Method for monitoring corrosion depth of silicon in real time

A corrosion depth, real-time monitoring technology, applied to the process, coating, microstructure device, etc. used to produce decorative surface effects, can solve problems such as difficulty in corrosion depth, corrosion uniformity deviation, corrosion rate fluctuations, etc., to achieve reduction Adverse effects, small effects of process complexity, effects of simplification of tools and operating steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

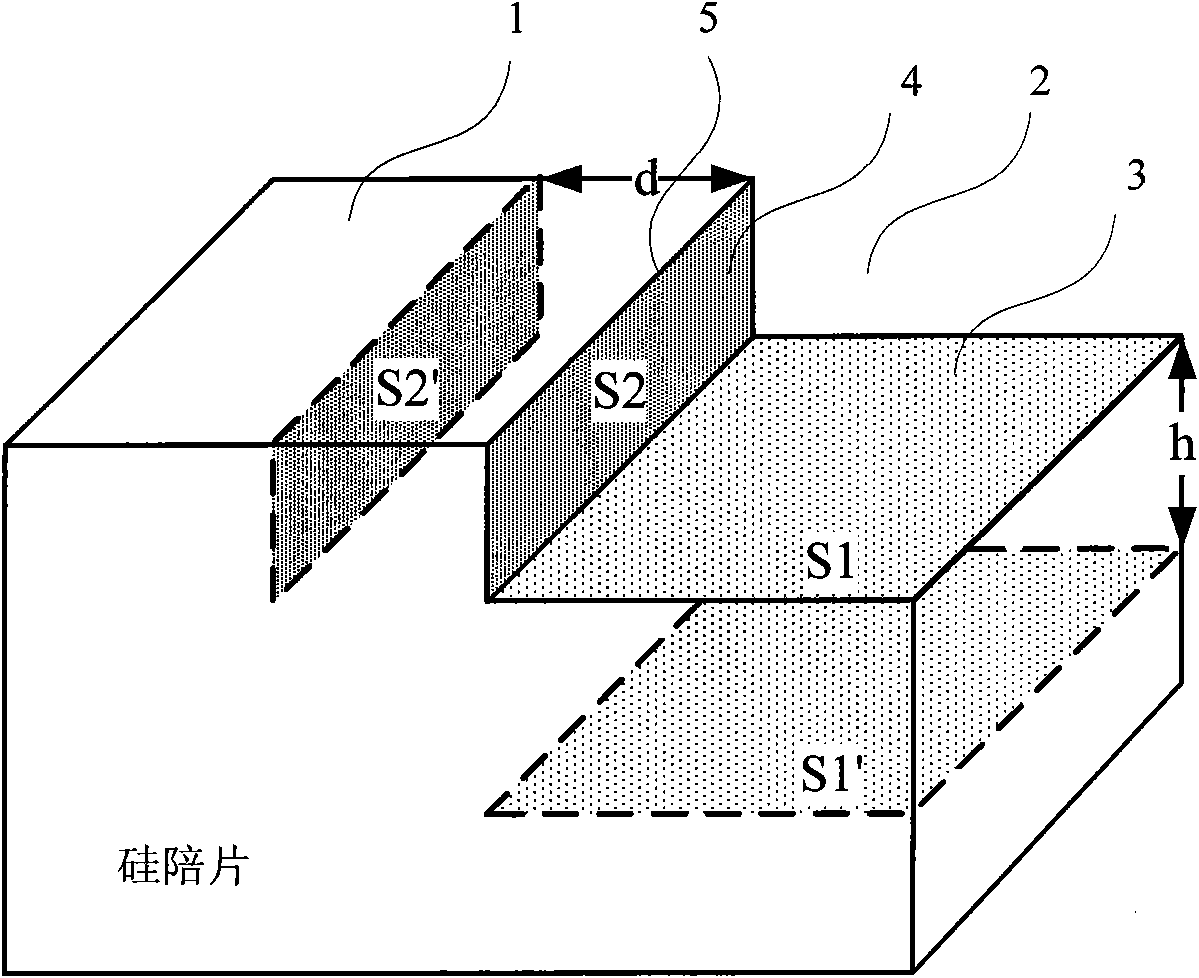

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0031] The embodiment of the present invention uses a pre-patterned companion to monitor the KOH etching depth of silicon, including the following steps:

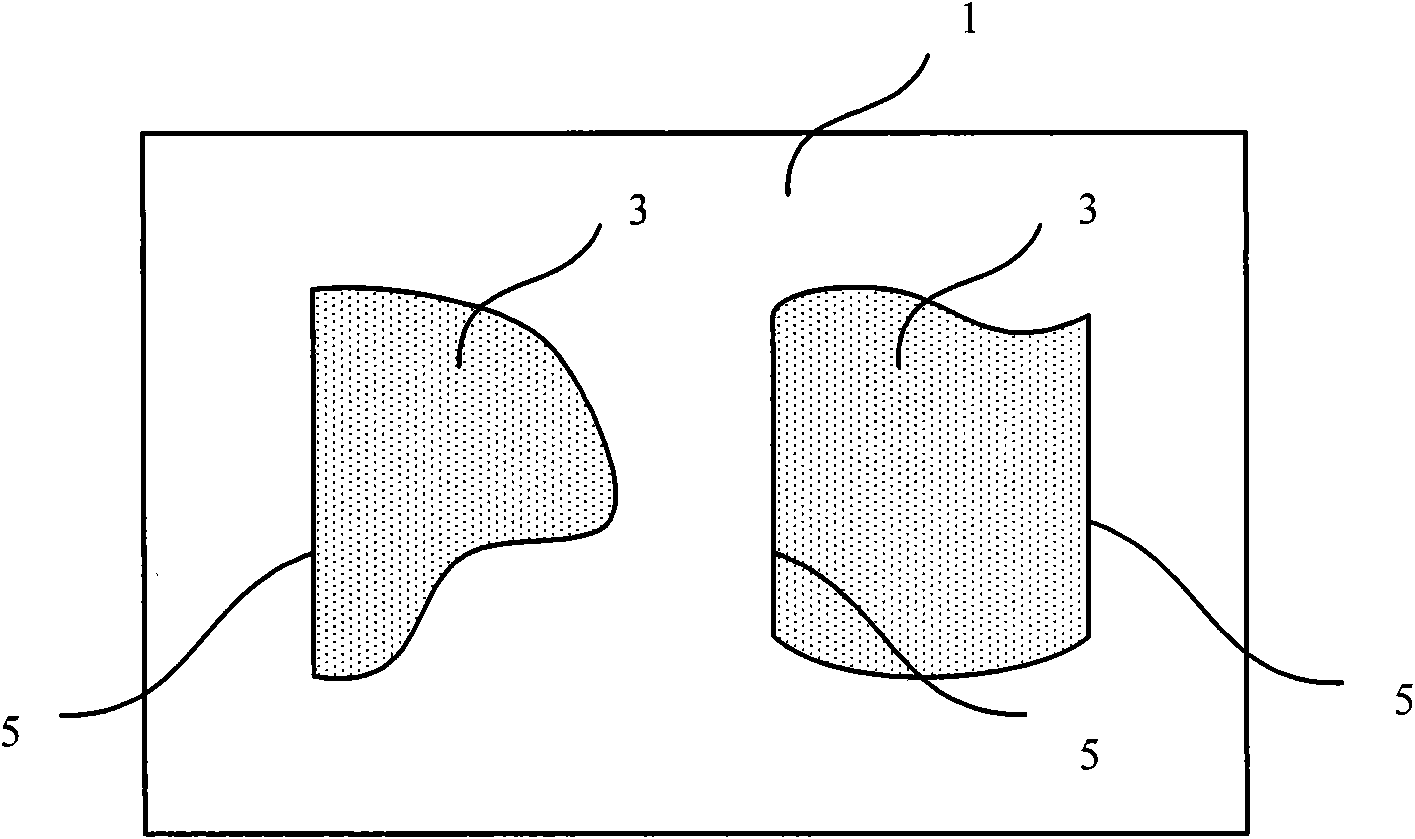

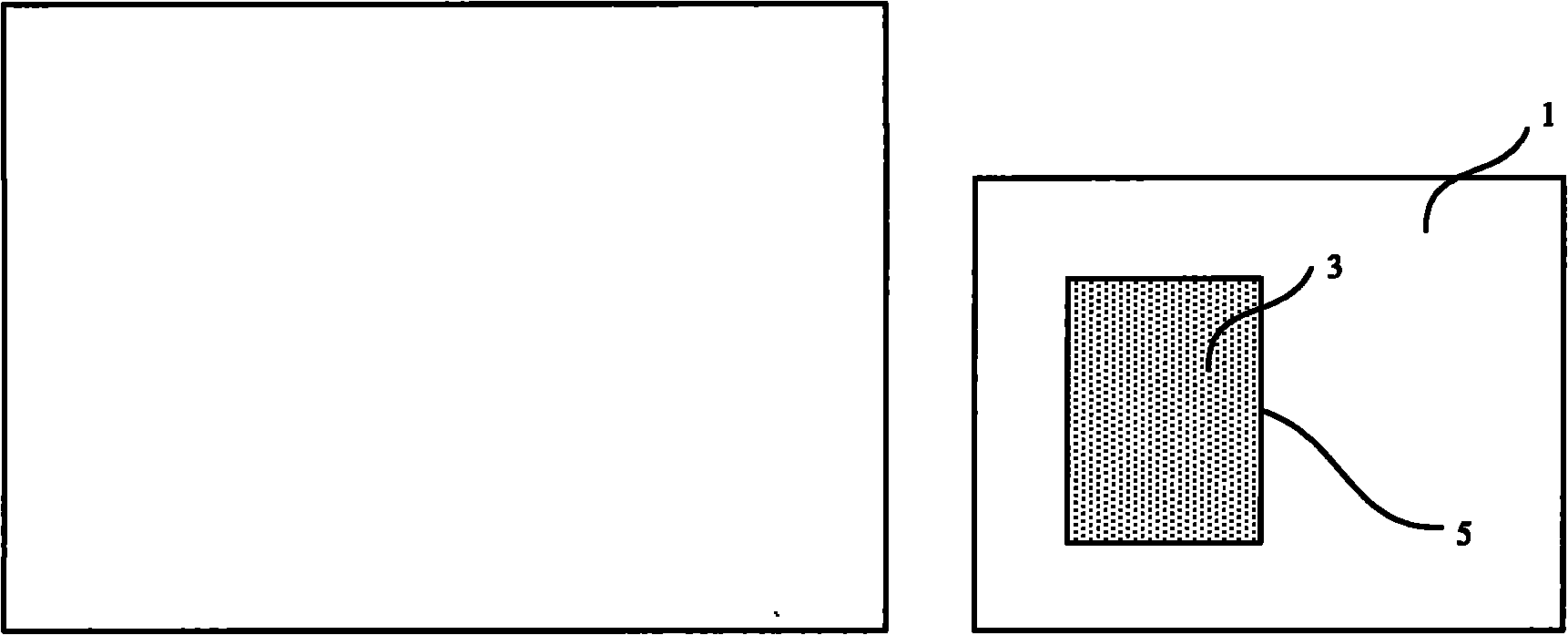

[0032] 1. Grow a certain thickness of silicon oxide layer and silicon nitride layer on the substrate silicon substrate, and then carry out reactive ion etching to obtain the required corrosion depth monitoring pattern such as Figure 5 shown. A companion piece comprises four corrosion grooves 2 on its surface 1, and each corrosion groove 2 comprises four flanges 6, and each flange 6 comprises two monitoring surfaces 4 respectively, so each corrosion groove 2 comprises Eight monitoring lines 5. By designing the pattern of the mask, the Figure 5 A total of 16 flanges are shown made of the following widths (in microns): 100, 110, . . . , 250.

[0033] The substrate used for the companion fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com