Method for manufacturing TFT substrate for current control

A manufacturing method and current control technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as the inability to achieve high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

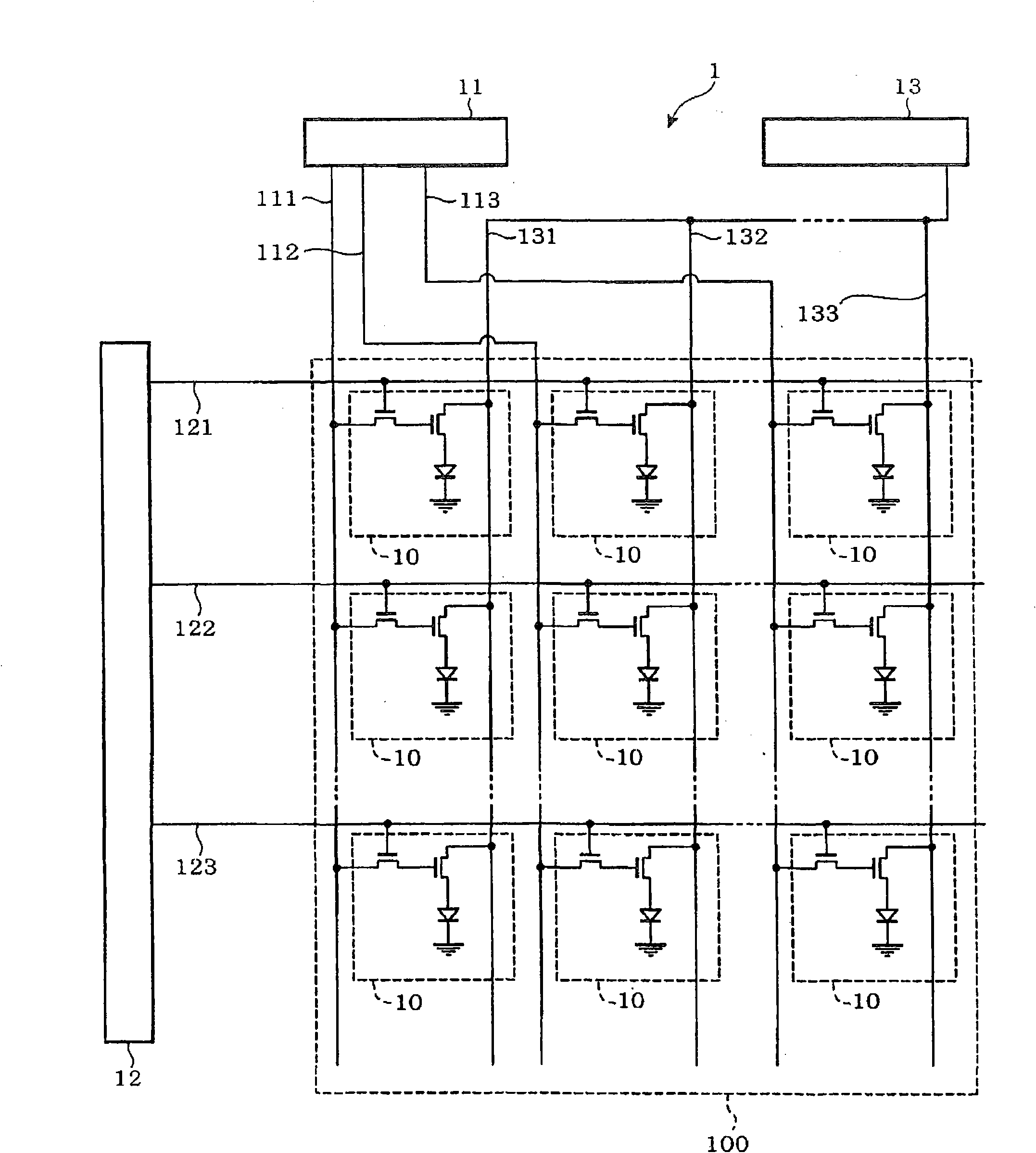

[0235] Figure 17 It is a block diagram showing the configuration of the organic EL display device according to the first embodiment of the present invention.

[0236] exist Figure 17Among them, the organic EL display device 1a as an electro-optical device includes a data line drive circuit 11, a scan line drive circuit 12, a power line control circuit 13a, a current measurement circuit 15, and a current control TFT substrate 100a (abbreviated as "TFT" as appropriate). substrate 100a"). In addition, m (column: m is a natural number)×n (row: n is a natural number) pixels 10 a are arranged in an array on the TFT substrate 100 .

[0237] The data line drive circuit 11 is connected to each pixel 10a through the first data line 111, the second data line 112...the mth data line 113 as a medium. The data line drive circuit 11 outputs a data signal to each pixel 10a.

[0238] In addition, the scanning line driving circuit 12 is connected to each pixel 10 a through the first scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com