Positioning method based on infrared light spots

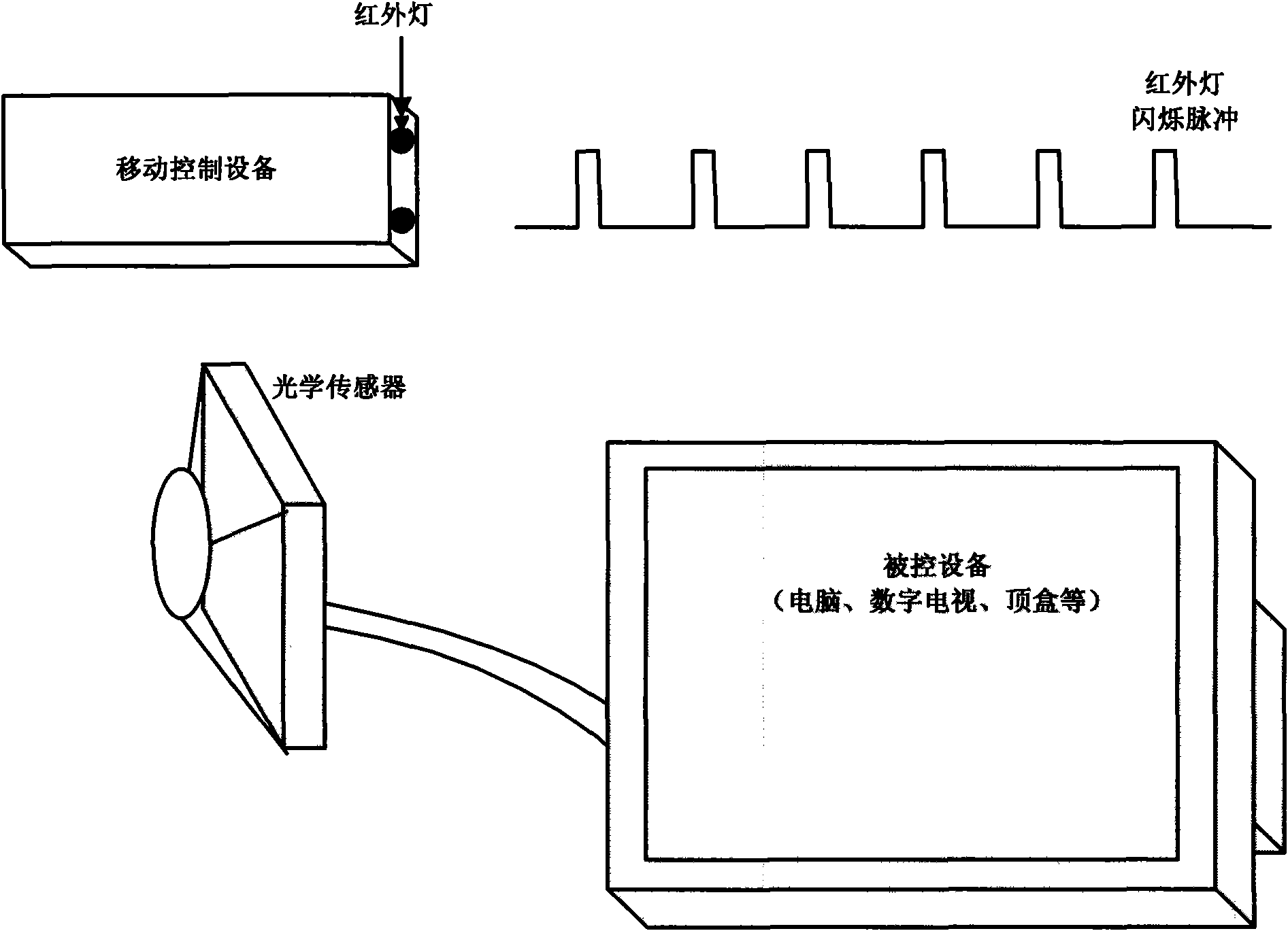

An infrared light and point positioning technology, applied in the field of positioning, can solve the problems of increased power consumption of mobile control equipment, increased product cost, etc., and achieve the effects of benefiting power consumption control and cost control, reducing power consumption, and reducing information processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The specific process of embodiment one is as follows Figure 4 shown.

[0059] Optical sensor controlled device side:

[0060] 1. The optical sensor connected to the controlled device scans the external infrared light spots at a fixed scanning speed (for example, 300 frames per second);

[0061] 2. Determine whether any infrared light spots are scanned, if not, proceed to the next scan, if found infrared light spots, go to step 3;

[0062] 3. Analyze the size and shape of the infrared light spots. The infrared light spots that meet the conditions are retained as effective infrared light spots, and the infrared light spots that do not meet the conditions are filtered out. In order to prevent other external interference light sources from adversely affecting the positioning;

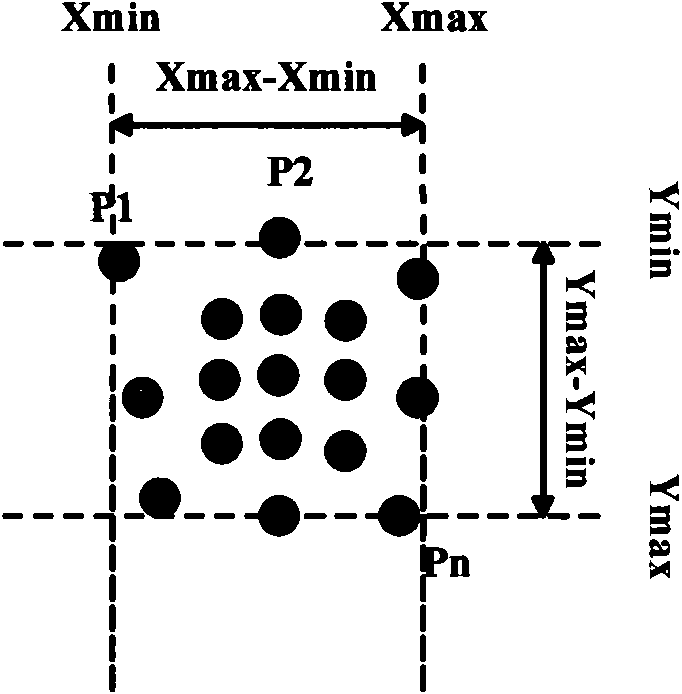

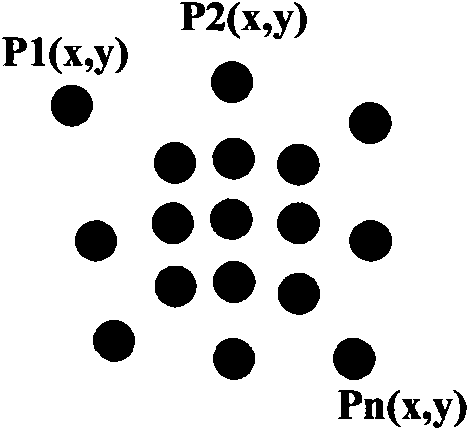

[0063] 4. Calculate the plane positioning position of the infrared light point (for the case of multiple infrared light points, the distance between the infrared light points should also be calcu...

Embodiment 2

[0070] The concrete process of embodiment two is as follows Figure 5 shown.

[0071] Optical sensor controlled object side:

[0072] 1. The optical sensor scans the external infrared light spot at its fastest scanning speed (for example: 500 frames per second), such as Figure 7 shown;

[0073] 2. Calculate the frequency of the infrared light switch, the specific time of turning on and off through the obtained external infrared light flashing information;

[0074] 3. Adjust the scanning frequency of the optical sensor to be the same as the switching frequency of the infrared light, and make sure that the start time of scanning is when the infrared light is turned on and turned on steadily (for example: if the time for the infrared light to be turned on is divided into 3T equal parts, the scanning time is at the infrared about 1 / 3T after the light is on);

[0075] 4. The optical sensor scans according to the adjusted scanning start time and scanning frequency;

[0076] 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com