Extraction method and apparatus of juice and/or puree, in particular from partially or completely frozen vegetables

一种果泥、果汁的技术,应用在果汁和果泥的提取,实现该方法的机器,果泥或果汁的提取效率领域,能够解决延迟酶促等问题,达到增强摩擦、高阻力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

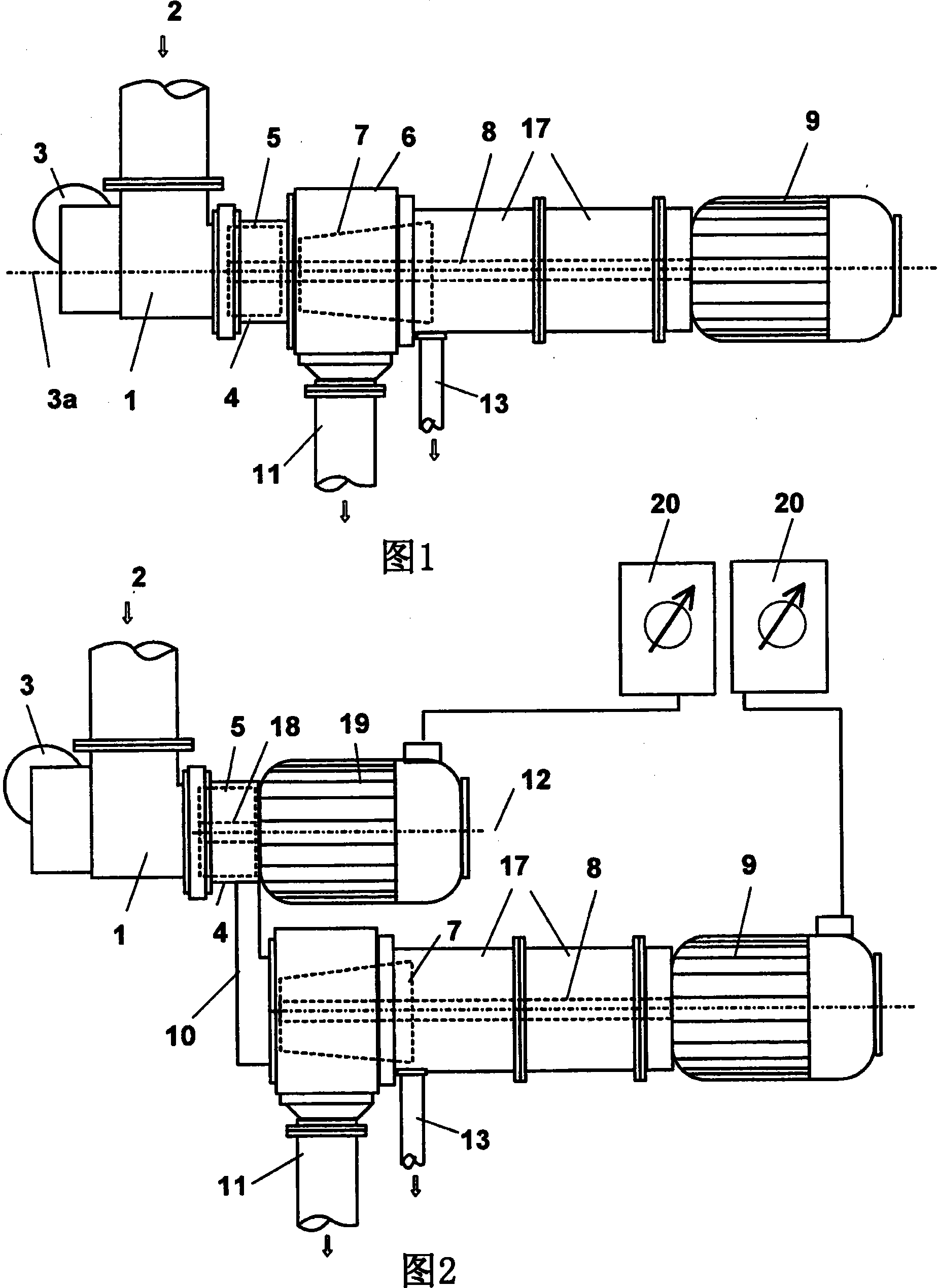

[0070] refer to figure 1 , a prior art rotary machine for the extraction of fruit purees or juices in food products of animal or vegetable origin at room temperature, operated along axis 3a by means of a motor 3, comprises an inlet pipe 1 at which is loaded, for example Animal food or plant food 2 of fruits or vegetables, and conveyed by a feed screw conveyor not shown.

[0071] According to the invention, in the frozen state, directly as IQF, or in the case of frozen products in drums, is loaded with a food slurry of the product 2 in pre-ground smaller portions, for example with dimensions set between 50-200 mm .

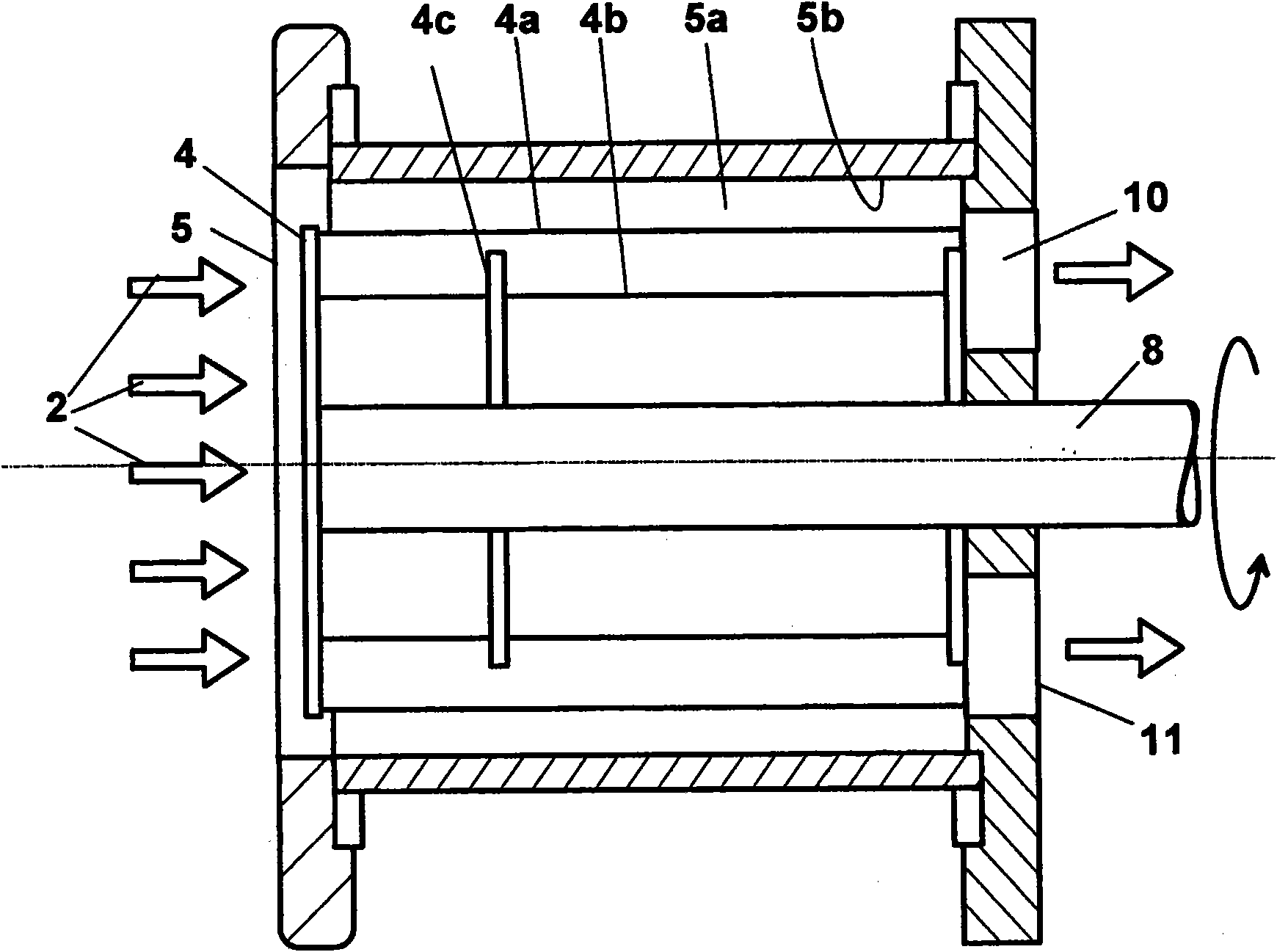

[0072] The frozen products then enter the softening section, where they are subjected to mechanical action until finely chopped frozen products are obtained, in particular with a size of less than 6 mm and a thawing rate of at least 10%.

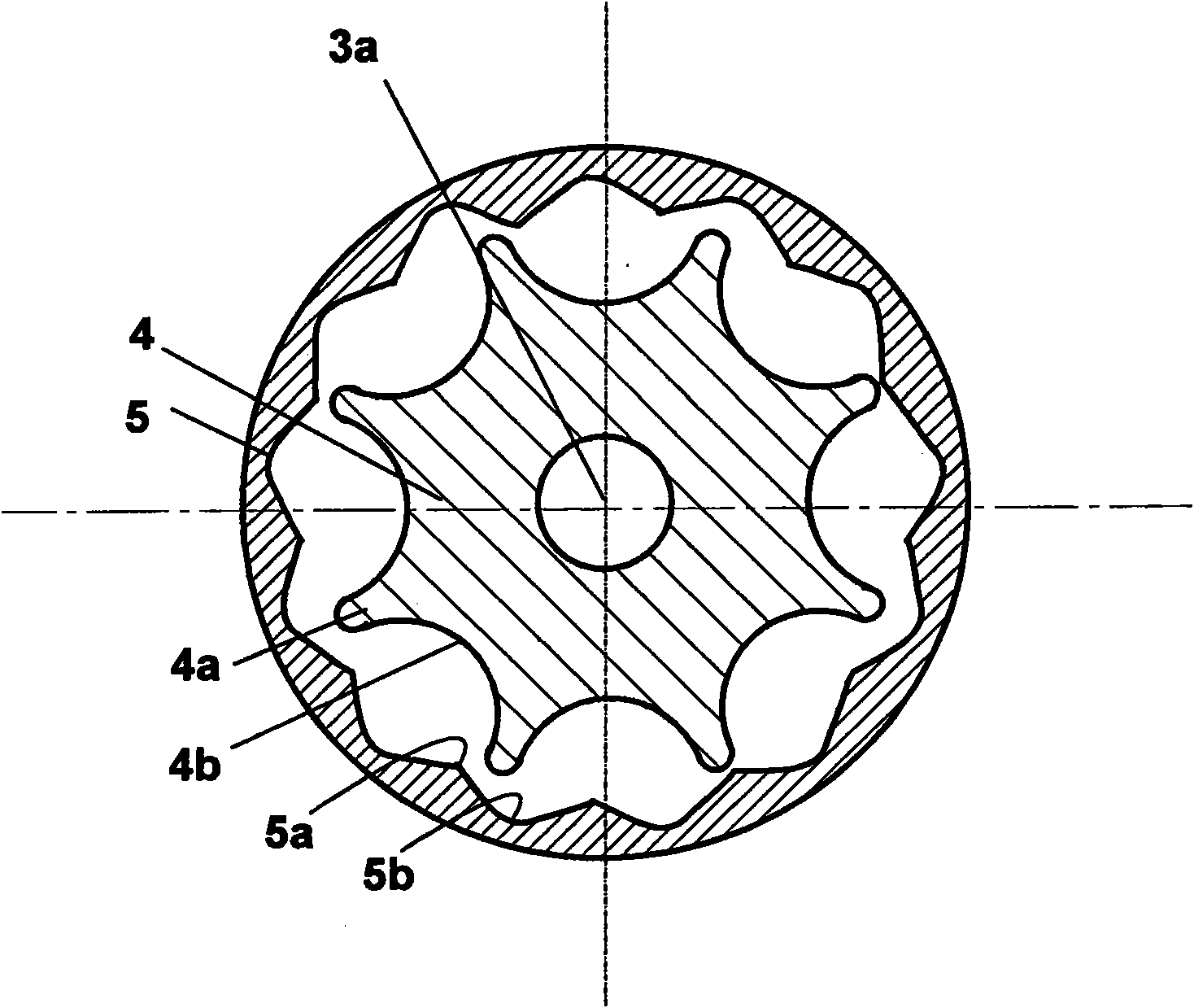

[0073] The softening part may include, for example, an armature 4 that is rotatable at high speed in a stator 5 . In this se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com