Geothermal well layer-by-layer filter material feeding process

A process method and technology for geothermal wells, applied in the field of drilling, can solve problems such as reducing quality, and achieve the effects of reducing wear, prolonging life, and reducing repeated investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

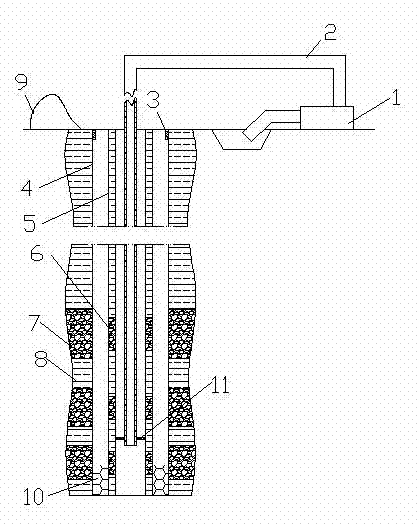

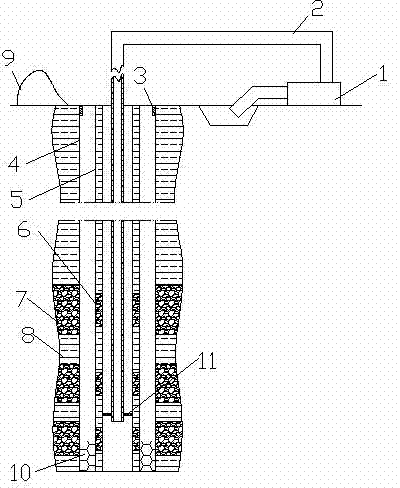

Image

Examples

Embodiment Construction

[0020] The process method of layered filter material in geothermal wells, the process steps are: ①well diameter measurement, ②determine the height of each aquifer and non-aquifer height, ③determine the specific water extraction target layer in the aquifer, ④calculate each specific water extraction target layer The amount of filter material: ⑤Calculate the amount of clay in the non-intake layer and non-aquifer layer in the aquifer, ⑥clear the holes, ⑦change the slurry, ⑧down pipe, ⑨filter pipe flushing, ⑩filter material and clay injection.

[0021] The measurement of the well diameter is to determine the size of the well diameter by a physical measurement method, and to provide data for the next step of calculating the amount of filter material in the water aquifer. The determination of the height of each aquifer and the height of the non-aquifer is the method of geophysical logging. Methods include measuring spontaneous potential, resistivity, natural gamma, acoustic wave, well te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com