Ceramic tile cutting machine

A cutting machine and tile technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of no safety device and poor processing quality, and achieve the effect of simple structure, improved cutting quality and efficiency, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

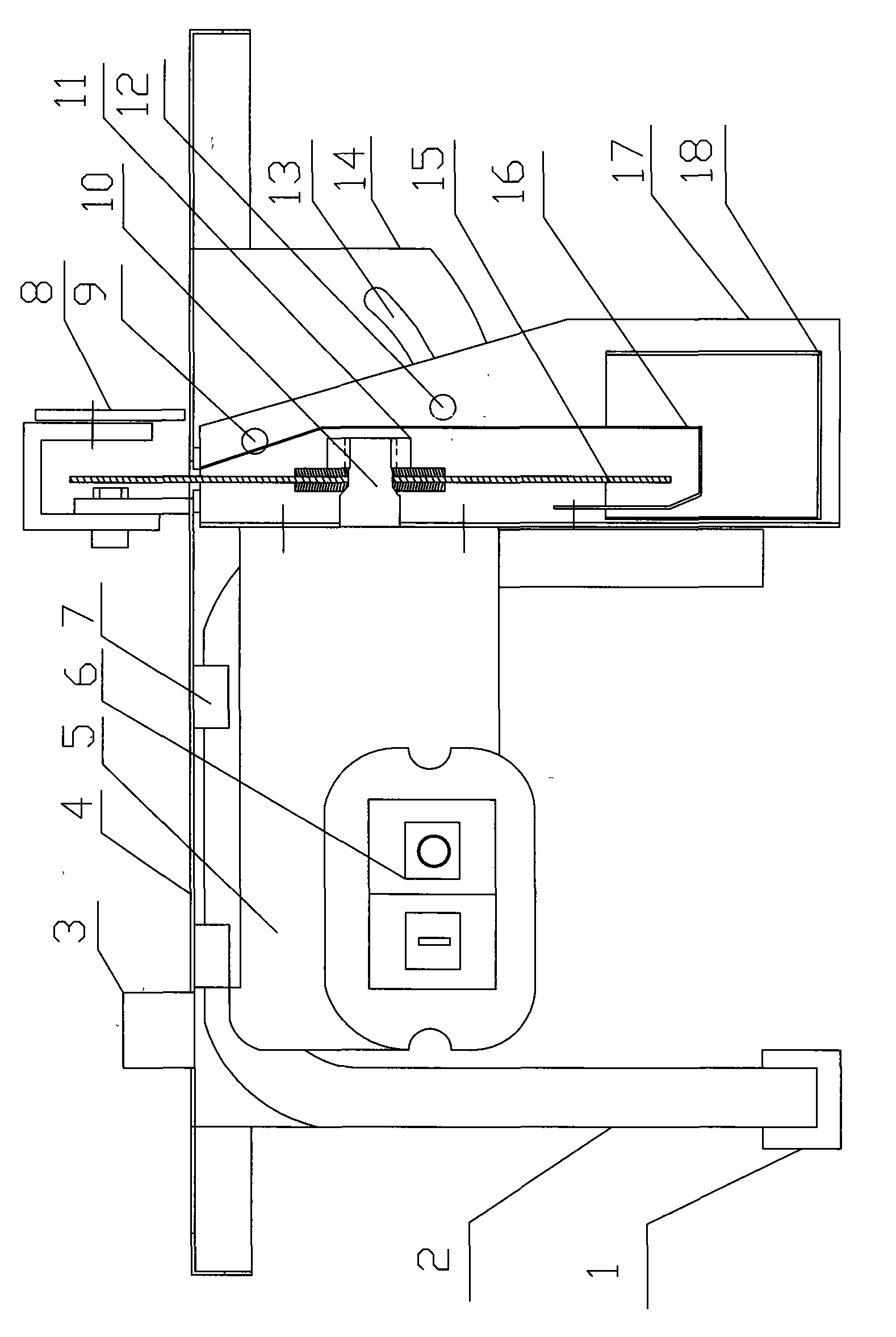

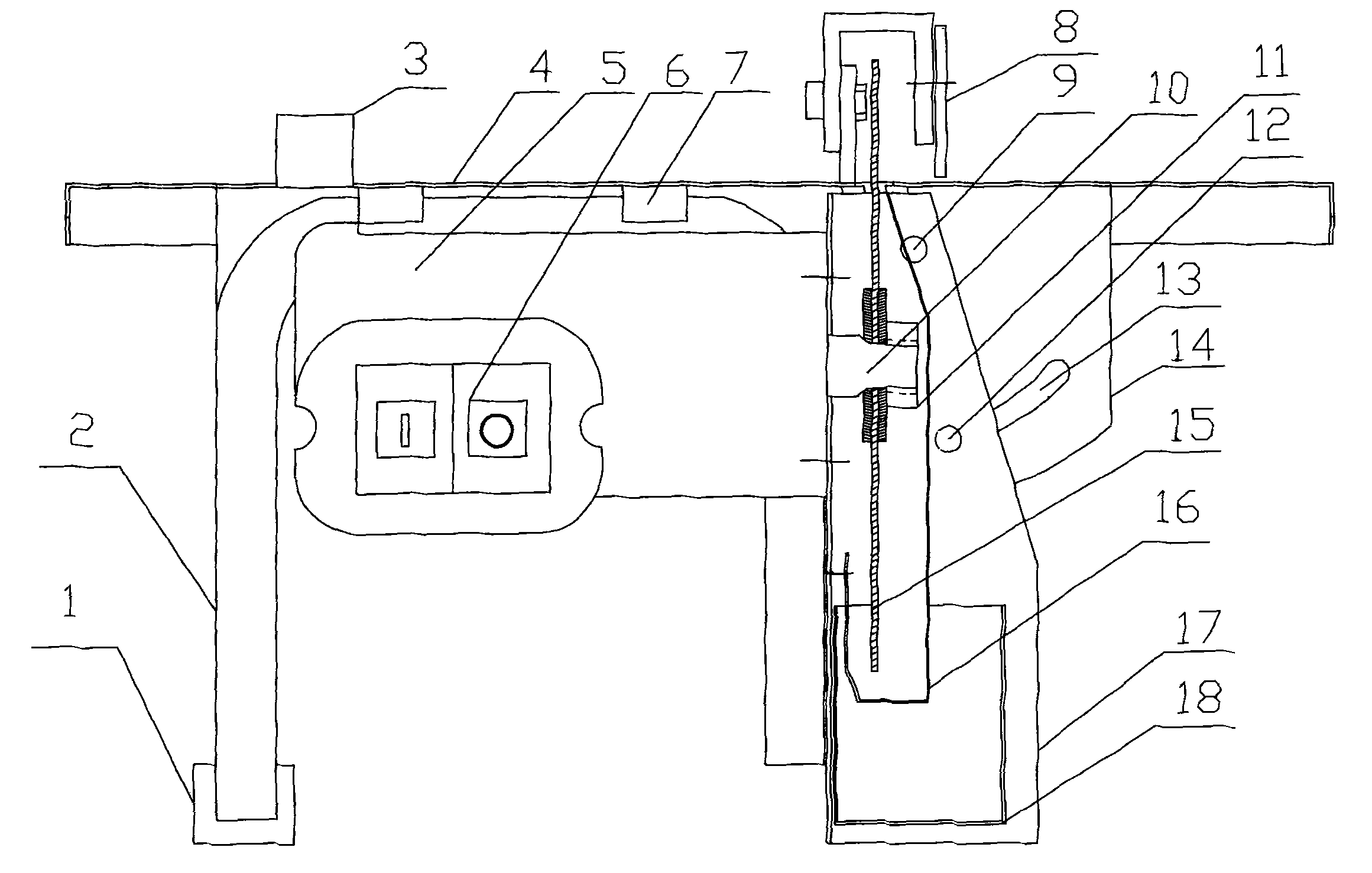

[0015] A kind of tile cutting machine, comprises motor 5, cutting piece 15, and motor 5 is provided with support 17, and the motor shaft 10 outside support 16 is provided with cutting piece 15, is positioned with spacer and nut 11; Be provided with workbench 4, The workbench 4 can rotate, and the workbench 4 is provided with a cutting piece 15 mounting opening, a cutting piece 15 upper shield 8, a workpiece backrest 3 and a scale.

[0016] The cutting piece 15 is provided with an upper shield 8 above the workbench 4, and a lower shield 16 is provided below the workbench 4.

[0017] A water tank 18 is arranged outside the guard 16 under the cutting piece 15, and its water level contacts with the cutting piece 15 limits.

[0018] The workbench 4 can be rotated by the rotation axis 9, and the rotation angle is 0-45°.

[0019] The workbench bracket 14 is movably engaged with the motor bracket 17, the rotation angle is determined through the guide groove 13, and the bolt 12 is pos...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap