A control method for wire arrangement of enameled wire take-up machine

A control method and technology of wire take-up machine, applied in digital control, electrical program control, transportation and packaging, etc., can solve the problems of eye safety hazards, high maintenance difficulty, difficult adjustment, etc., to achieve neat and well-proportioned appearance, considerable economic benefits, The effect of less manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

[0035] The invention relates to a control method for wire arrangement of an enameled wire take-up machine. This method is carried out in combination with the obtained independent intellectual property rights-utility model patent: digital control wire arrangement device for enameled wire take-up machine, patent number: CN200420090429.6, the device is a The take-up and discharge device suitable for all I-shaped take-up reels. The present invention specifically includes:

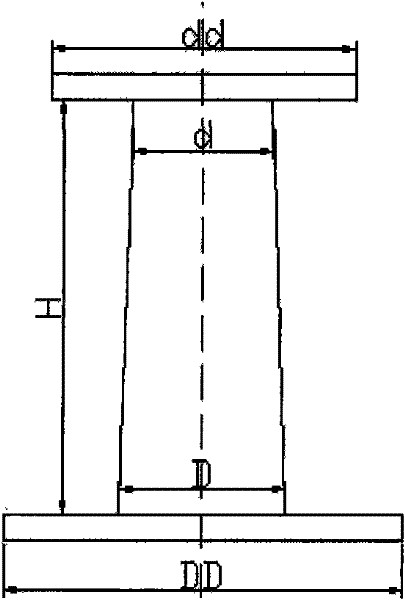

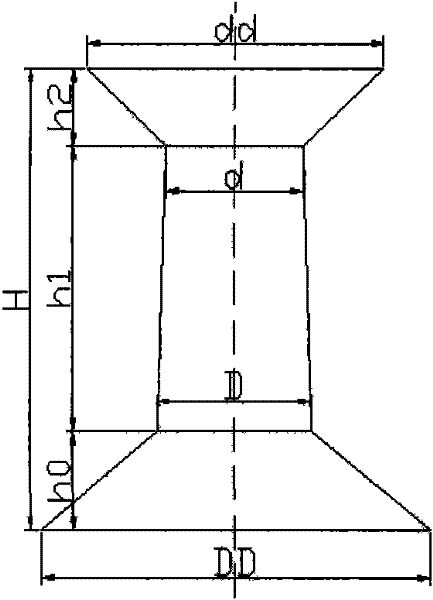

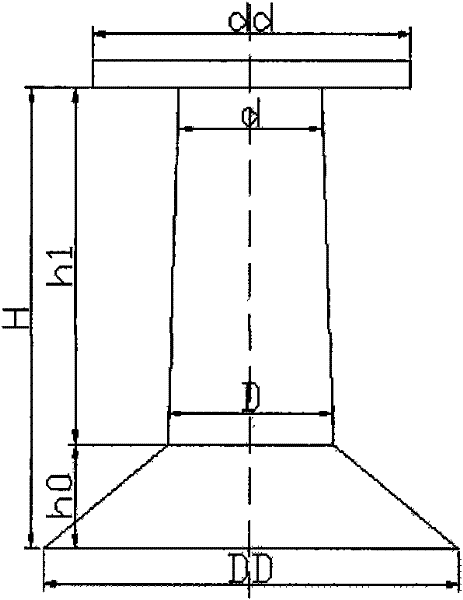

[0036] After analyzing the shape characteristics of all the take-up reels, a parameter model for expressing the shape and size of the take-up reels is established with 8 parameters, so that the I-shaped take-up reel becomes a double-cone take-up reel with special specifications , at this moment height h0=h2=0, the take-up reels of various shapes and sizes are set up different databases according to the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com