Photolithography exposure device for implementing off-axis illumination by using free-form surface lens

A curved lens and exposure device technology, applied in the field of lithography, can solve the problems of increasing the complexity of lithography exposure devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

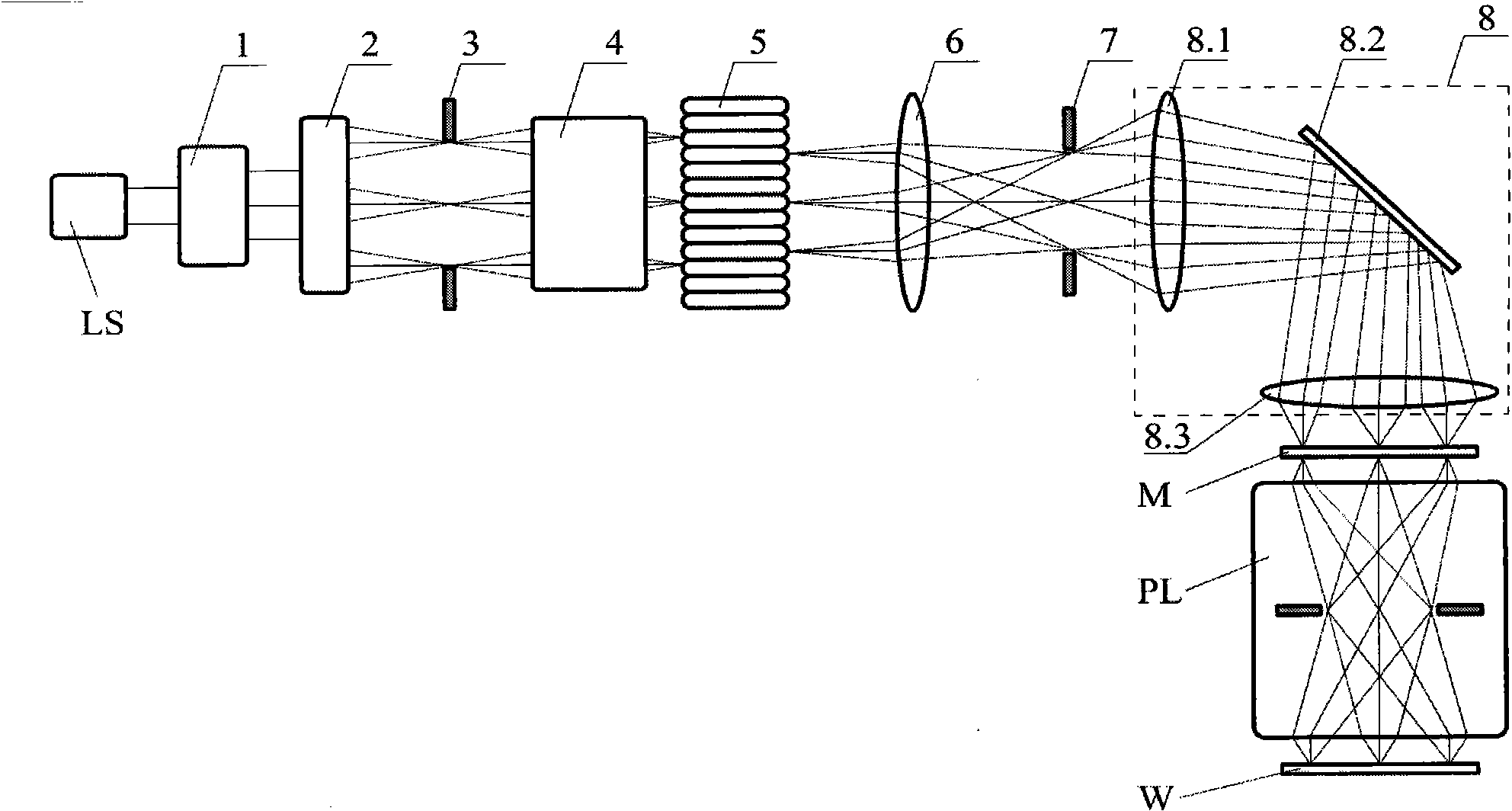

[0053] Such as figure 1 As shown, the lithography exposure device using a free-form surface lens to realize off-axis illumination includes a laser light source LS, a beam expander 1, a free-form surface lens beam shaper 2, a filter diaphragm 3, a zoom optical system 4, an optical integrator 5, Collimation optical system 6, field diaphragm 7, relay optical system 8, mask M, lithography projection objective lens PL, photoresist W; relay optical system 8 includes front lens group 8.1, intermediate mirror 8.2 and rear Lens group 8.3; the outgoing laser beam of the laser light source LS passes through the beam expander 1, the free-form surface lens beam shaper 2, the filter diaphragm 3, the zoom optical system 4, the optical integrator 5, the collimating optical system 6, the field of view Diaphragm 7, relay optical system 8, mask M, lithography projection objective lens PL, and finally irradiated to photoresist W; the position of filter diaphragm 3 and the position of the front su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com