Capacitance type sensor with liquid electrode for measuring liquid holdup of multiphase flow

A capacitive sensor, liquid holdup technology, applied in the direction of material capacitance, etc., can solve the problems of thick inner insulating cylinder, unable to use high temperature and high pressure multiphase flow measurement, increase the distance between the two plates of the capacitor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in more detail below in conjunction with the accompanying drawings.

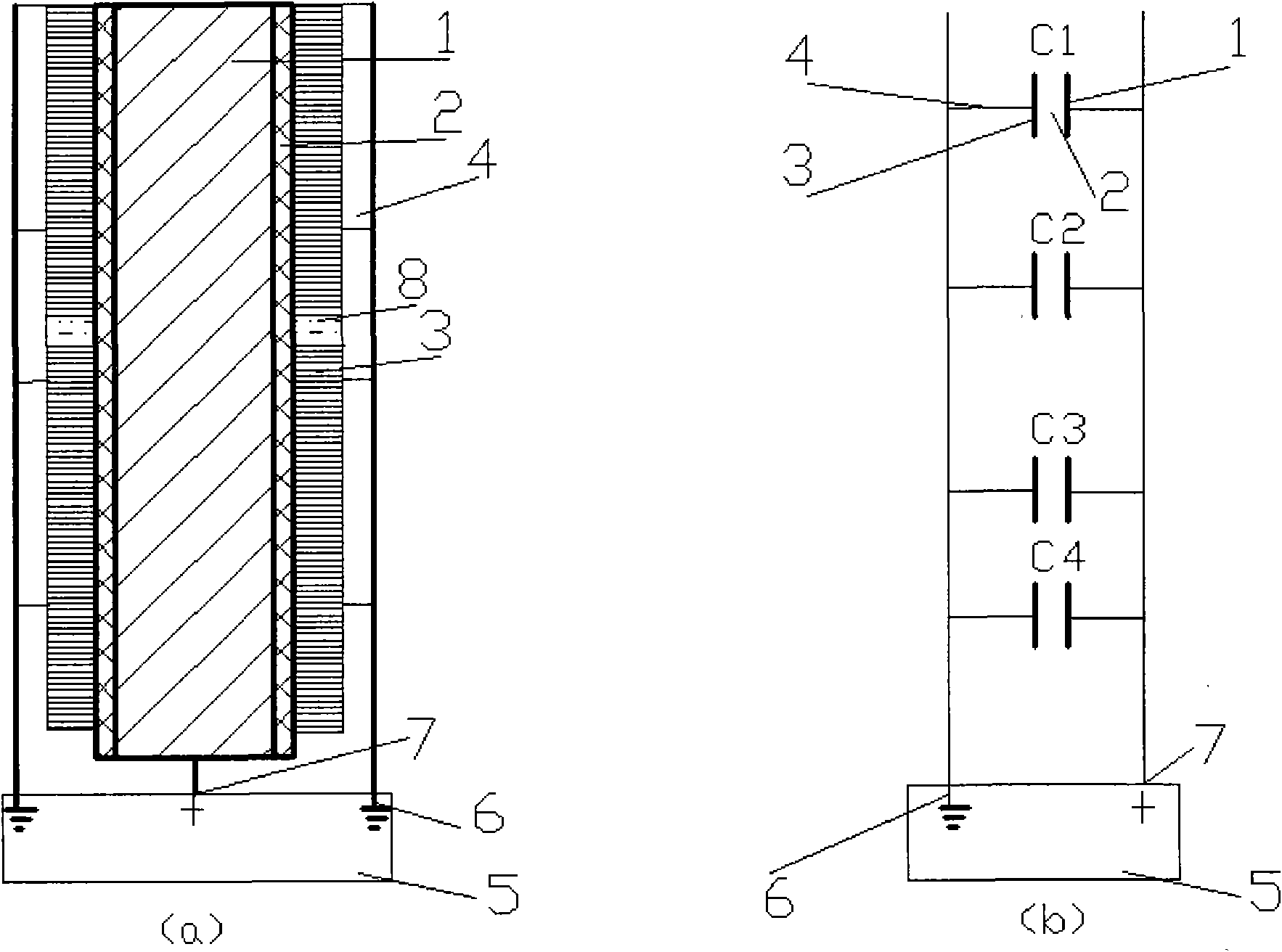

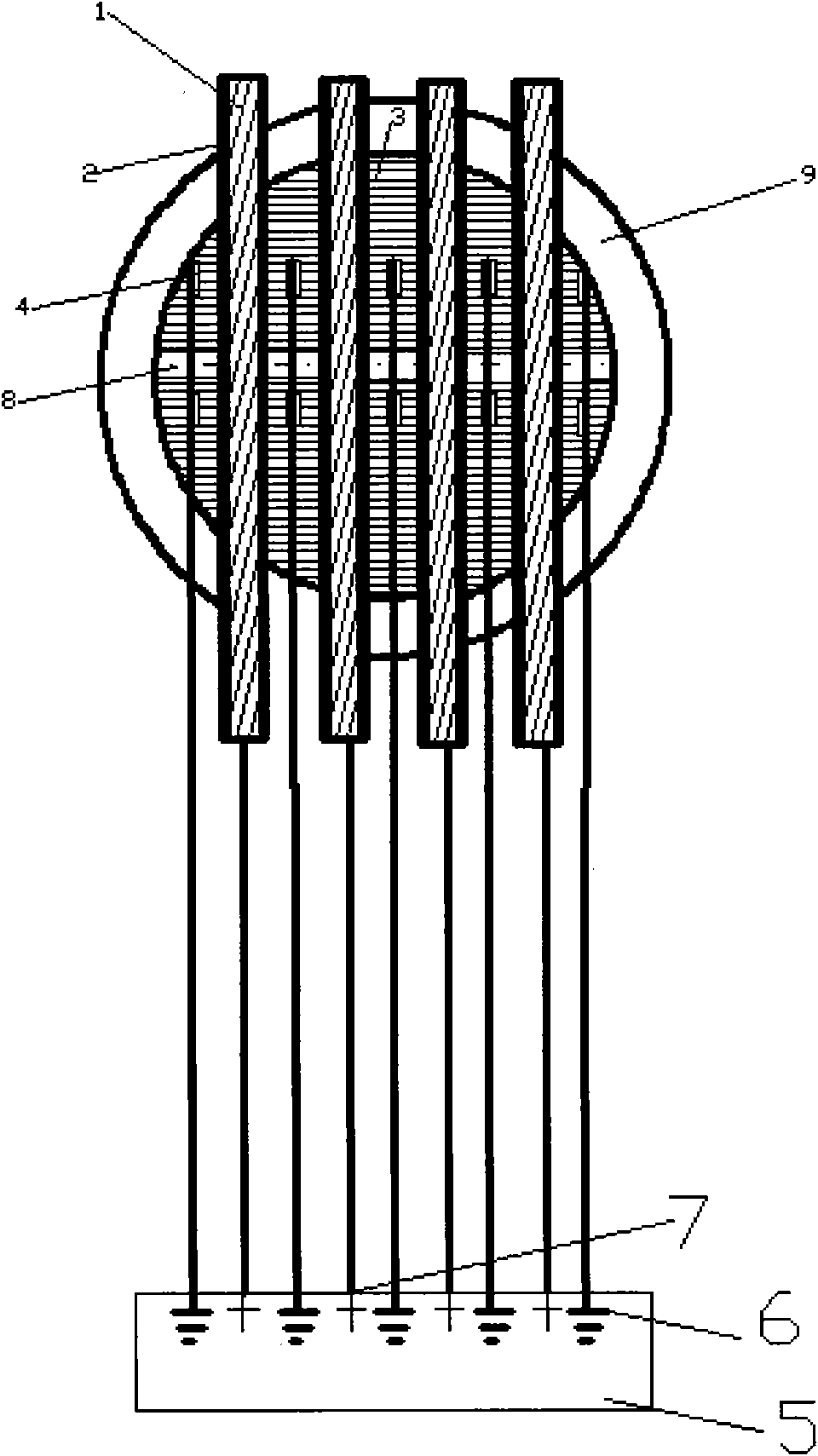

[0018] Such as figure 1 As shown, a metal plate 1 of a capacitive sensor with a liquid electrode for multiphase flow liquid holdup measurement is connected to a multiphase flow liquid holdup measurement circuit 5. The plate-like metal plate 1 has an insulating material Coating 2, the surface of the coating 2 of insulating material is in contact with the conductive liquid 3 and the non-conductive fluid 8 of the multi-phase flow to be measured, and the surface of the coating 2 of insulating material is arranged side by side with the metal plate 1 and More than one metal conductor 4 in contact with the conductive liquid 3, the metal conductor 4 is connected to the ground wire 6 of the multiphase flow liquid holdup measurement circuit 5, and the metal plate 1 is connected to the positive pole of the multiphase flow liquid holdup measurement circuit 5 7, the metal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com