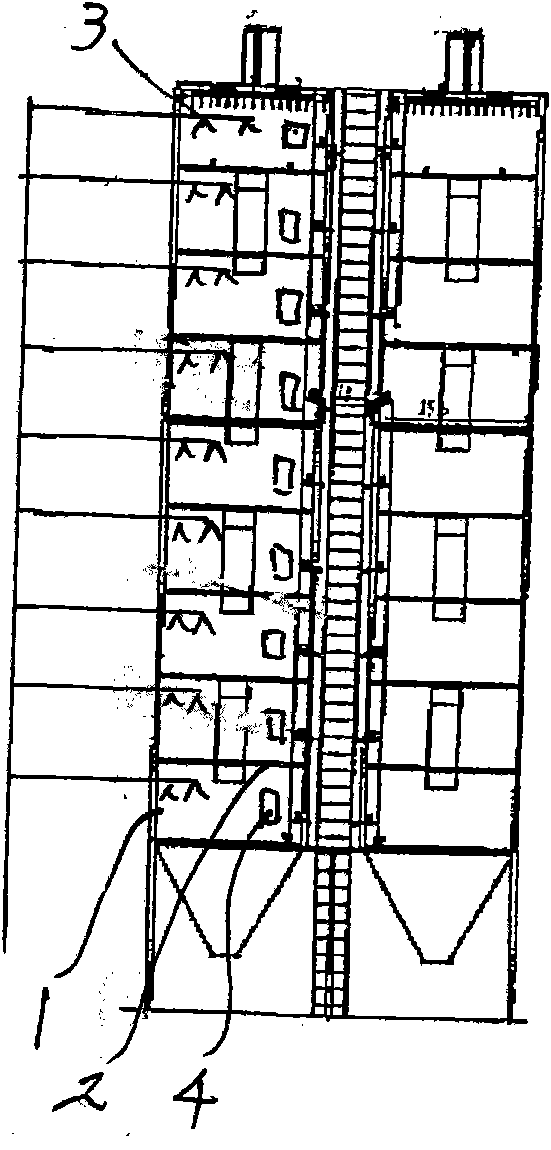

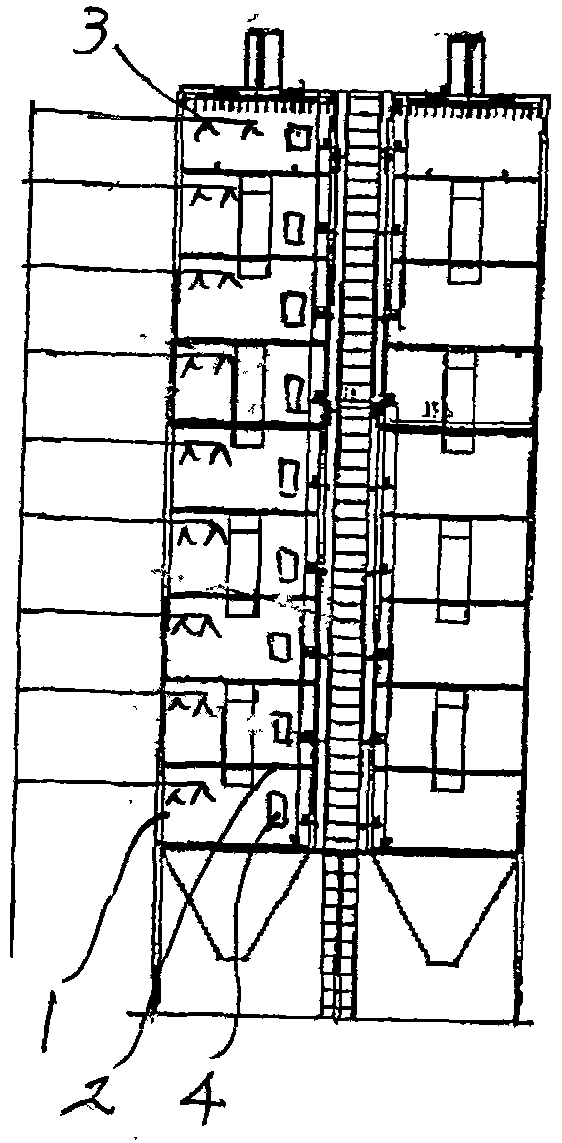

[0017] A tower-type solid fermentation device, including a fermentation bin, the fermentation bin is formed by stacking multi-layer fermentation bins 1, the uppermost layer of fermentation bins is provided with a feed inlet, and the bottommost layer of fermentation bins is provided with a discharge port, A partition 2 is arranged between adjacent two-layer fermentation bins, and the partition is in the form of unloading the fermentation material into the lower fermentation bin. The partition is in the form that the fermented material can be unloaded into the lower fermentation bin, which means that the partition is in two halves of a downward split type (or a part of the downward opening type or a drawer plate type or is equipped with a material scraping device). Hole form or overall downward single opening or combined downward opening). The entire fermentation silo is in a movable form (or in the form of a fixed structure, building, etc.). Nutrient solution or strain sprayin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com