Steel ball number detecting machine

A detection machine, steel ball technology, applied in the counting mechanism/item, counting objects, counting items shipped through a conveying device, etc., can solve the problems of missed detection or wrong detection, CV universal joint product flow to the bottom, etc., Achieve the effect of avoiding circulation, eliminating potential risks of automobiles, and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

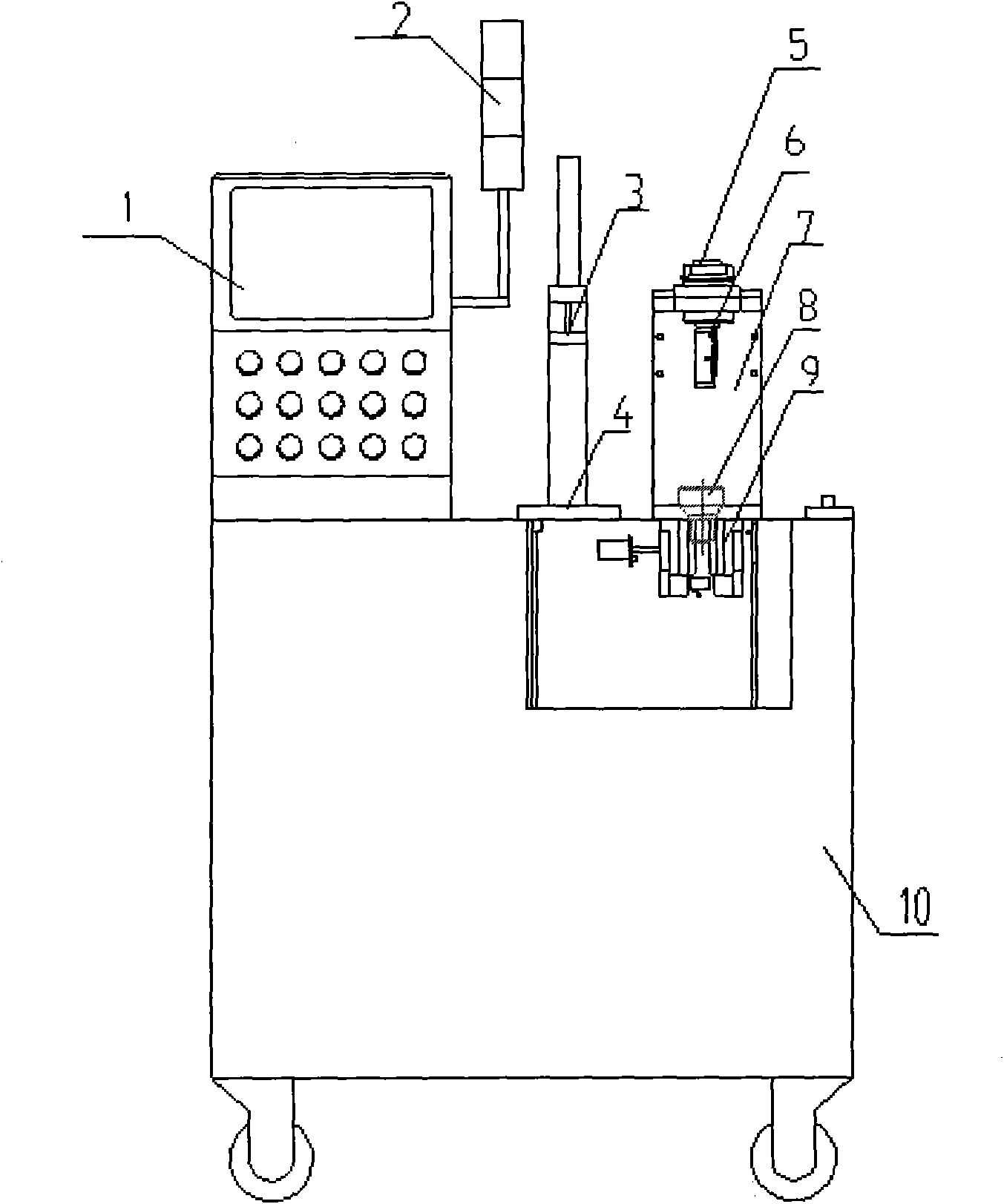

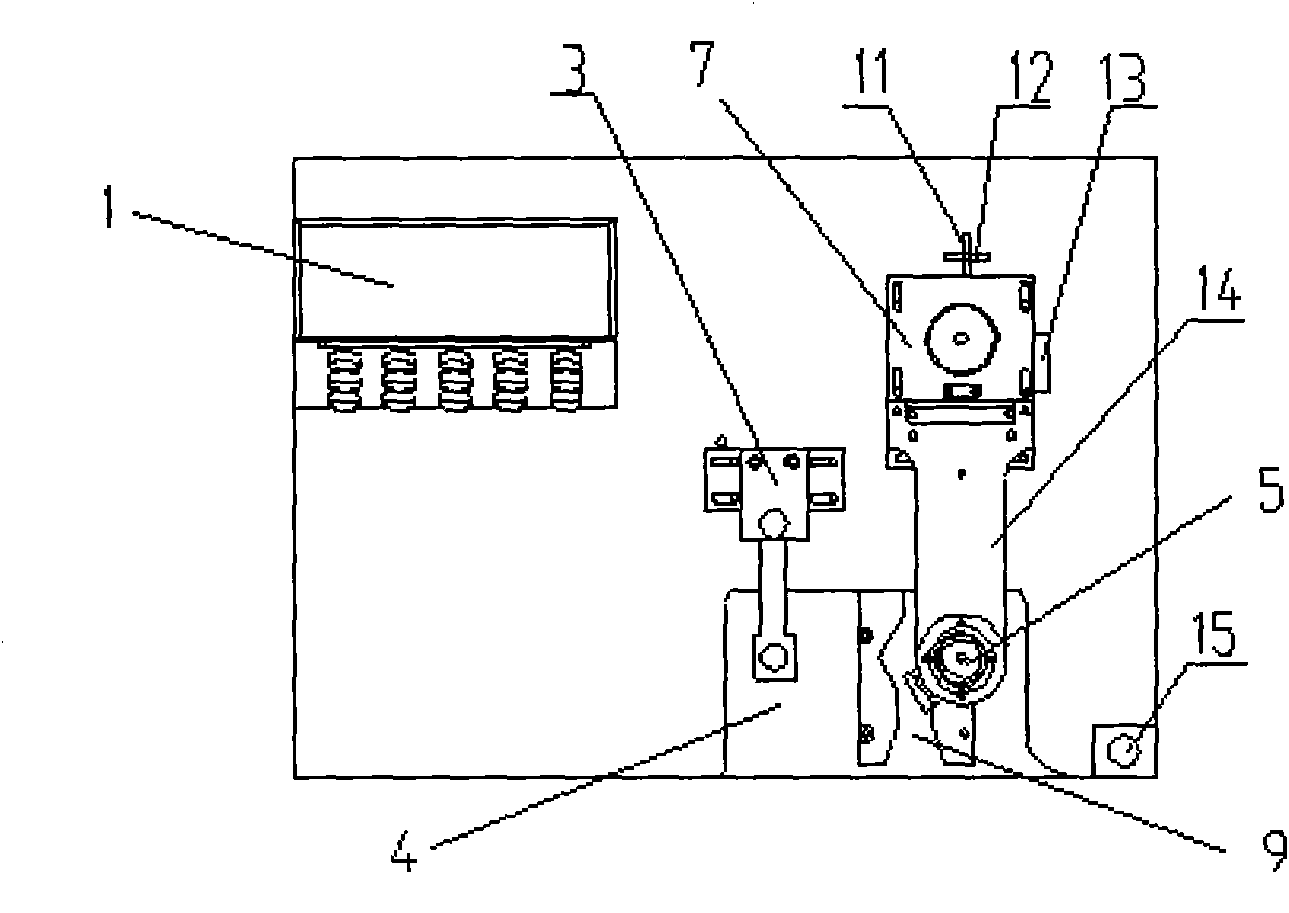

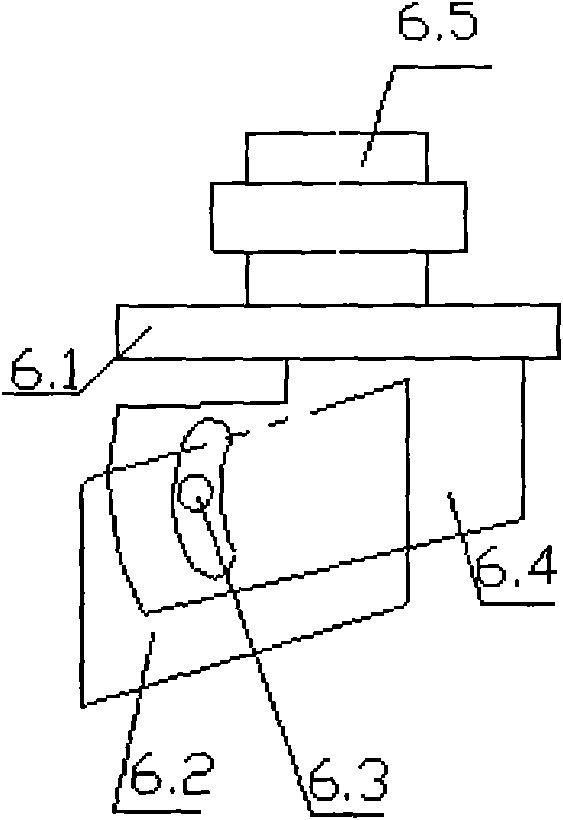

[0048] Such as Figure 1a , 1b As shown, a steel ball quantity detection machine according to the embodiment of the present invention includes a working surface, a base 7 , a laser sensor, an electric control mechanism, a rotating mechanism 5 , a feeding mechanism 9 and a sensor controller 13 . The base 7 is arranged on the working table of the body 10, the rotating mechanism 5 is fixed on the base 7, and the rotating mechanism 5 is connected with the laser sensor 6.2 (see figure 2 ), the feeding mechanism 9 is located at the laser sensor 6.2 (see figure 2 ); wherein, the feeding mechanism 9 is used to clamp or loosen the product containing the steel ball, the rotating mechanism 5 is used to drive the laser sensor to rotate in a ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com