Pressure and the output self-adaptation measurement and control system of electric pump producing well

A measurement and control system and technology for oil production wells, applied in pump control, measurement, and production of fluids, etc., can solve problems such as affecting oil production at the bottom of the well, adjusting the production of electric pump wells, and automatically adjusting equipment, so as to protect normal operation and ensure production. The effect of maximizing output and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

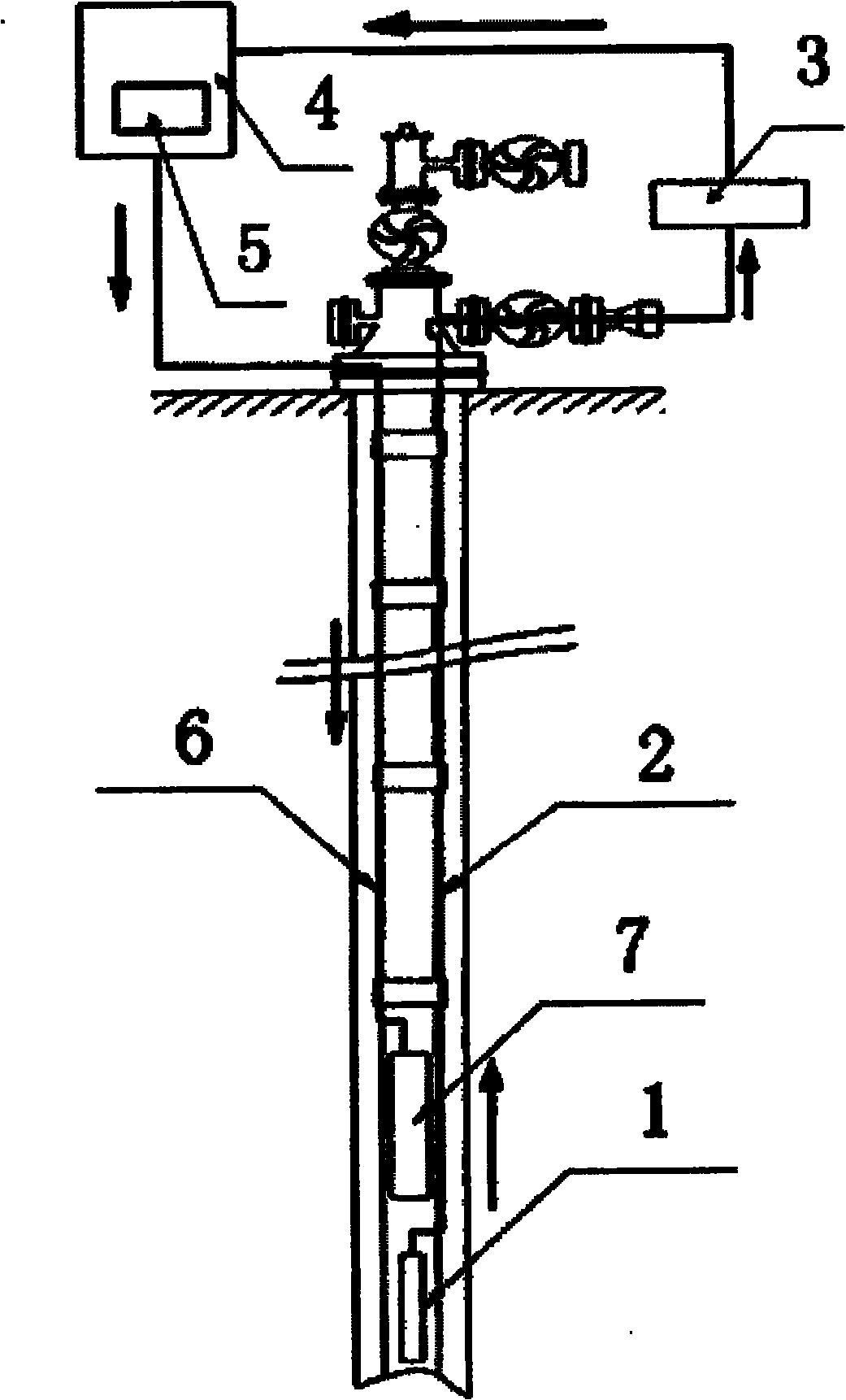

[0013] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further: figure 1 , which includes a downhole pressure sensor 1, a communication cable 2, a multifunctional acquisition instrument 3, a control cabinet 4, a power cable 6 and an electric submersible pump 7, and the output end of the downhole pressure sensor 1 is connected to the multifunctional acquisition instrument 3 through the communication cable 2 The input end is connected, the output end of the multi-function collector 3 is connected with the input end of the frequency converter 5 in the control cabinet 4, and the output end of the frequency converter 5 is connected with the input end of the electric submersible pump 7 through the power cable 6.

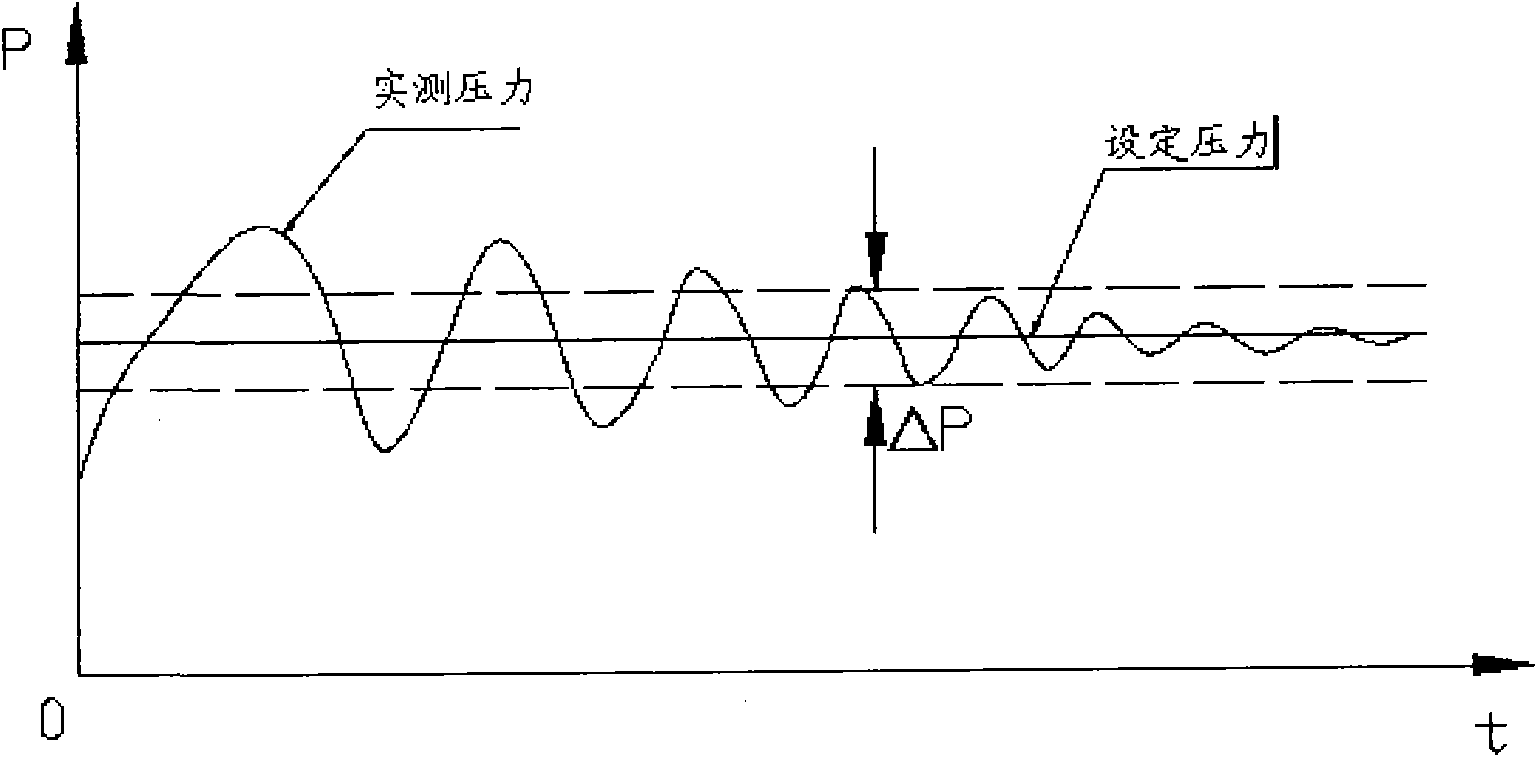

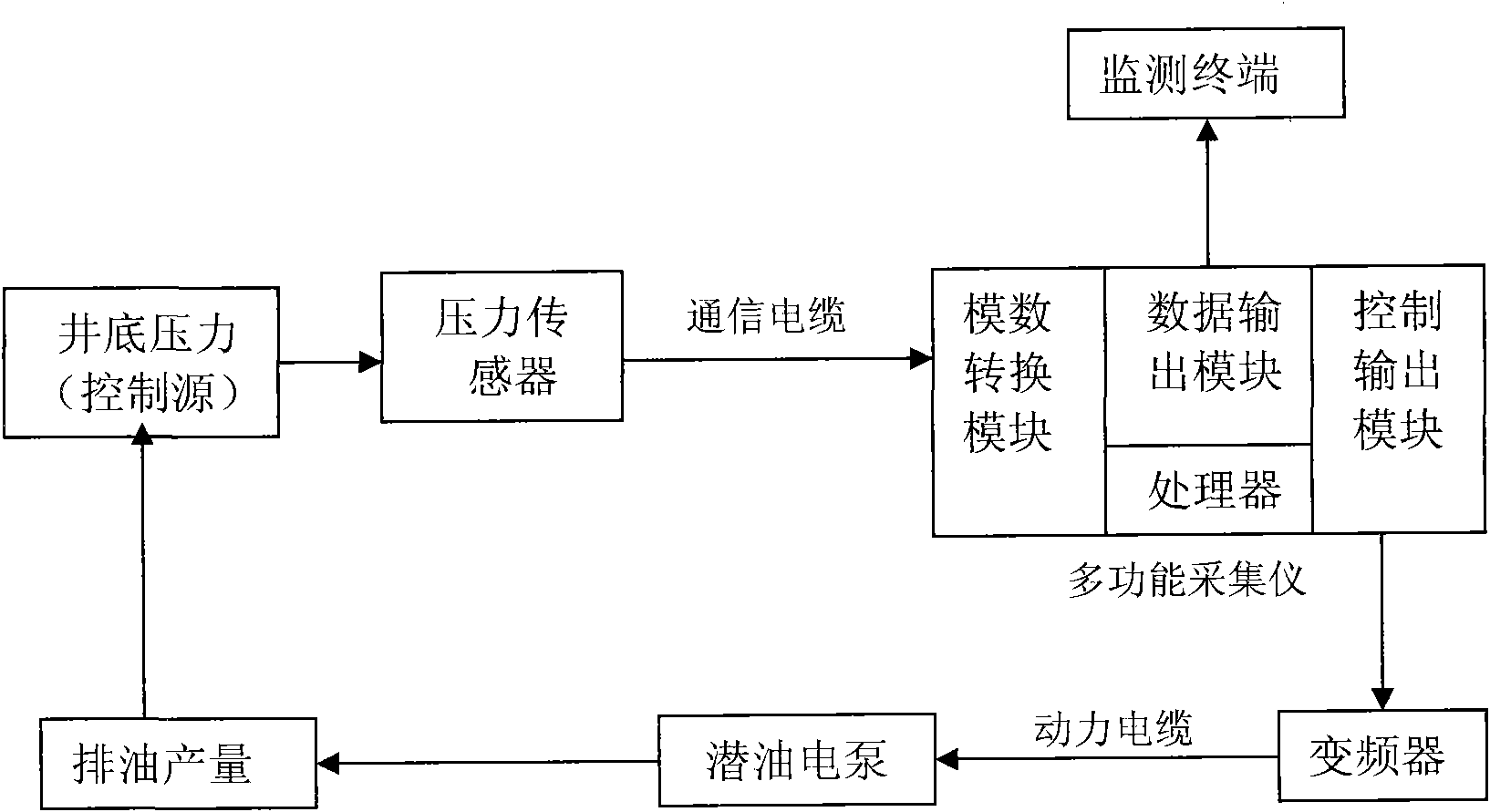

[0014] like image 3 As shown, since the bottom hole pressure directly reflects the oil production capacity of the oil well, the pressure is high and the production is large, so the bottom hole pressure is used as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com