Maximum power factor control method of intermediate frequency power supply induction heating apparatus

A technology of induction heating device and intermediate frequency power supply, which is applied in the direction of induction heating control, induction heating, etc., and can solve the problems of increased coil temperature rise, reduced heating efficiency, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

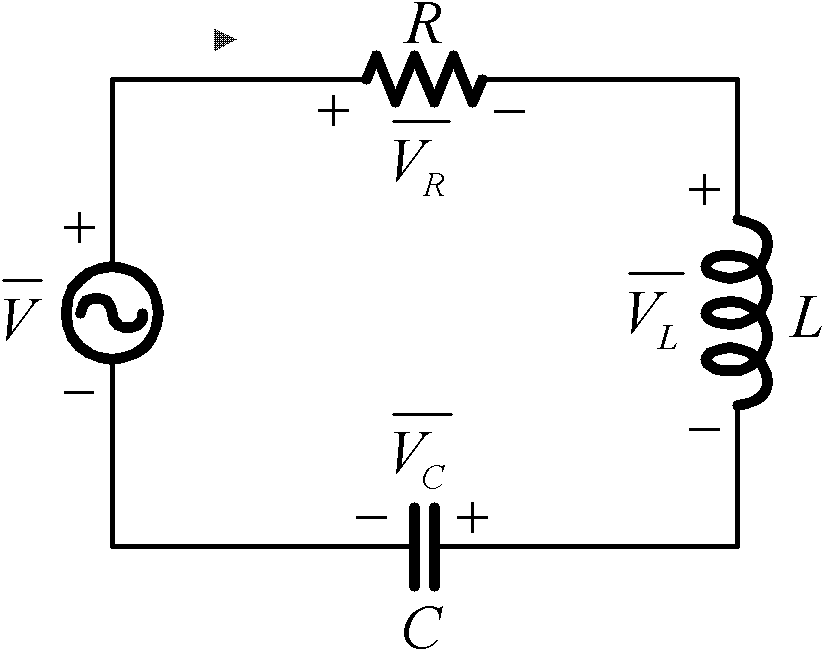

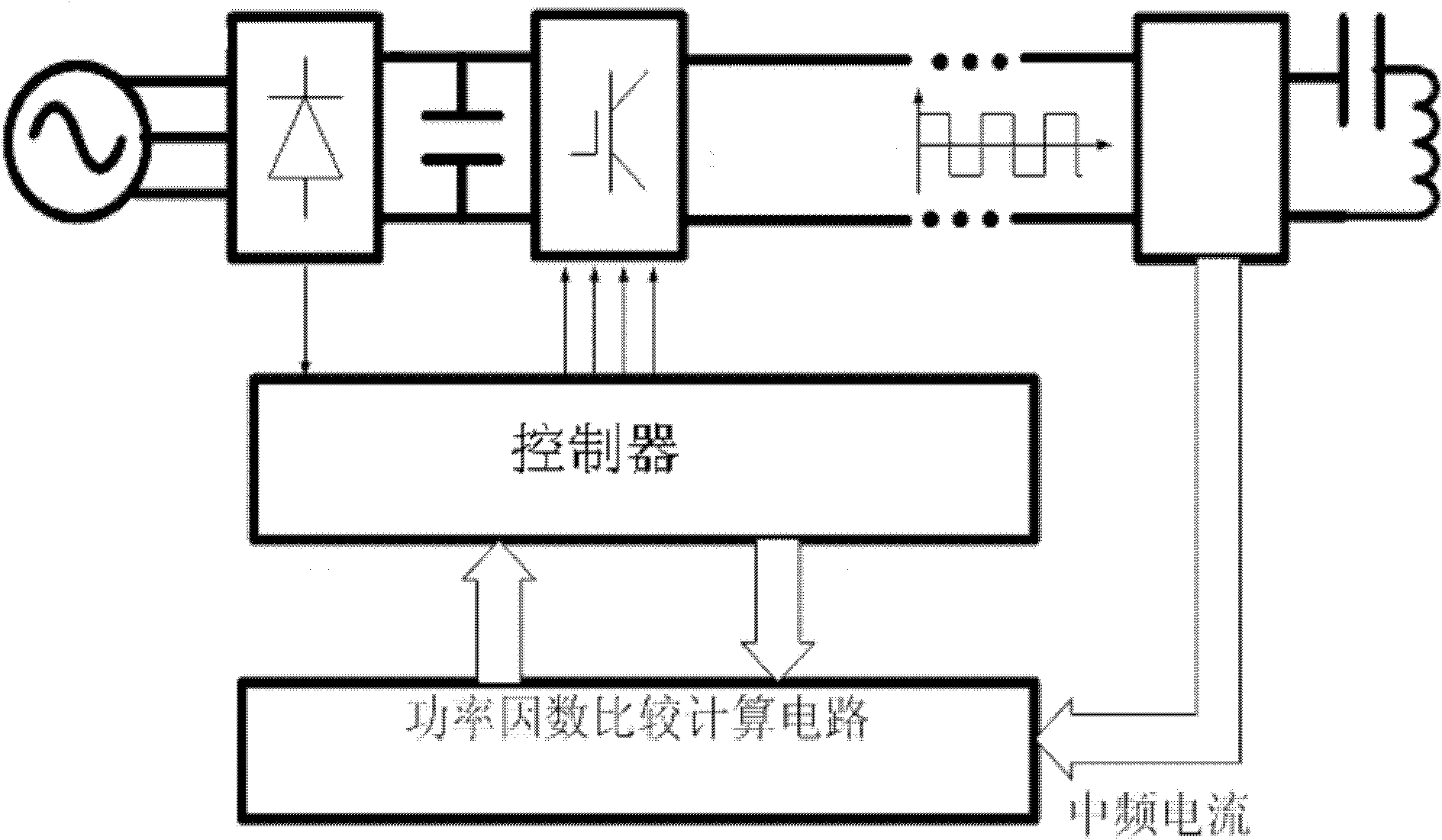

[0014] The following is an R-L-C series resonant circuit to illustrate the principle of the power factor control method. The system principle is as follows: figure 1 As shown in the figure, R, L, and C are the resistance, inductance, and capacitance of the power resonant circuit respectively. The system resonant frequency is determined by the inductance and capacitance of the resonant circuit, as shown in the following formula:

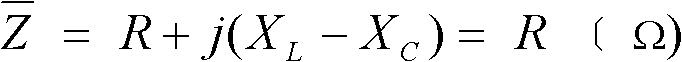

[0015] When the circuit resonates (X L =X C ):

[0016]

[0017] When f<f0, reactance XL<XC, the circuit is capacitive.

[0018] When f = f0, reactance XL = XC, the circuit is resistive. At the time of resonance, the circuit impedance Z0=R is the minimum and produces the maximum current.

[0019] When f>f0, reactance XL>XC, the circuit is capacitive

[0020] Where f is the output frequency of the intermediate frequency power supply, XL is the system inductive reactance, and XC is the system capacitive reactance.

[0021] It can be seen that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com