Alpha-shaped material returning valve

A return valve and spiral tube technology, applied in the field of α-type return valve, can solve the problems of dead zone, material adhesion, small resistance, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An α-type return valve includes a spiral pipe, a side air supply pipe, a return riser flange and an inclined pipe flange. The spiral pipe is α-shaped, one end is connected to the vertical standpipe through the flange of the return riser pipe, and the other end is connected to the return inclined pipe through the inclined pipe flange. The included angle is set, the angle between the return inclined pipe and the horizontal direction is 40°, the rotation angle of the spiral pipe is made 310°, the bottom of the spiral pipe is provided with a side air supply pipe, and the axis of the side air supply pipe is tangent to the spiral pipe The centerline, side air ducts are parallel to the horizontal direction. Due to the low viscosity of the material flowing through the spiral tube, the diameter of the selected spiral tube is small, and the circulation volume of the material does not need to be too large. The length ratio of the diameter of the spiral tube to the radius of curvat...

Embodiment 2

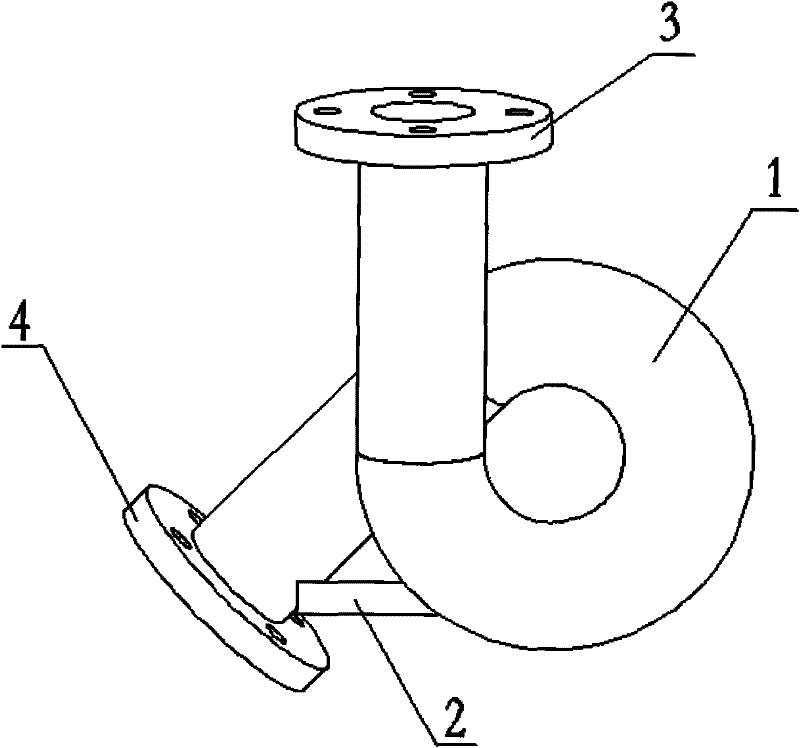

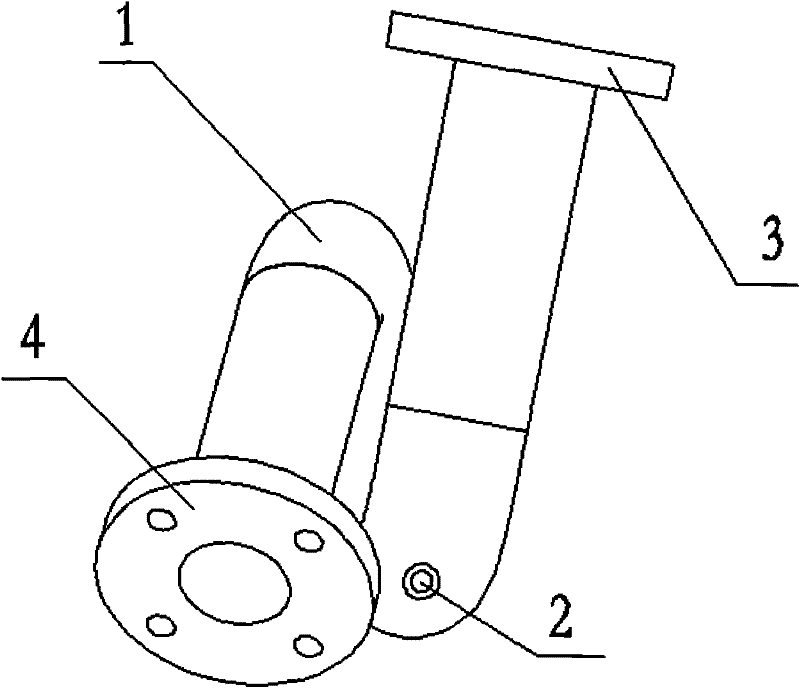

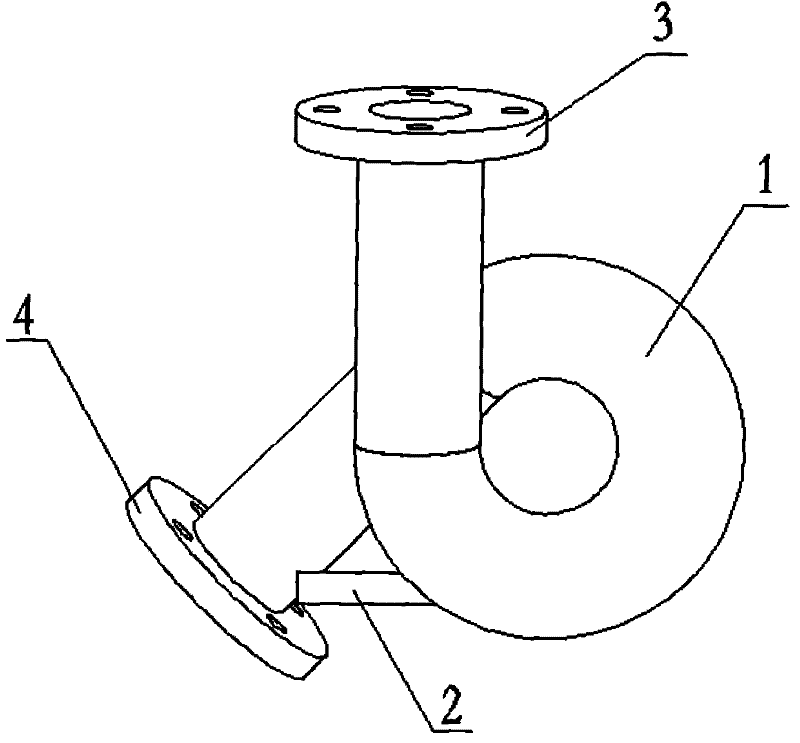

[0020] Such as Figure 1-2 As shown, an α-type return valve includes a spiral pipe 1 , a side air supply pipe 2 , a return standpipe flange 3 and an inclined pipe flange 4 . The helical pipe 1 is α-shaped, one end is connected to the vertical standpipe through the return riser flange 3, and the other end is connected to the return inclined pipe through the inclined pipe flange 4. The rotation angle of the spiral pipe is according to the return inclined pipe and the vertical pipe. The angle in the horizontal direction is set, the angle between the inclined return pipe and the horizontal direction is 45°, the rotation angle of the spiral pipe 1 is made 320°, and the bottom of the spiral pipe 1 is provided with a side air supply pipe 2 and a side air supply pipe 2 The axis is tangent to the center line of the spiral tube 1, and the side air supply tube 2 is parallel to the horizontal direction. Due to the low viscosity of the material flowing through the spiral tube, the diamete...

Embodiment 3

[0023] An α-type return valve includes a spiral pipe, a side air supply pipe, a return riser flange and an inclined pipe flange. The spiral pipe is α-shaped, one end is connected to the vertical standpipe through the flange of the return riser pipe, and the other end is connected to the return inclined pipe through the inclined pipe flange. The included angle is set, the angle between the return inclined pipe and the horizontal direction is 60°, the rotation angle of the spiral pipe is made 330°, the bottom of the spiral pipe is provided with a side air supply pipe, and the axis of the side air supply pipe is tangent to the spiral pipe The angle between the center line and the side air supply pipe and the horizontal direction is 45°. Due to the high viscosity of the material flowing through the spiral tube, the diameter of the selected spiral tube is larger, and the circulation volume of the material is larger. The length ratio of the diameter of the spiral tube to the radius ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com