Method and system for calibrating laser scanner

A laser scanner, scanner technology, applied in radio wave measurement systems, instruments, etc., can solve the problems of large manual workload and difficult actual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

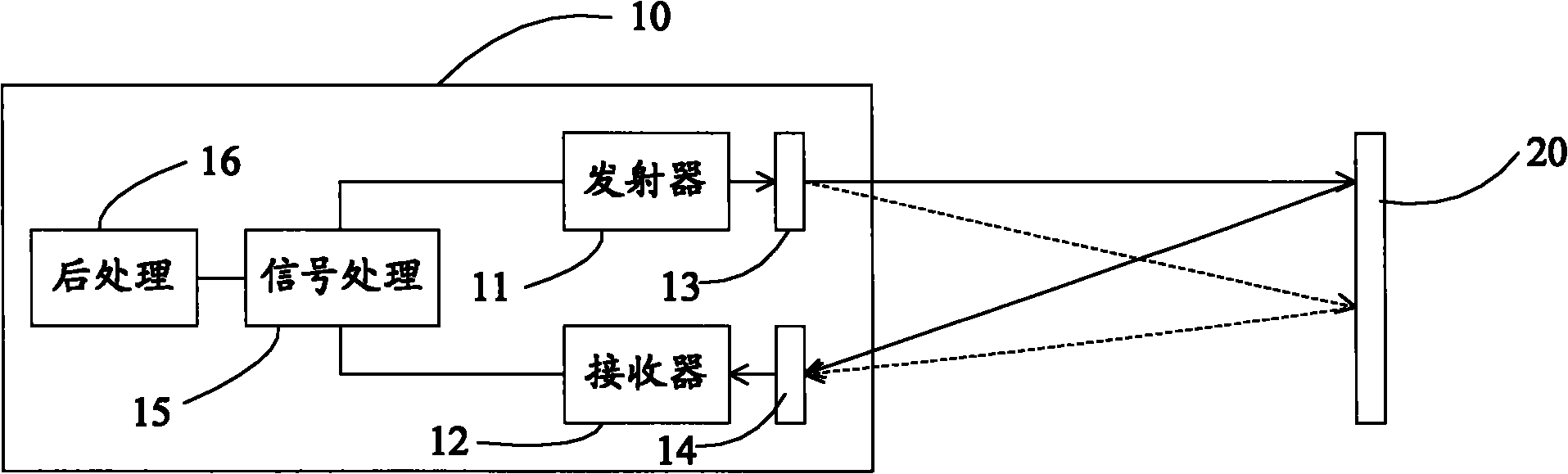

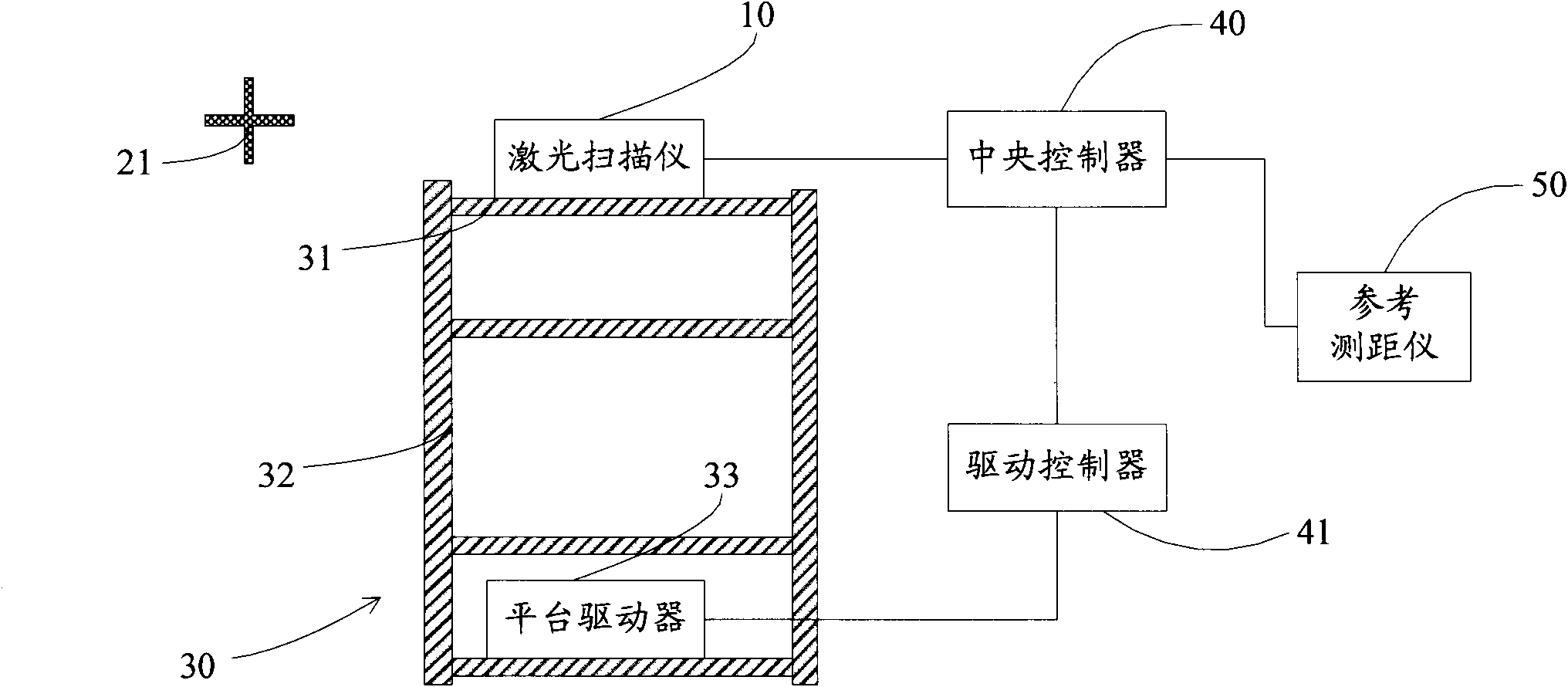

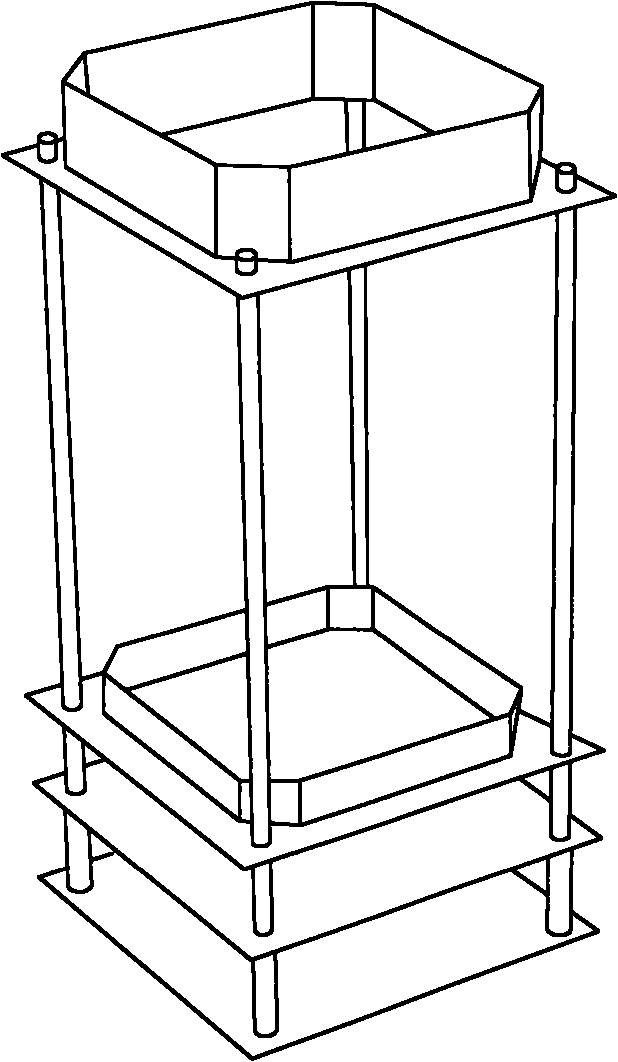

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings. first reference figure 2 , which is a schematic diagram of the composition and structure of an embodiment of the laser scanner calibration system of the present invention. Wherein, the laser scanner 10 is located on the controllable precision lifting platform 30, and can be raised and lowered together with the lifting platform, and the lifting platform is driven by its platform driver to move up and down. A plurality of marker points 21 are arranged around the laser scanner, and the number of marker points should at least meet the requirement of identifying the parameters of the coordinate transformation matrix between the instrument coordinates of the laser scanner and the local coordinates of the reference rangefinder. On this basis, the position and distribution of the marker points can be flexibly designed according to the different emphases of the error categori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com