Speaker diaphragm, speaker using said diaphragm, and speaker diaphragm manufacturing method

A manufacturing method and speaker technology, applied in the sensor, diaphragm structure, fiber diaphragm and other directions, can solve the problem that the inorganic fiber woven cloth 201 and the natural fiber non-woven fabric 202 cannot be integrated, internal loss is difficult, and the sound quality of the speaker cannot be fully realized. Improve and other problems to achieve the effect of increasing Young's modulus, increasing internal loss, and improving sound quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Next, the configuration of an embodiment of the present invention will be described with reference to the drawings.

[0058] (Embodiment 1)

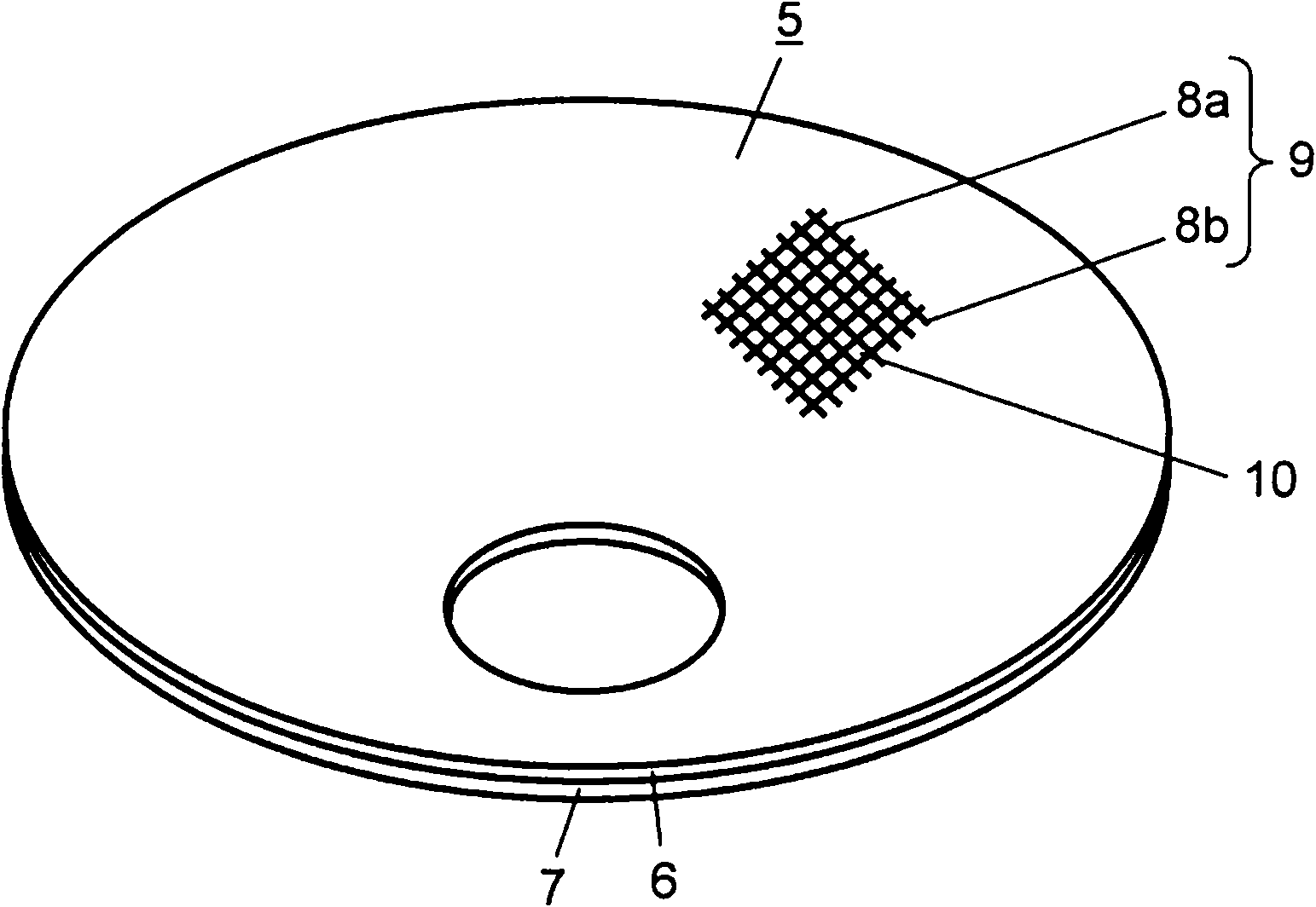

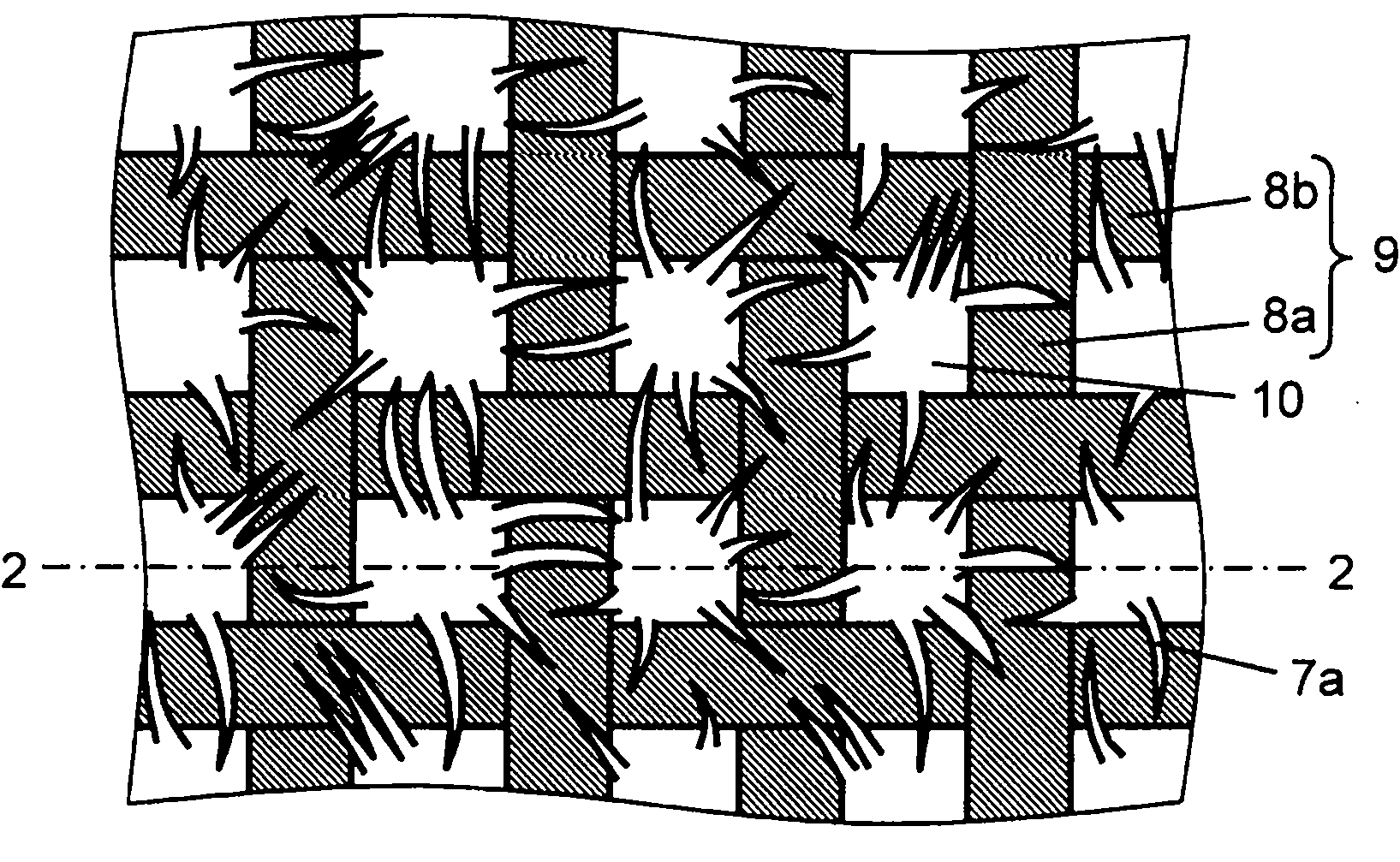

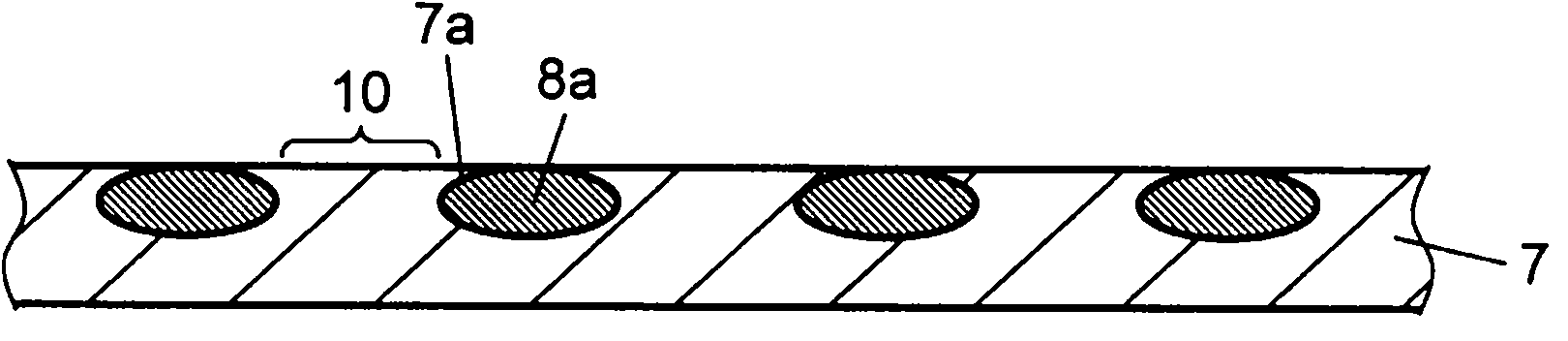

[0059] Fig. 1 is a perspective view of a speaker diaphragm according to Embodiment 1 of the present invention. In FIG. 1(A) , speaker diaphragm 5 has a two-layer structure of a fabric layer 6 and a paper layer 7 . The woven fabric layer 6 is formed by weaving two kinds of weaving yarns 9 , the warp yarns 8 a and the weft yarns 8 b , in a grid pattern, and the grid stripes are exposed on the surface of the speaker diaphragm 5 . A thermosetting resin (not shown) exists inside and outside these longitudinal yarns 8a and weft yarns 8b, and by thermal curing of the thermosetting resin, the longitudinal yarns 8a and weft yarns 8b themselves and are formed by weaving them together. The fabric layer 6 is in a cured state. In addition, the fabric layer 6 has a structure containing at least one of high-strength fibers such as aramid fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com