Fused salt electrosynthesis method of hydrogen storage alloy containing magnesium, lithium, sodium and potassium

A technology of hydrogen storage alloy and electrosynthesis, which is applied in the field of preparation of AB3 type hydrogen storage alloy, can solve the problem that there is no technical report on adding sodium and potassium to hydrogen storage alloy, and there is no report on the addition of magnesium, lithium, and sodium to electrosynthesis. and potassium issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In MmNi 24.5 Al 51.5 Electrosynthesis of AB by Molten Salt Electrosynthesis Added Magnesium and Lithium to Hydrogen Storage Alloy 3 Type hydrogen storage alloy method, the step, condition and operating method of its electrosynthesis method are:

[0058] Step 1: Miscible Molten Salt Electrolyte:

[0059] (1) The formula of the four mixed salt components of the molten salt electrolyte is: 50wt.% KCl-50wt.% NaCl, the meaning of this expression is: the mixed salt in KCl·NaCl binary mixed salt is composed of 50wt.% The first component KCl is mixed with 50wt.% of the second component NaCl by equal weight, and the sum of the two weight percentages is 100%;

[0060] The second group: 60wt.% KCl-40wt.% MgCl 2 , the meaning of the expression is: KCl MgCl 2 Binary mixed salt is based on 60wt.% of the first component KCl and 40wt.% of the second component MgCl 2 The ratio of weight percentage is mixed, and the sum of the two weight percentages is 100%;

[0061] The third gro...

Embodiment 2

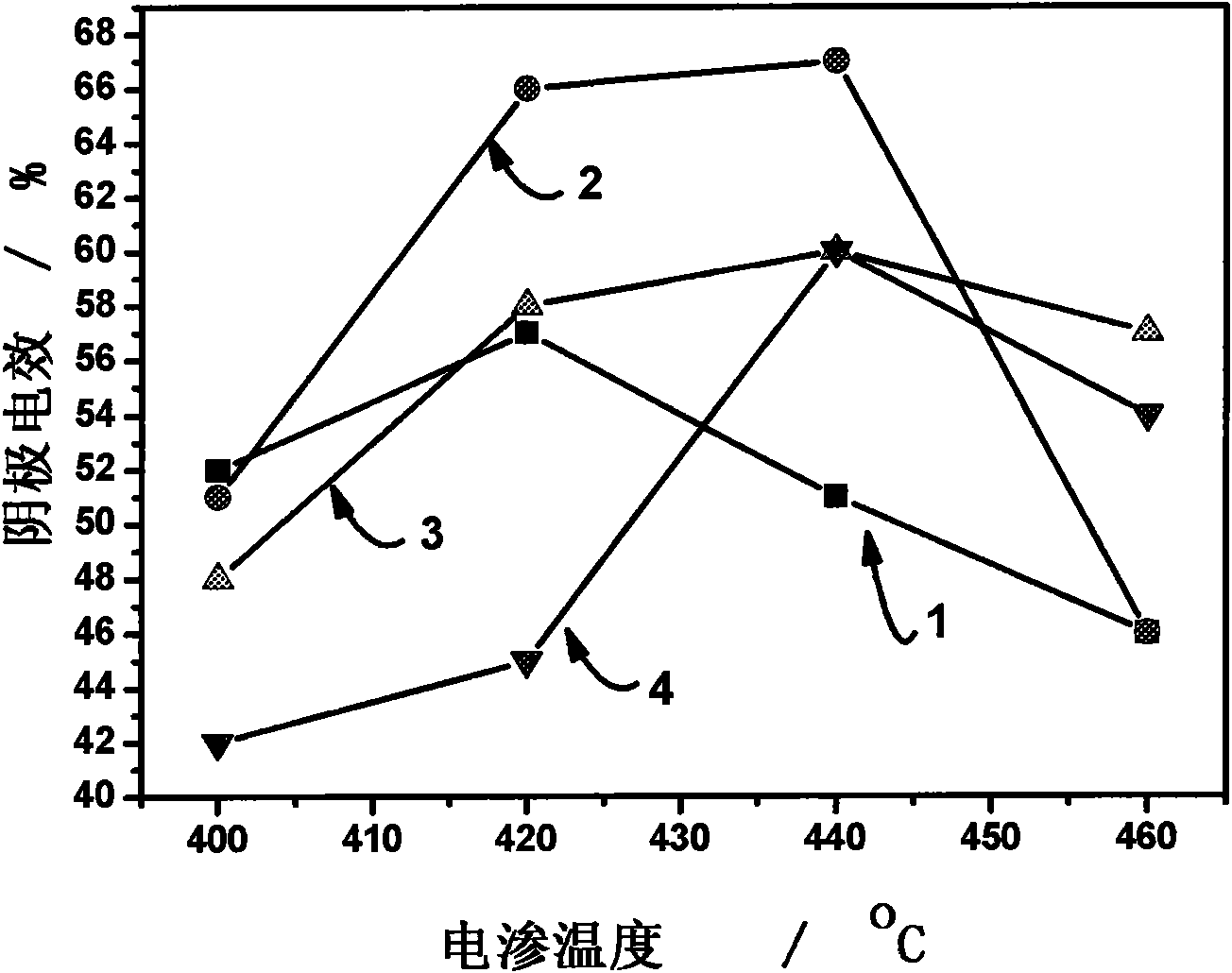

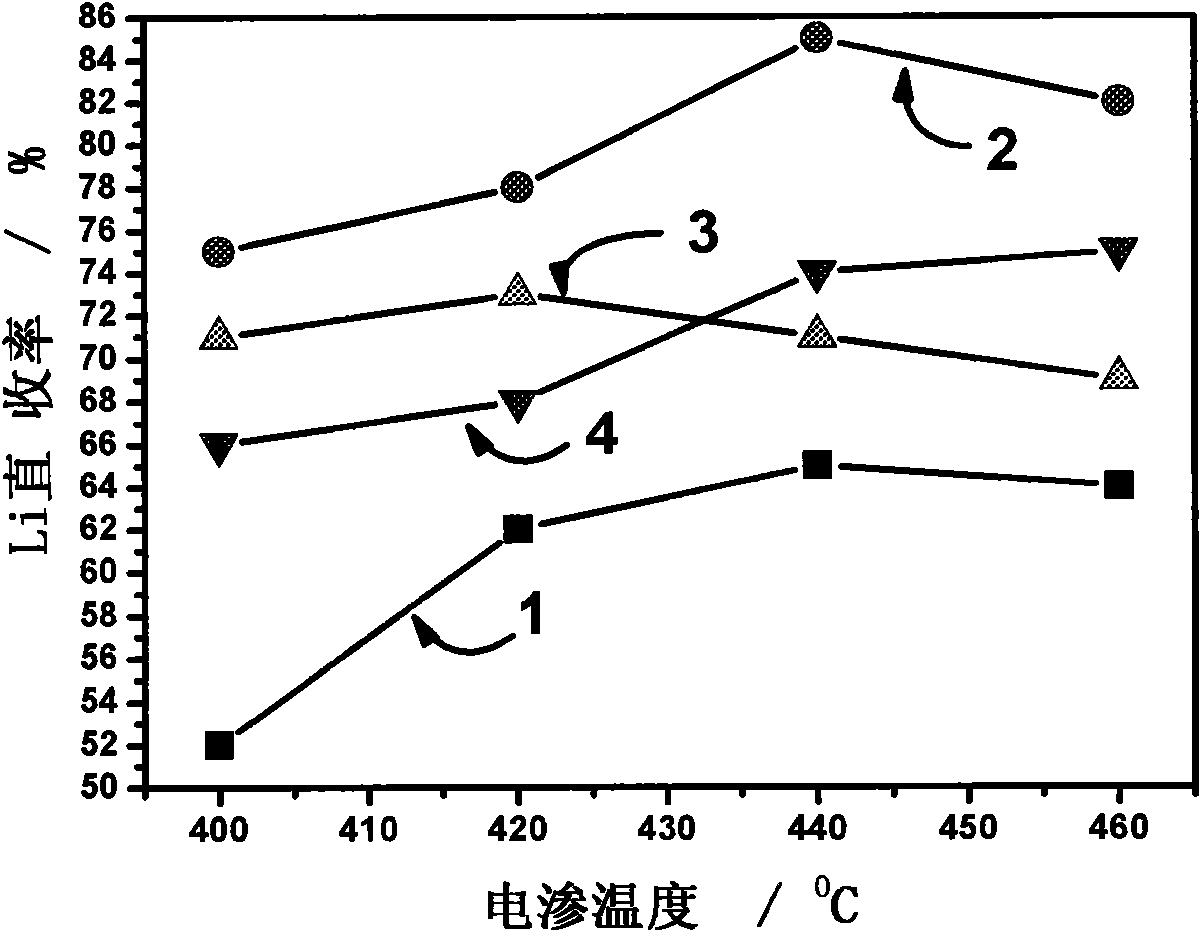

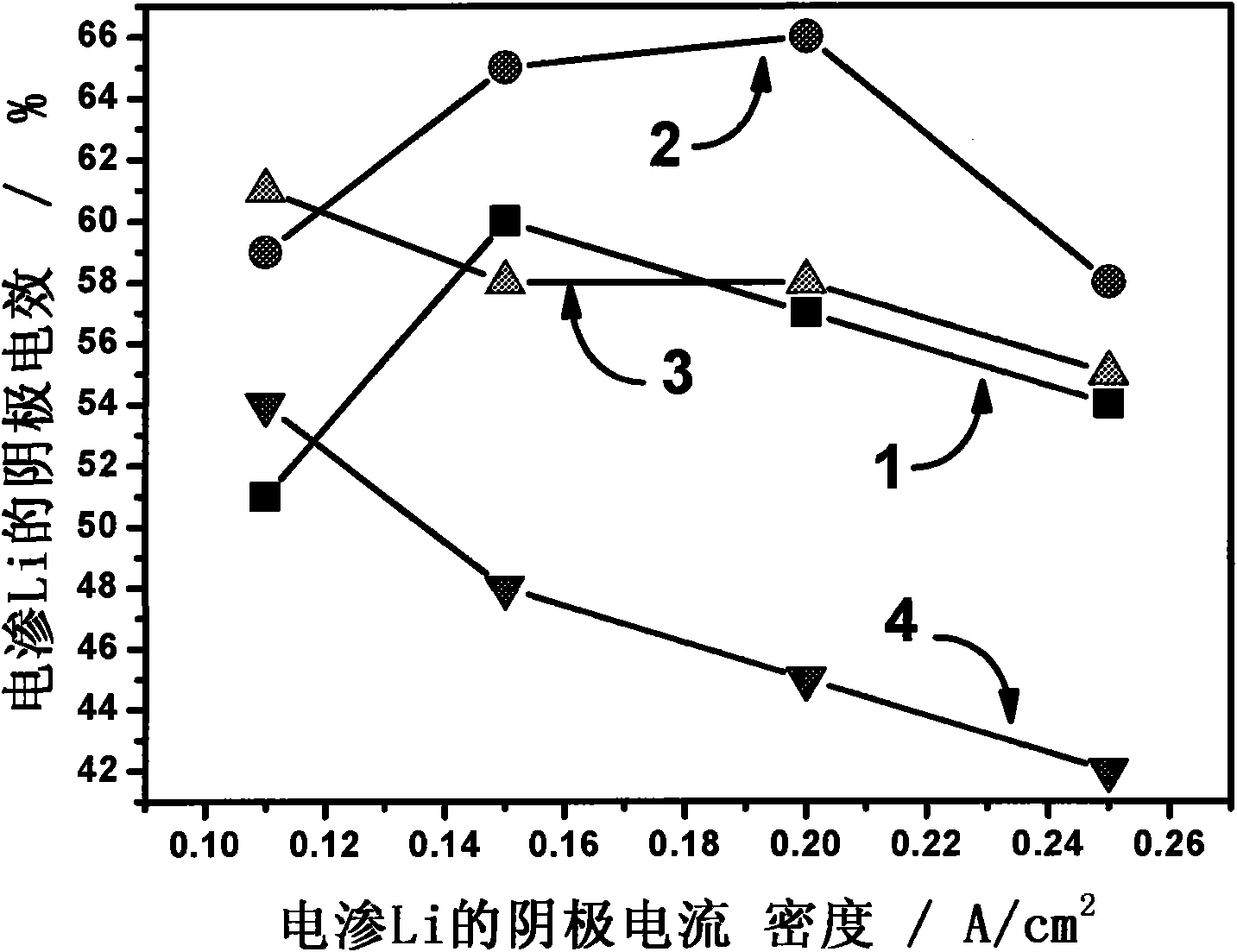

[0091] The difference from Example 1 is: 1. the time of electroosmosis Li is shortened to 1 / 60 of that of Example 1; the electrolysis time of adding Mg, Na and K to electrolysis increases by 4 times that of Example 1; 2. the temperature of electroosmosis Li 450℃; electroosmotic Li cathode current density is 0.20A / cm 2 ;; ③ The electrolysis temperature of electrolysis plus Mg, Na and K is 750°C; the cathode current density of the electrolysis is 22A / cm 2 ; ④ Li in the electrosynthesized alloy accounts for 0.057wt.% by weight; K and Na account for 84ppm and 126ppm in the electrosynthesized alloy; ⑤ Li direct yield is 76%; The cathodic current efficiency is 65%; 6. The cathodic current efficiency of electrolysis plus Mg, Na and K is 70%; the direct recovery rate of Mg is 87%; Induction heating for 2 minutes; ⑧After induction heating, K and Na in the electrosynthesized alloy were reduced from 84ppm and 126ppm to 5ppm and 7ppm; ⑨After induction heating, the chemical formula of the...

Embodiment 3

[0093] The difference from Example 1 is: 1. The composition of hydrogen storage alloy cathode powder is from the MmNi of Example 1 24.5 al 51.5 with MmNi 8.75 al 1.25 The time of electroosmosis Li is shortened to 1 / 3 of embodiment 1 relative to embodiment 1; The electrolysis time of electrolysis adding Mg, Na and K increases 1 times of embodiment 1; 2. the temperature of electroosmosis Li is 440 ℃; electroosmotic Li cathode current density is 0.25A / cm 2 ; ③ The electrolysis temperature of electrolysis plus Mg, Na and K is 735°C; the cathode current density of the electrolysis is 20A / cm 2 ,; ④ Li accounted for 0.66wt.% by weight in the electrosynthesized alloy; Na and K accounted for 240ppm and 189ppm by weight in the electrosynthesized alloy; ⑤ Li direct yield was 74.2%; The cathodic current efficiency of electrolysis is 63%; 6. the cathodic current efficiency of electrolysis adding Mg, Na and K is 59%; The direct recovery rate of Mg is 81%; Induction heating for post-pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com