An electric heating roasting device and roasting method before starting an aluminum electrolytic cell

An electric heating device and an aluminum electrolytic cell technology, applied in the field of aluminum electrolytic cells, can solve the problems of less contact surface between the special-shaped cathode carbon block and the anode carbon block, long roasting time, uneven heating, etc. Improve roasting effect and reduce heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

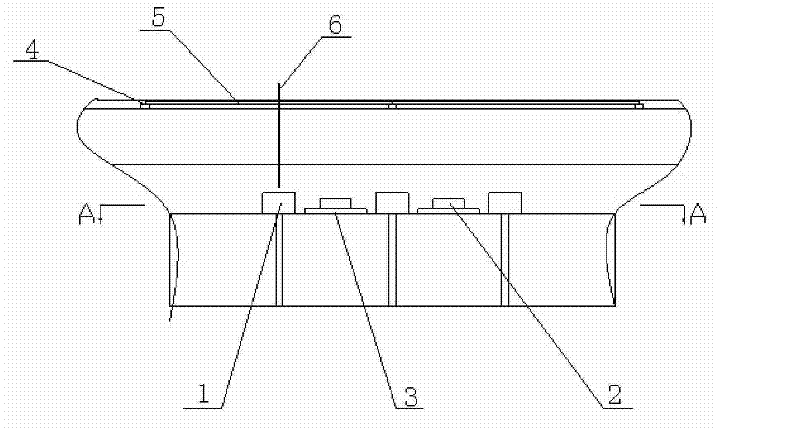

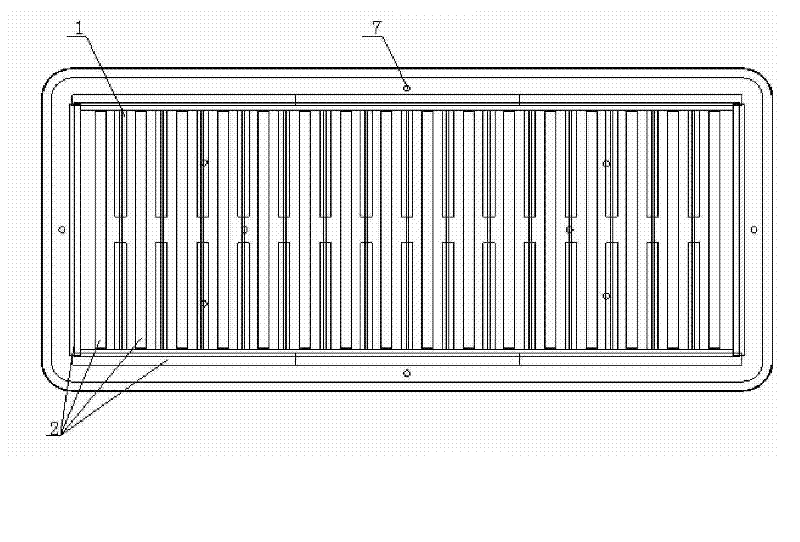

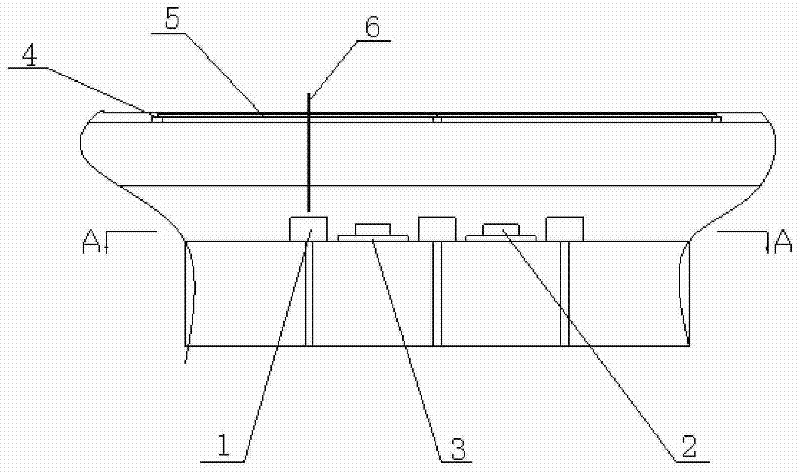

[0017] Example: as figure 1 and figure 2 As shown in the figure, after the fixing of the aluminum electrolytic cell is completed, the upper mechanism of the aluminum electrolytic cell is installed, and the upper mechanism is tested and accepted. Lay and install an electric heating device 2 on the cathode carbon block 1 of the electrolysis cell. The electric heating device 2 is preferably a resistance electrolytic heating device, such as a crawler electric heating device. In this example, a crawler electric heating device 24 is installed on the cathode carbon block 1 of the electrolysis cell. The power of each strip is 15kW. Before laying, 8 temperature monitoring devices 7 are installed on the cathode carbon block 1 of the electrolytic cell to measure and control the temperature. Before laying the crawler-type electric heating device, a 3200×300×25mm aluminum silicate fiberboard 3 is laid flat under each crawler-type electric heating device. After placing the electric heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com