Heat conductivity coefficient measurer of double-test-piece guarded hot plate for liquid nitrogen temperature area

A thermal conductivity measuring instrument technology, which is applied in the field of thermal conductivity measuring instrument with double specimen protective hot plate in the liquid nitrogen temperature zone, can solve the problems of unsuitable structure and characteristics, thermal conductivity measurement of thermal insulation materials, etc., to reduce liquid nitrogen evaporation, Effect of reducing measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

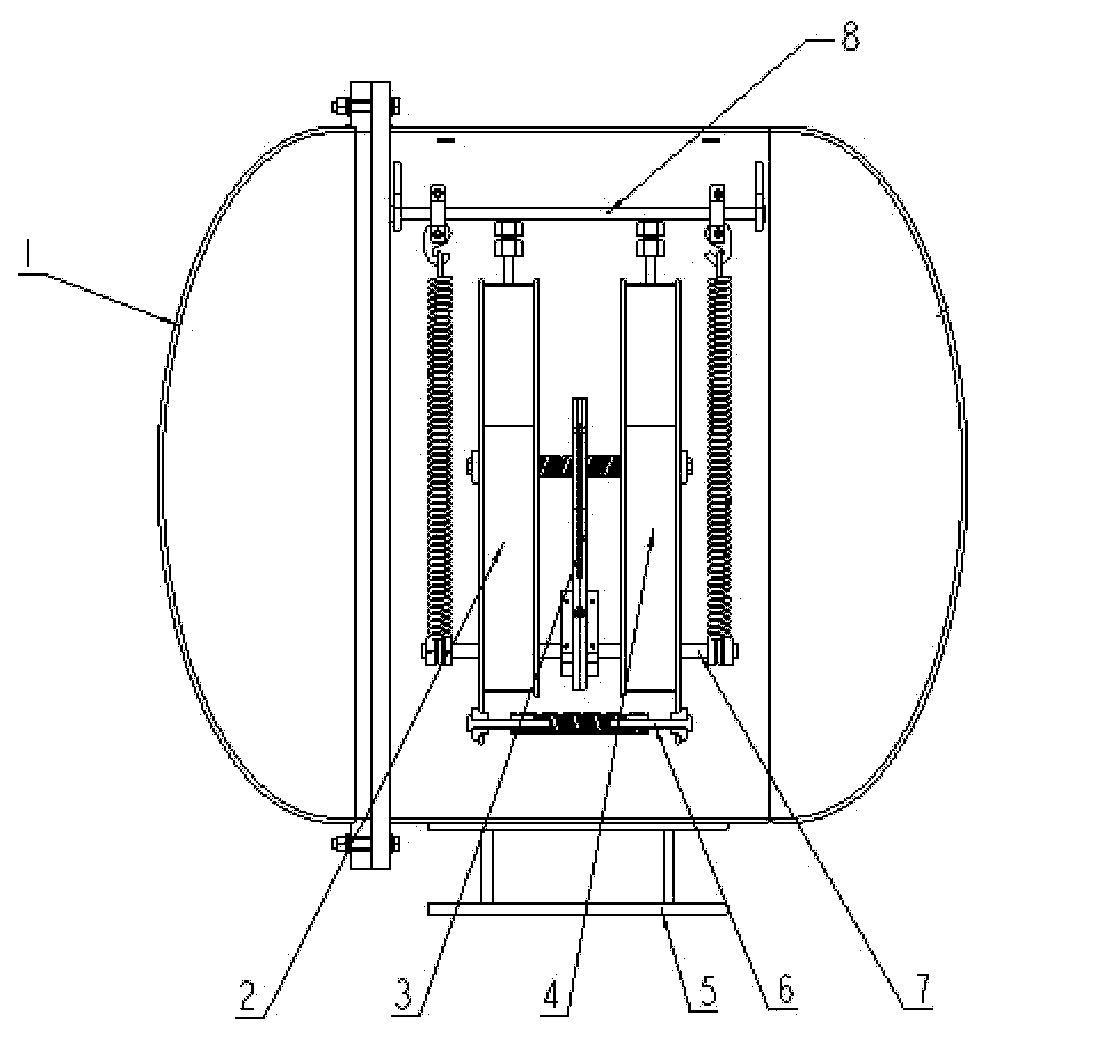

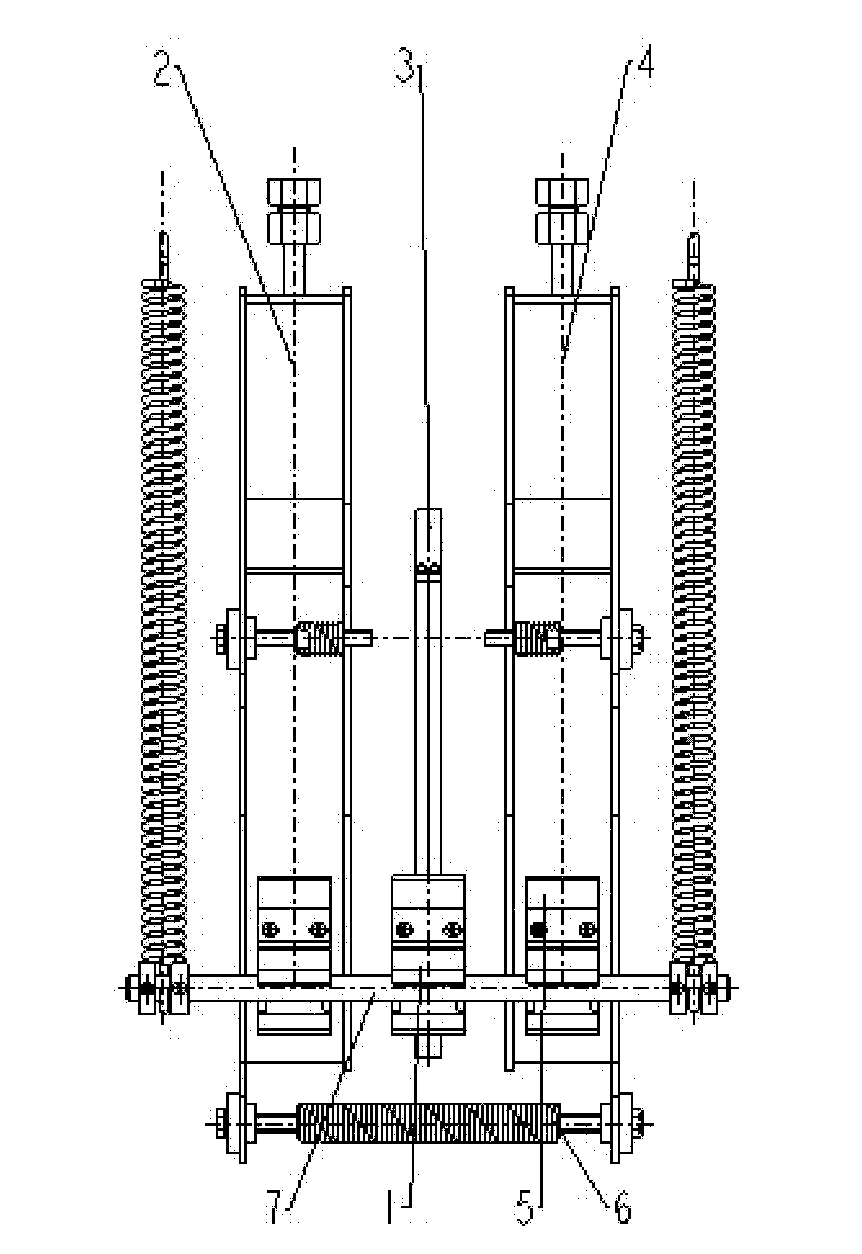

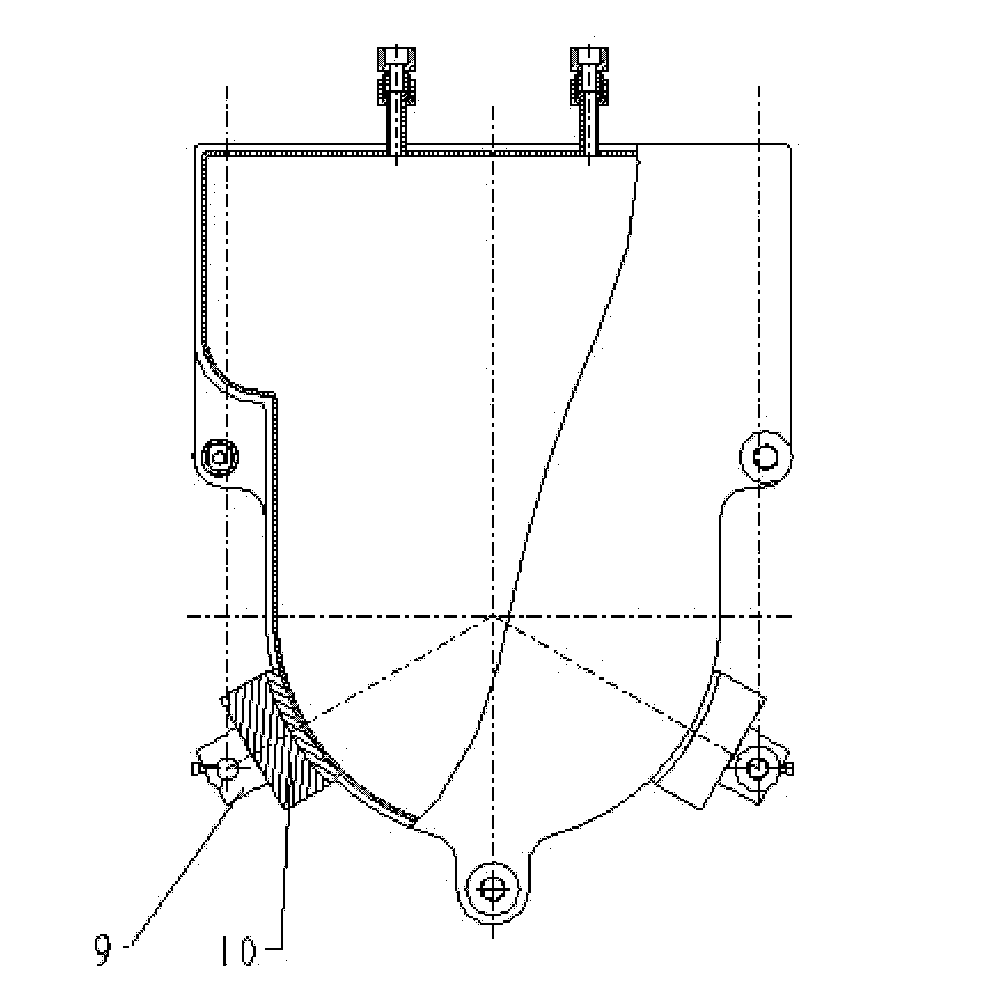

[0022] Such as figure 1 , figure 2 and image 3 As shown, this embodiment includes: a vacuum cover 1, a first liquid nitrogen container 2, a protective hot plate 3, a second liquid nitrogen container 4, two temperature sensors, a support plate 5, a sliding structure 7, a clamping structure 6 and hoisting Structure 8, wherein: the first test specimen is installed between the first liquid nitrogen container 2 and the protective hot plate 3, the second test specimen is installed between the second liquid nitrogen container 4 and the protective hot plate 3, and the protective hot plate 3 is located Between the two liquid nitrogen containers, one end of the clamping structure 6 is set on the first liquid nitrogen container 2, the other end of the clamping structure 6 is set on the second liquid nitrogen container 4, and the liquid nitrogen container and the protective hot plate 3 are fixed on On the sliding structure 7, the sliding structure 7 is connected with the hoisting stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com