Cleaning device of plug-in smoke gas on-line monitor probe

A technology of cleaning device and monitoring instrument, which is applied in the directions of cleaning methods, cleaning methods and utensils using gas flow, and cleaning methods using tools, etc. Easy recovery, short time consuming, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

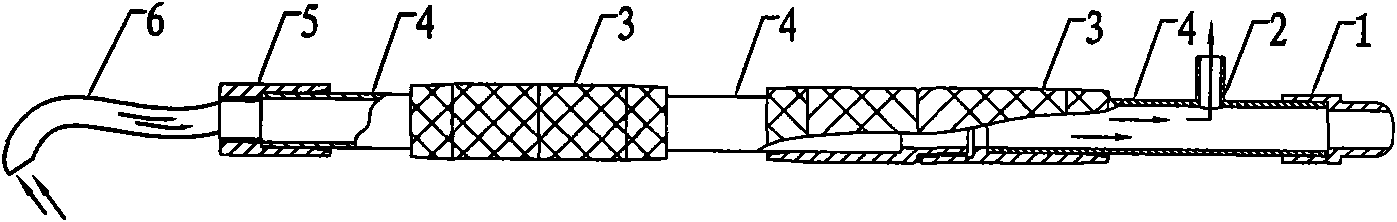

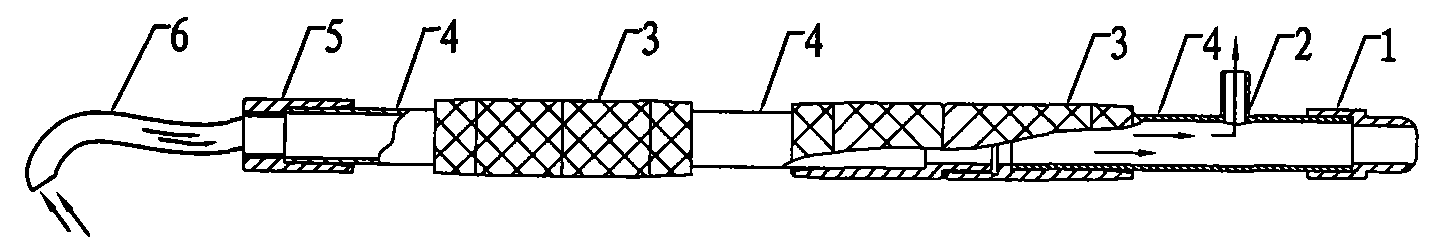

[0010] Such as figure 1 As shown, the hollow pipe body 4 is made up of several sections, and the sections are connected by pipe joints 3; The front end of the pipe body 4 has a horizontal air nozzle 1 opening in the axial direction of the pipe body 4 and a side air nozzle 2 opening in the radial direction of the pipe body. The tail end of the pipe body 4 is provided with a joint 5 connected to the compressed air pipe 6. The joint 5 one end has the interface that pipe body 4 inserts.

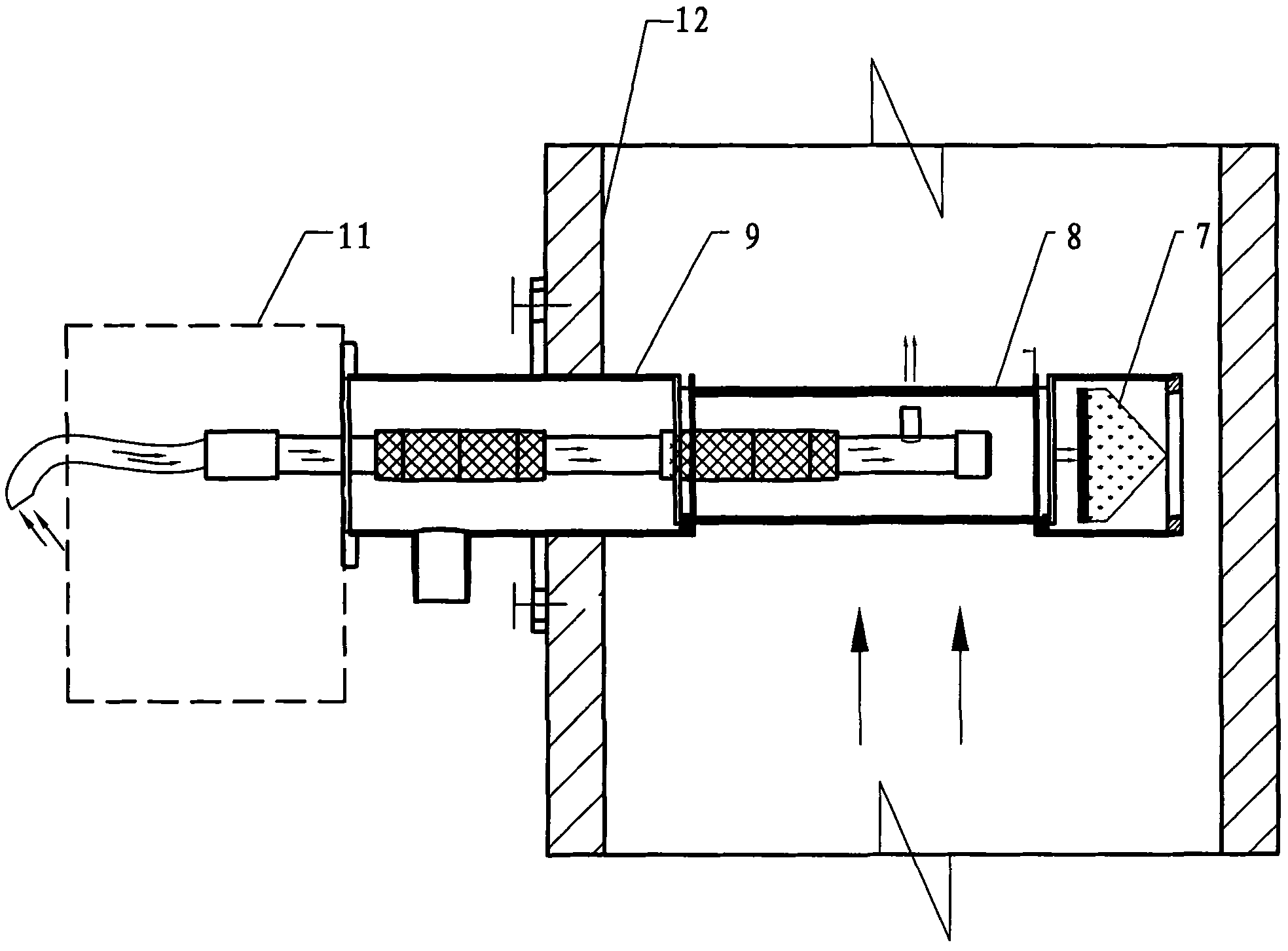

[0011] Specific operations such as figure 2 As shown: a, open the spectrometer 11 to expose the inner cavity of the probe 9; b, extend the device into the inner cavity of the probe 9, and use the two gas nozzles 1 and 2 at the front end and the auxiliary tools installed to scrape and wipe the measuring groove Dust accumulation in section 8; c, take out the device and install soft objects such as cotton yarn for cleaning on the first gas nozzle 1, then re-enter the probe cavity, and use the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com