Linkage type horizontal planar motion mechanism

A planar motion mechanism and horizontal plane technology, which is applied in transportation and packaging, ship parts, ships, etc., can solve the problems of large hydraulic drive volume, high sealing requirements, easy to pollute pools, etc., to achieve convenient control and strong resistance to harsh environments , the effect of short vertical distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

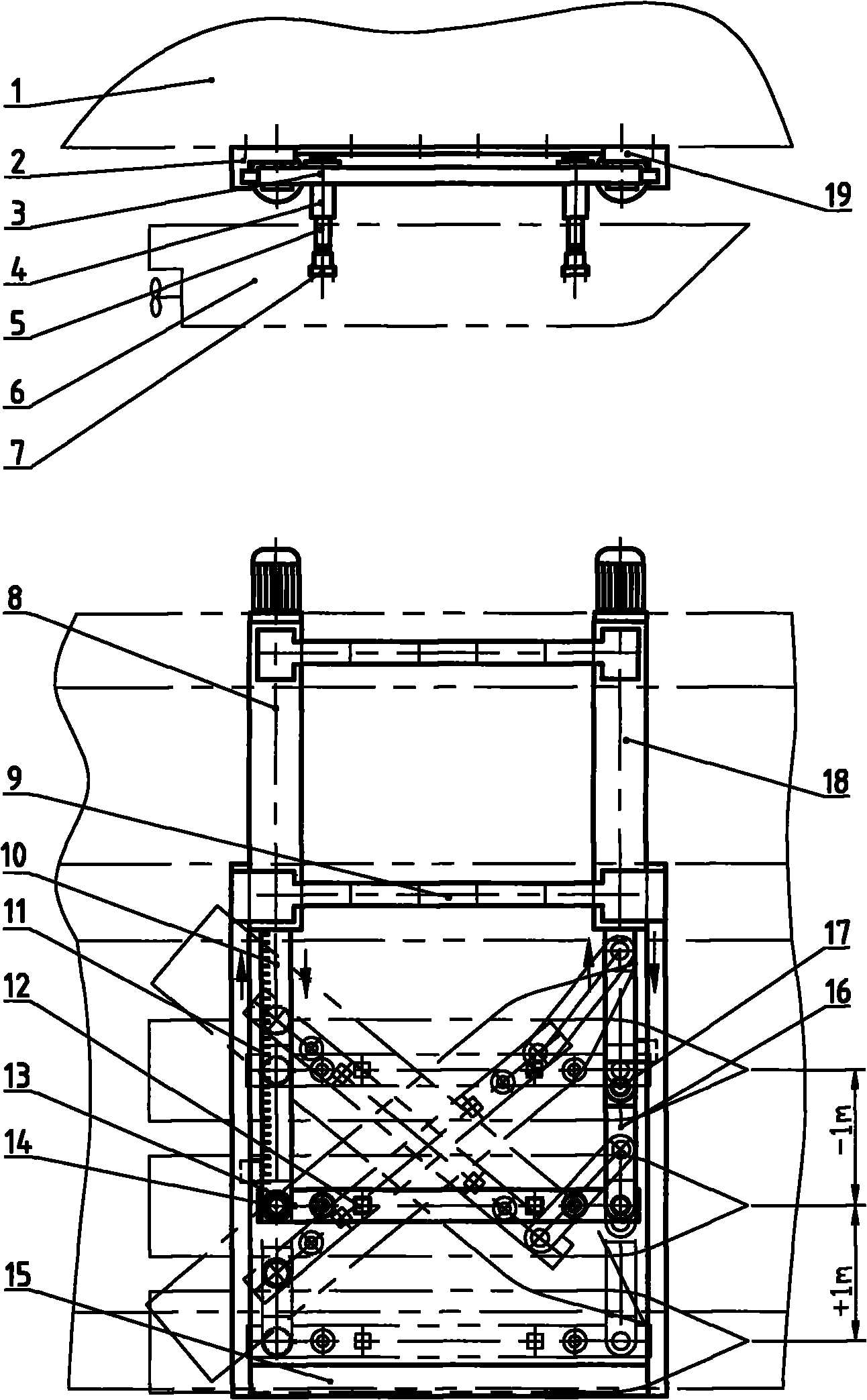

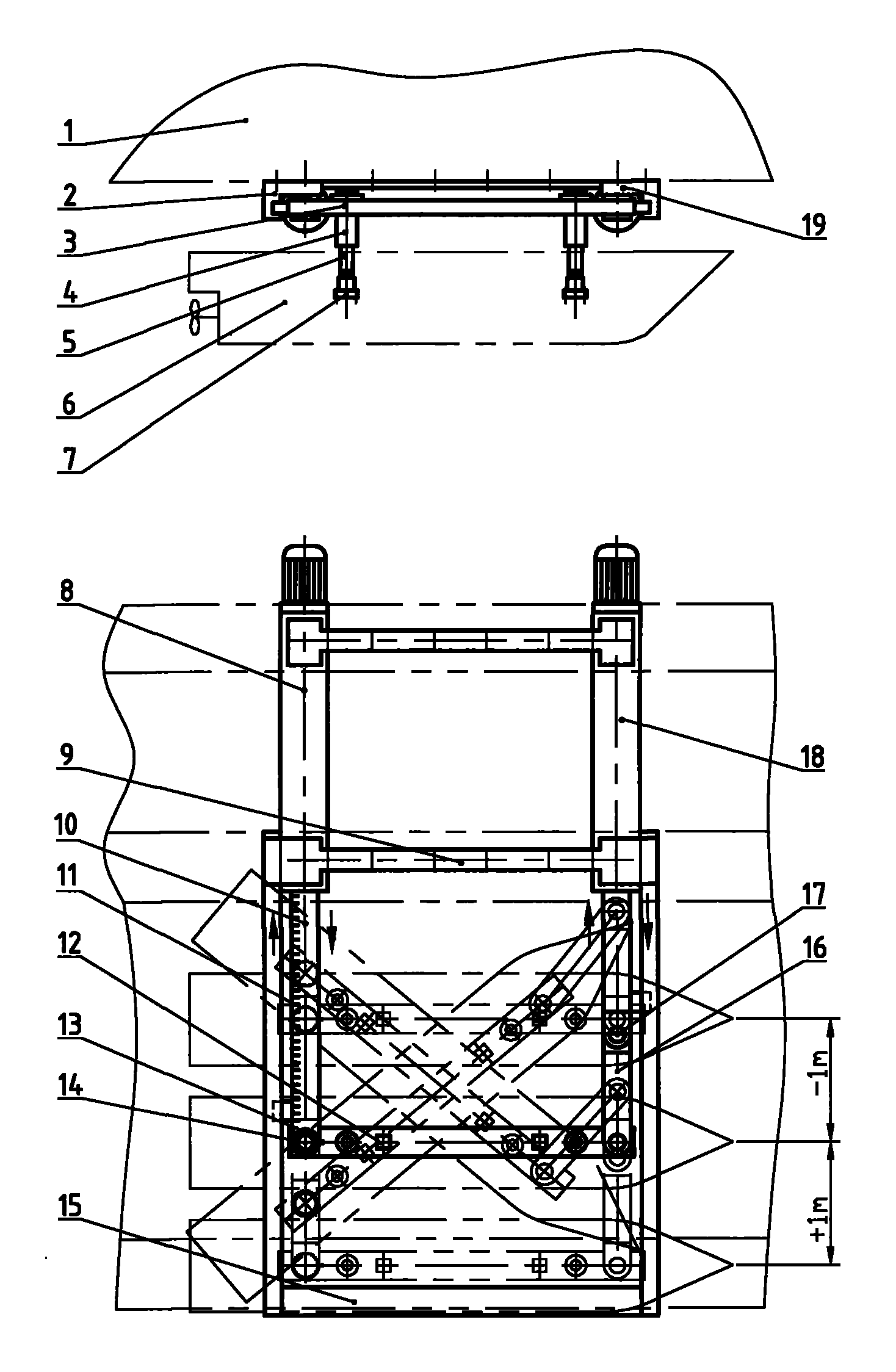

[0013] The link-type planar motion mechanism of the present invention will be further described below in conjunction with the drawings and specific embodiments.

[0014] Such as figure 1 Shown, the pool ship model test of the present invention uses the connecting rod type horizontal plane motion mechanism, including the support frame 2,19 fixed with the pool ship model trailer 1, the mounting frame 9 and the two servo electric cylinders 18,8 used for fixing the front and rear 15, the beam 3 is flexibly connected with the push rod 10 and the connecting rod 16 through the rotary joint 17. The connecting rod installation hole 12 on the beam 3 is fixed with the front and rear connecting rods 4, the connecting rod 4 and the adjusting rod 5 automatically adjust the length of the front and rear connecting rods through the linear bearing, and the force measuring balance 7 is connected with the ship model 6 and the adjusting rod 5 to form a connecting rod type Horizontal plane motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com