Extrusion coating machine and coating system thereof

A technology of extrusion coating and coating machine, which is applied to the surface coating liquid device, coating, electrical components, etc., which can solve the problems of complex structure, waste of raw materials, and manpower consumption of high-sensitivity control valves, and achieve improved Gap coating quality, easy cleaning, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

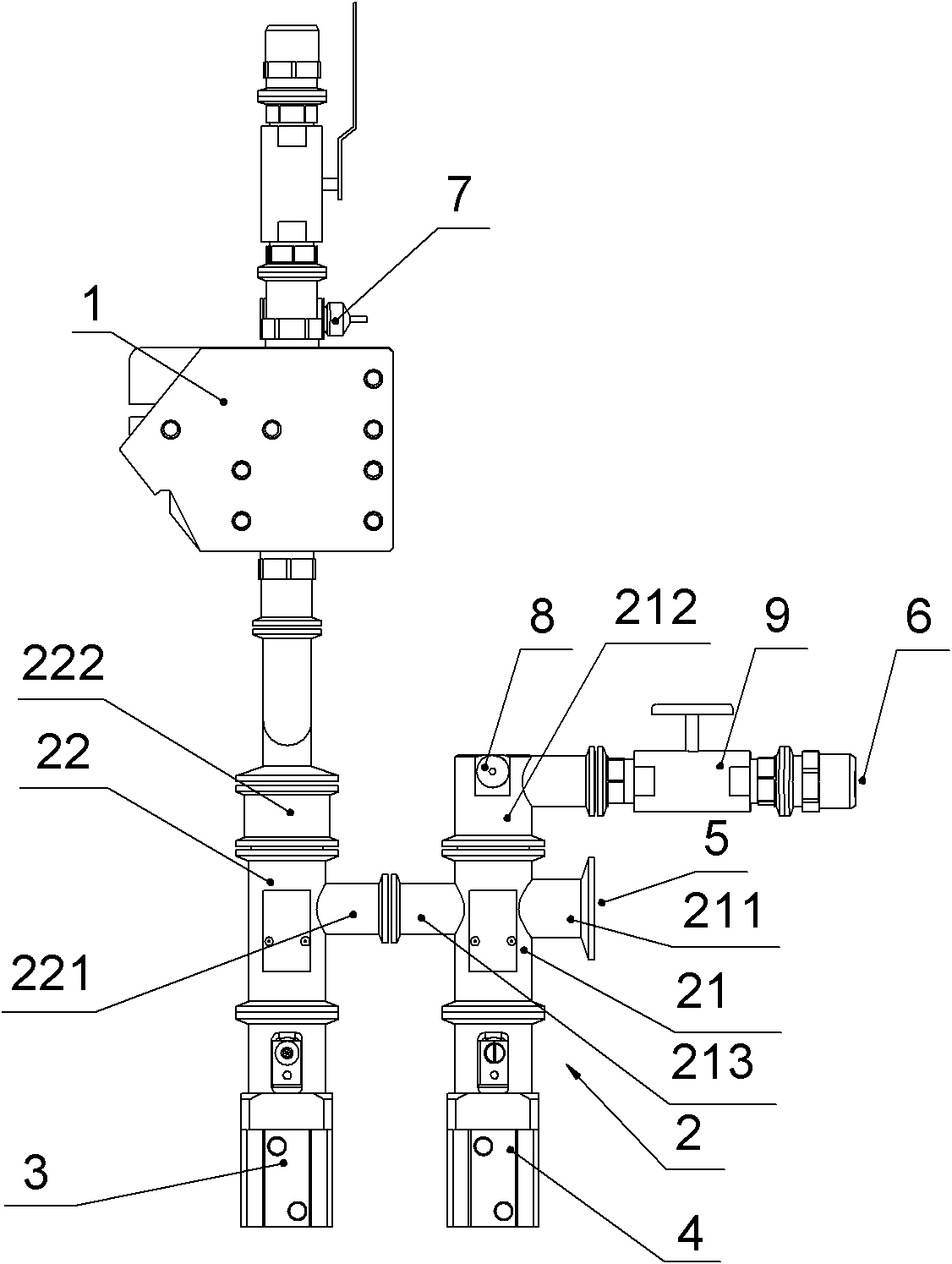

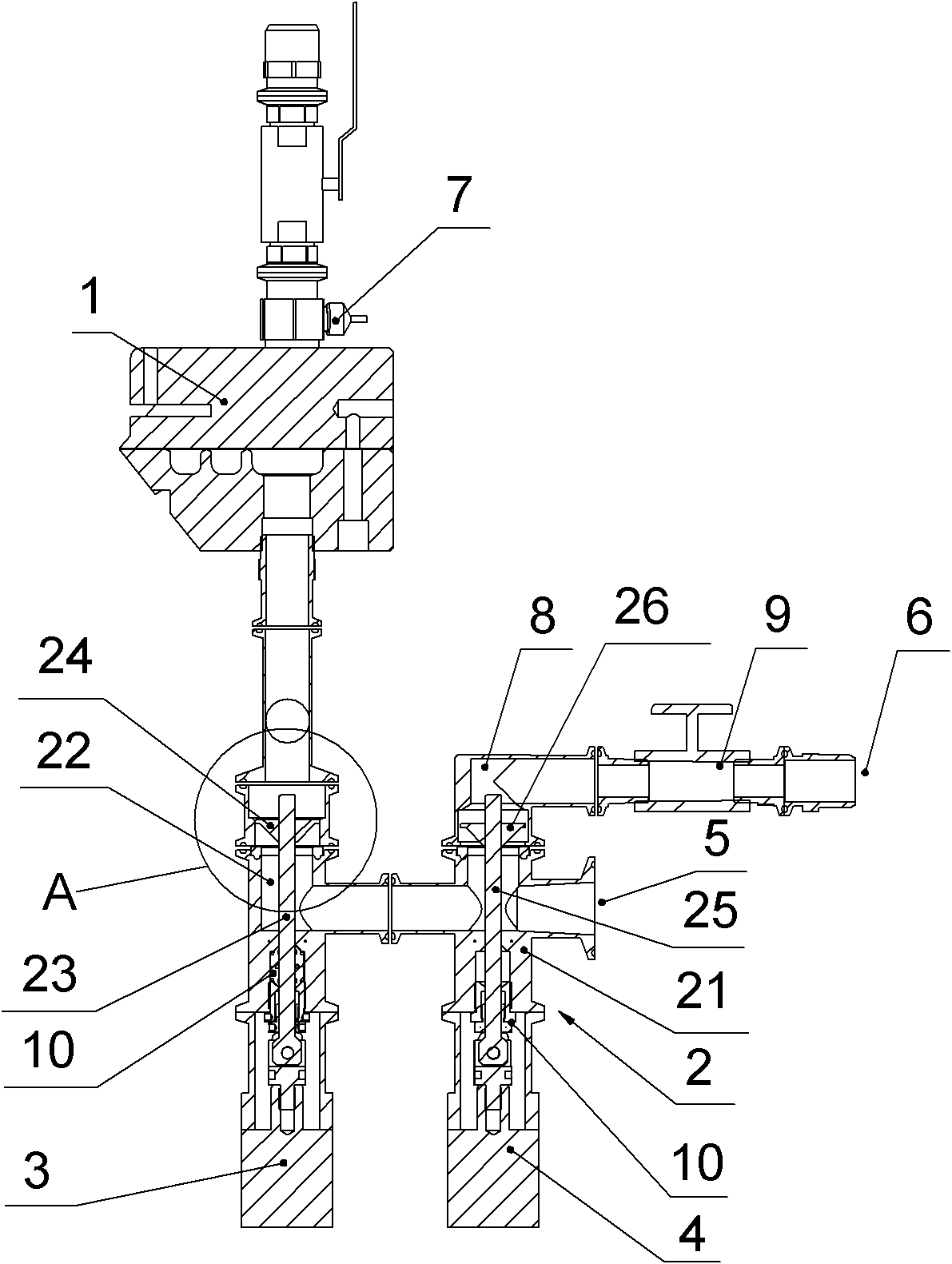

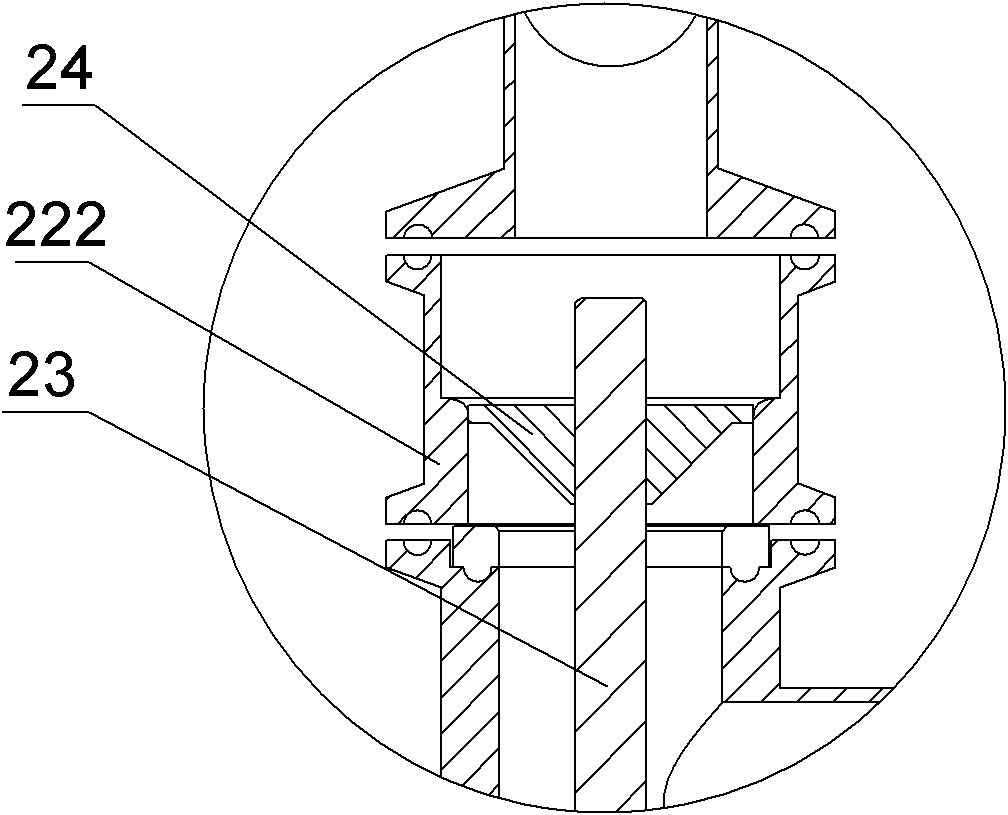

[0024] As an embodiment of the coating system of the extrusion coater of the present invention, please refer to figure 1 with figure 2 , including an extrusion head 1, a control valve 2 and a control system, the valve body of the control valve 2 includes a three-way valve 21 and a two-way valve 22, the first end 211 of the three-way valve is the feed end, and The feed port 5 is connected, the second end 212 of the three-way valve is connected with the return port 6, the third end 213 of the three-way valve is connected with the first end 221 of the two-way valve, and the second end 222 of the two-way valve is connected with the extrusion The head 1 is connected, the second end 212 of the three-way valve is provided with a return valve co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com