Intravenous infusion set capable of exhausting air automatically

An intravenous infusion and automatic exhaust technology, applied in the field of medical devices, can solve the problems of easy inclination, high cost, and low production efficiency, and achieve the effects of guaranteed sealing performance, low production cost, and long radial distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

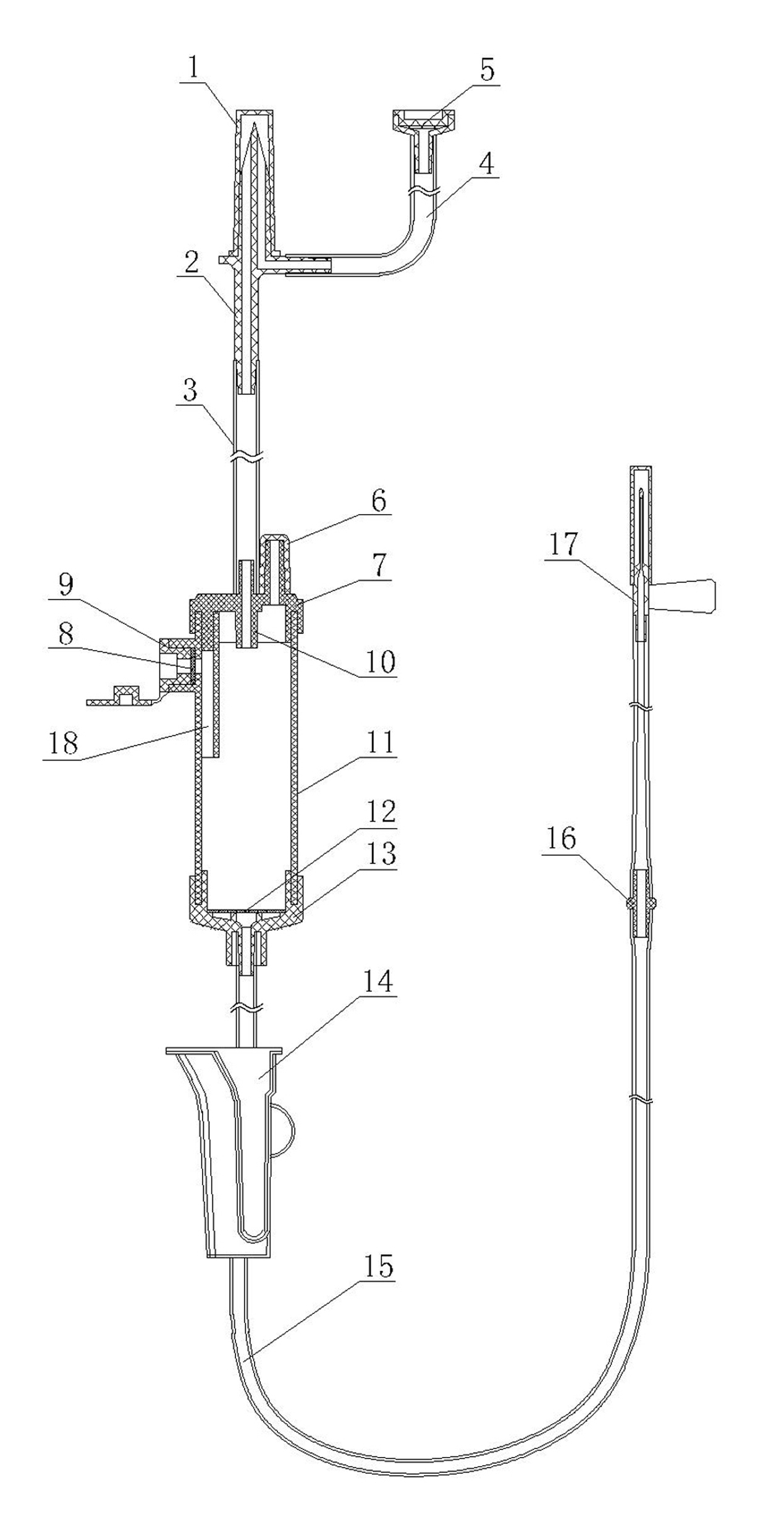

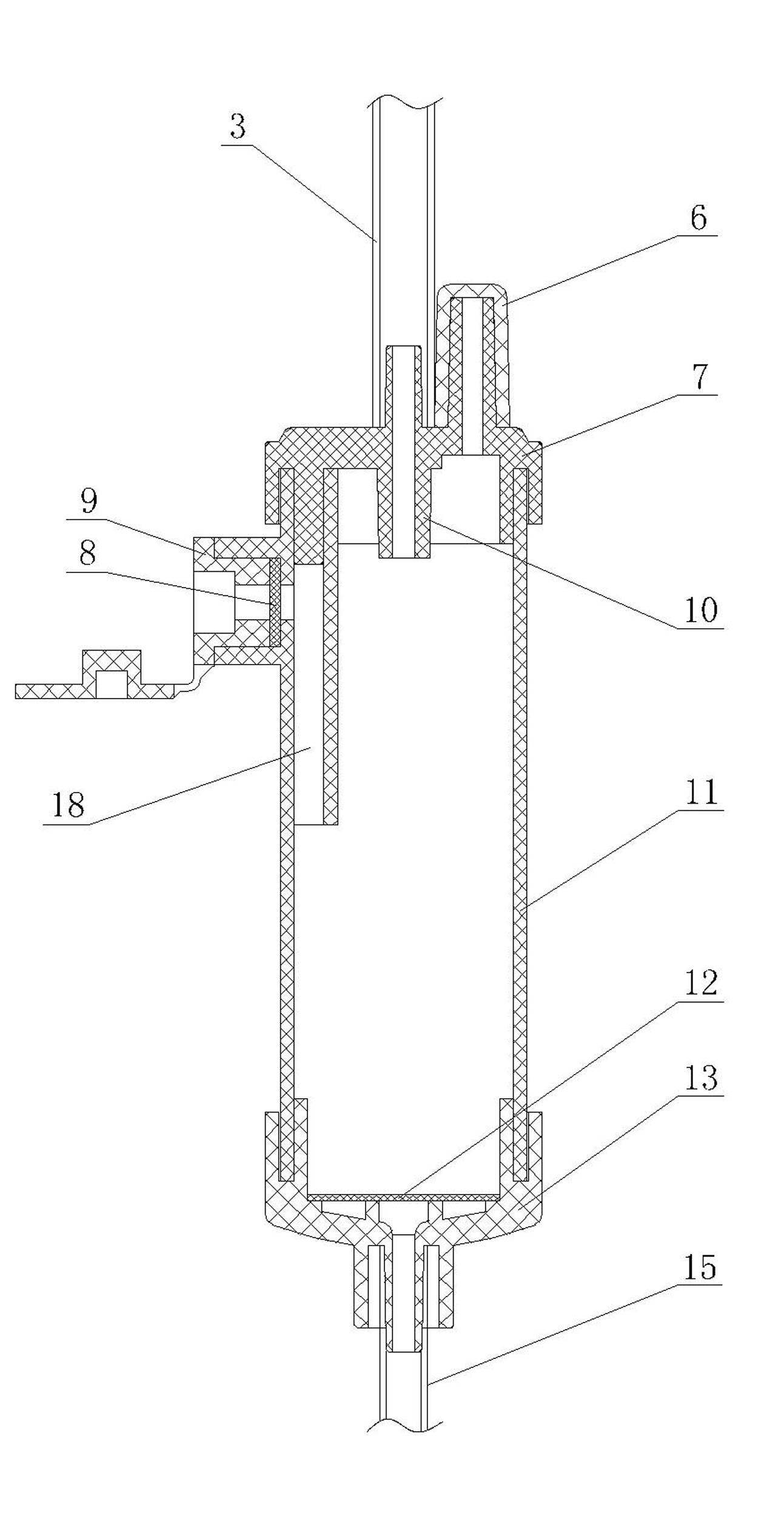

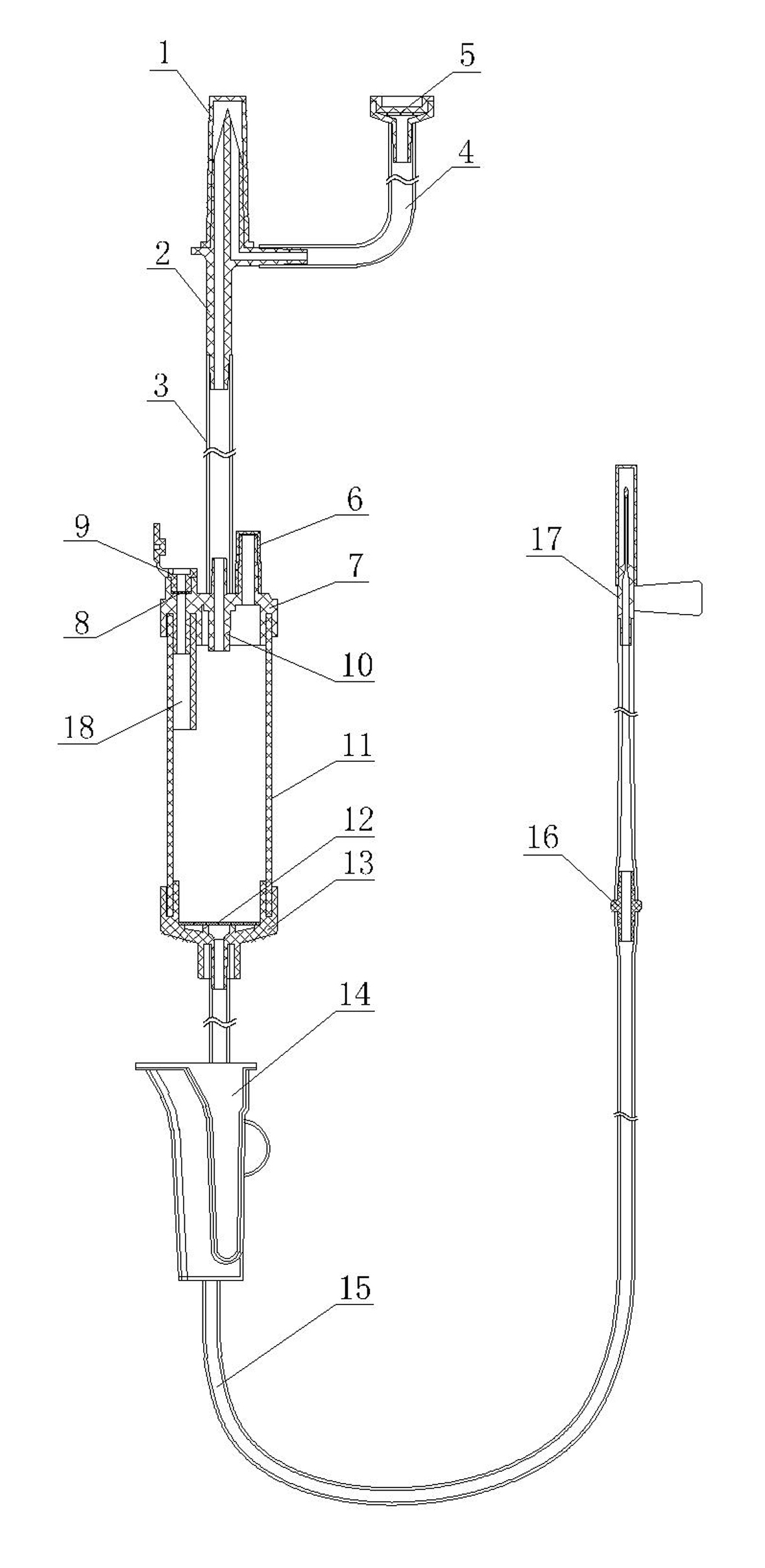

[0025] Such as Figure 1-Figure 15 As shown, the automatic venting venous infusion set of the present invention includes a liquid inlet assembly, a dripping funnel 11, a liquid outlet assembly and a disposable intravenous injection needle 17 connected in sequence, wherein the upper opening of the dripping funnel 11 is sealed The cover is provided with a dripping funnel cover 7, and the dripping funnel cover 7 is provided with a dropper 10 extending into the dropping funnel 11 and a medicinal liquid injection piece 6 for adding medicinal liquid. It is connected to the upper part of the dropper 10, the liquid outlet assembly is connected to the liquid outlet below the dripping funnel 11, and the disposable intravenous injection needle 17 is connected to the outlet of the liquid outlet assembly. The upper part of the side wall of the dropping funnel 11 is integrally formed with at least one Air-guiding cavity 18, and each air-guiding cavity 18 bottoms are connected with dropping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com