Fire grate structure of coal-fired boiler

A technology for coal-fired boilers and grates, which is applied in the direction of grates, combustion methods, and combustion equipment. Small heat loss, reasonable heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

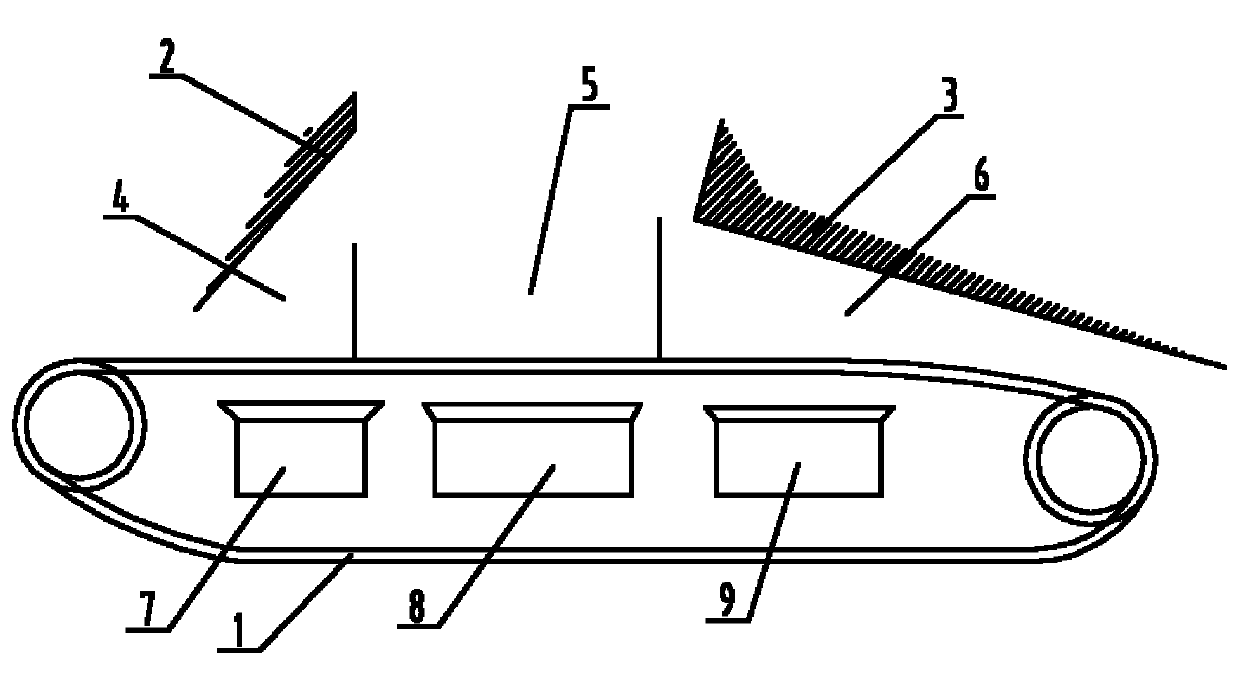

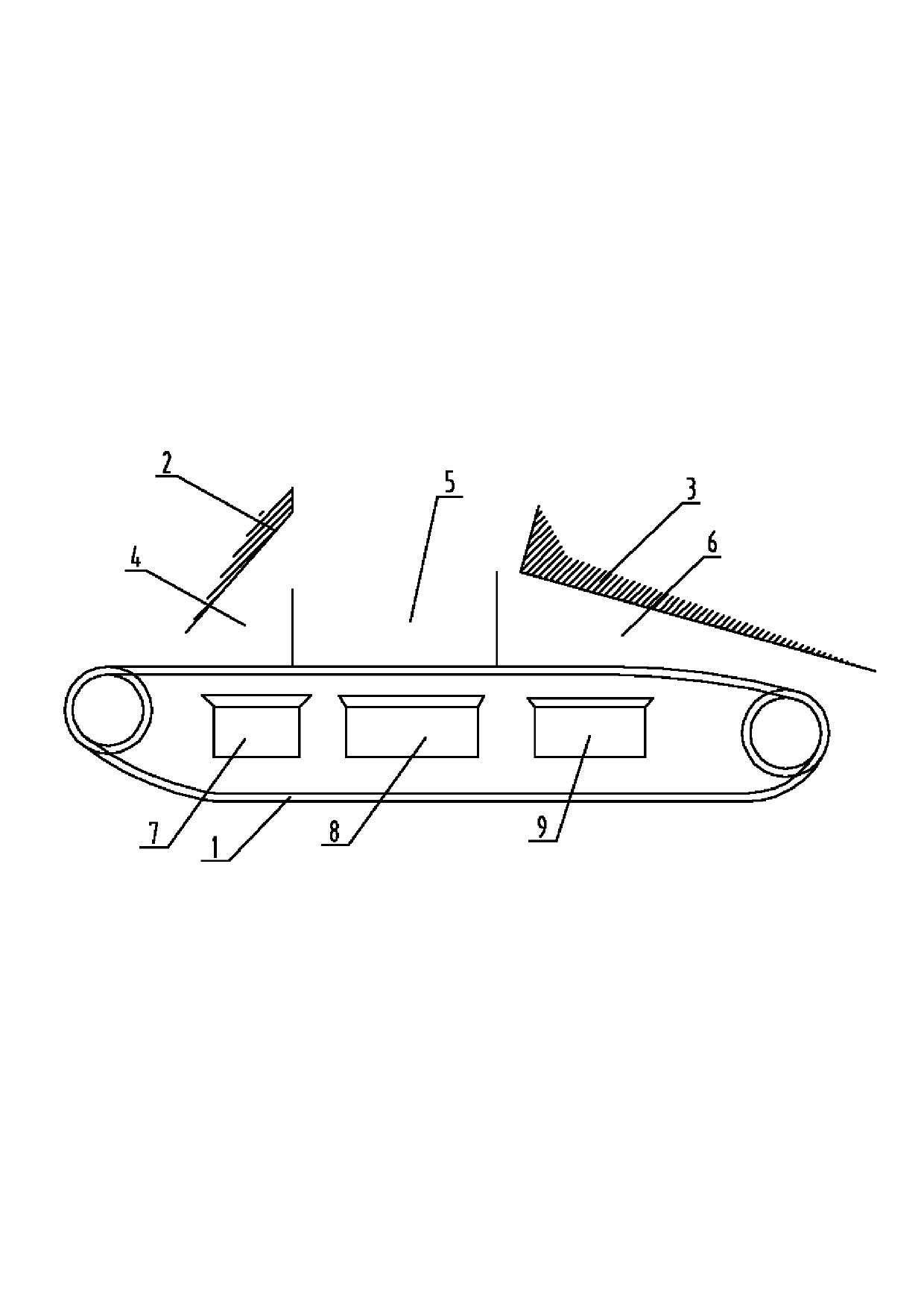

[0008] See figure 1 , which includes a fire grate 1, a front arch 2 is arranged above the front section of the fire grate 1, and a rear arch 3 is arranged on the rear section. The fire grate includes an ignition area 4, a combustion area 5, and a burnout area 6. A high-temperature hot air device 7 is installed below the 4, a low-temperature cold air device 8 is installed below the combustion zone 5 of the fire grate, and a high-temperature hot air device 9 is installed below the burnout zone 6 of the fire grate. The air outlets of the high-temperature hot air devices 7 and 9 face the ignition zone 4 and the burnout area 6 respectively, and the air outlets of the low-temperature cold air device 8 face the combustion zone 5 .

[0009] Its working principle is as follows: the ignition point of coal is high, and the flame radiation is relatively weak, introducing high-temperature hot air in the ignition zone 4 can shorten the preheating time, allowing the volatilization of the coa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap