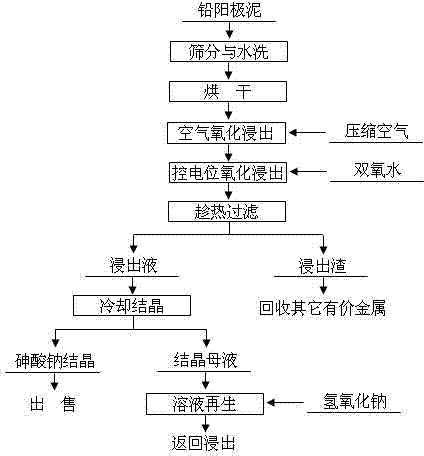

Method for removing and recovering arsenic from lead anode slime

A lead anode slime and arsenic recovery technology, applied in the direction of improving process efficiency, etc., can solve the problems of poor metal separation effect, difficult stable operation of the production process, low arsenic precipitation rate, etc., achieve low equipment material requirements, and prevent secondary pollution , The effect of stable process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 500g of lead anode slime and wash it with hot water at 80°C for 1~2h under the condition that the liquid-solid ratio L / kg is 4:1, use a sieve with a pore size of 500um to screen out large particle inclusions, and then filter. After washing, the lead anode The slime was baked at 180°C for 36 hours, and the weight of the anode slime was 385g. Its main components were (%) by weight percentage: Pb 11.80, Bi 36.03, Cu 0.66, As 6.25, Sb 13.74 and Ag 4.11; industrial grade hydroxide Sodium, in which the content of NaOH is ≥96%; industrial grade hydrogen peroxide, in which H 2 o 2 content ≥ 30%.

[0032]Add 750ml of water into a 1500ml reactor, then add 65.0g of industrial sodium hydroxide of the above-mentioned ingredients, install the potential measuring device, adjust the stirring speed to 400r / min, heat the solution until the reaction temperature is 80°C, add the lead of the above-mentioned ingredients The anode slime powder is 150g, and the potential displayed by th...

Embodiment 2

[0035] Take 600g of lead anode slime and wash it with hot water at 80°C for 1~2h under the condition that the liquid-solid ratio L / kg is 4:1, use a sieve with a pore size of 500um to screen out large particle inclusions, and then filter. After washing, the lead anode The slime was baked at 180°C for 36 hours, the weight of the anode slime was 490g, and its main components were (%) by weight percentage: Pb 11.15, Bi 32.17, Cu 1.59, As 7.52, Sb 25.73 and Ag 7.42; industrial grade hydrogen oxide Sodium, in which the content of NaOH is ≥96%; industrial grade hydrogen peroxide, in which H 2 o 2 content ≥ 30%.

[0036] Add 750ml of water into a 1500ml reactor, then add 70.0g of industrial sodium hydroxide of the above ingredients, install the potential measuring device, adjust the stirring speed to 450r / min, heat the solution until the reaction temperature is 80°C, add the lead of the above ingredients The anode slime powder is 150g, and the potential displayed by the potentiomete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com