Hydraulic control system with multisegment grab

A hydraulic control system and grab technology, applied in the direction of fluid pressure actuators, load suspension components, servo motors, etc., can solve the problems of less grasping and loose objects to be grasped, so as to reduce operation errors and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with specific embodiment:

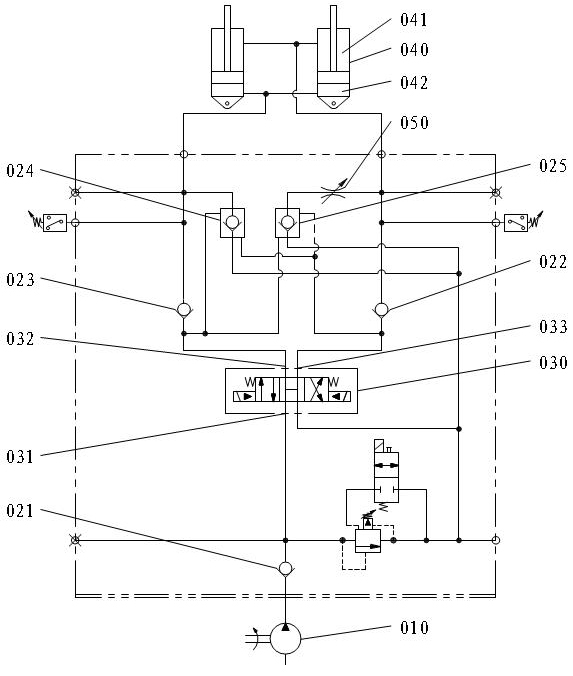

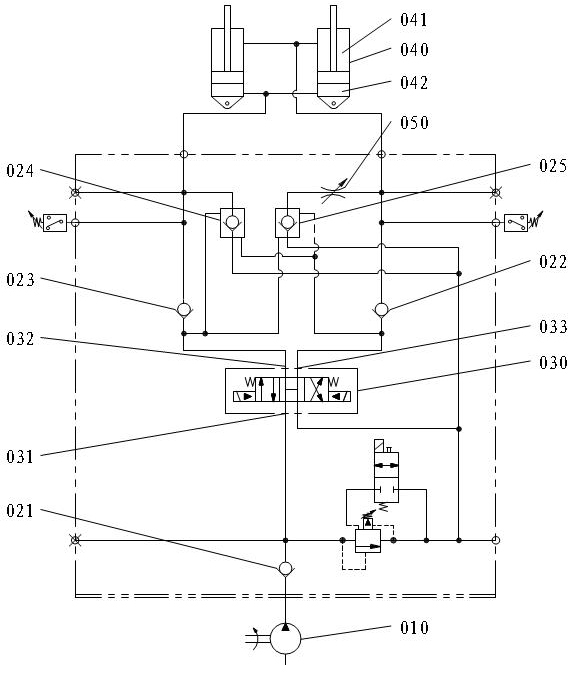

[0025] See figure 1 , which is a schematic diagram of the system of the present invention, including an oil pump 010, a reversing valve 030, an oil cylinder 040 and an external oil tank.

[0026] The reversing valve 030 is a three-position four-way electro-hydraulic valve. The reversing valve 030 has an oil inlet 031 , a first oil outlet 032 and a second oil outlet 033 . The reversing valve 030 can adjust the oil outlet through the valve, so that the first oil outlet 032 outputs oil or the second oil outlet 033 outputs oil.

[0027] There are six oil cylinders 040, and each oil cylinder 040 controls one lobe of the multi-lobe grab bucket respectively. The oil cylinder 040 has an oil cylinder upper chamber 041 and an oil cylinder lower chamber 042, and a piston is arranged between the oil cylinder upper chamber 041 and the oil cylinder lower chamber 042.

[0028] The oil pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com