Hydraulic self-adaption air valve correct-timing variable system of diesel engine and control method thereof

一种气门正时、自适应的技术,应用在发动机控制、控制润滑剂的压力、机械设备等方向,能够解决很难进排气门调整、制造成本低等问题,达到成本低、结构简单、零部件少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

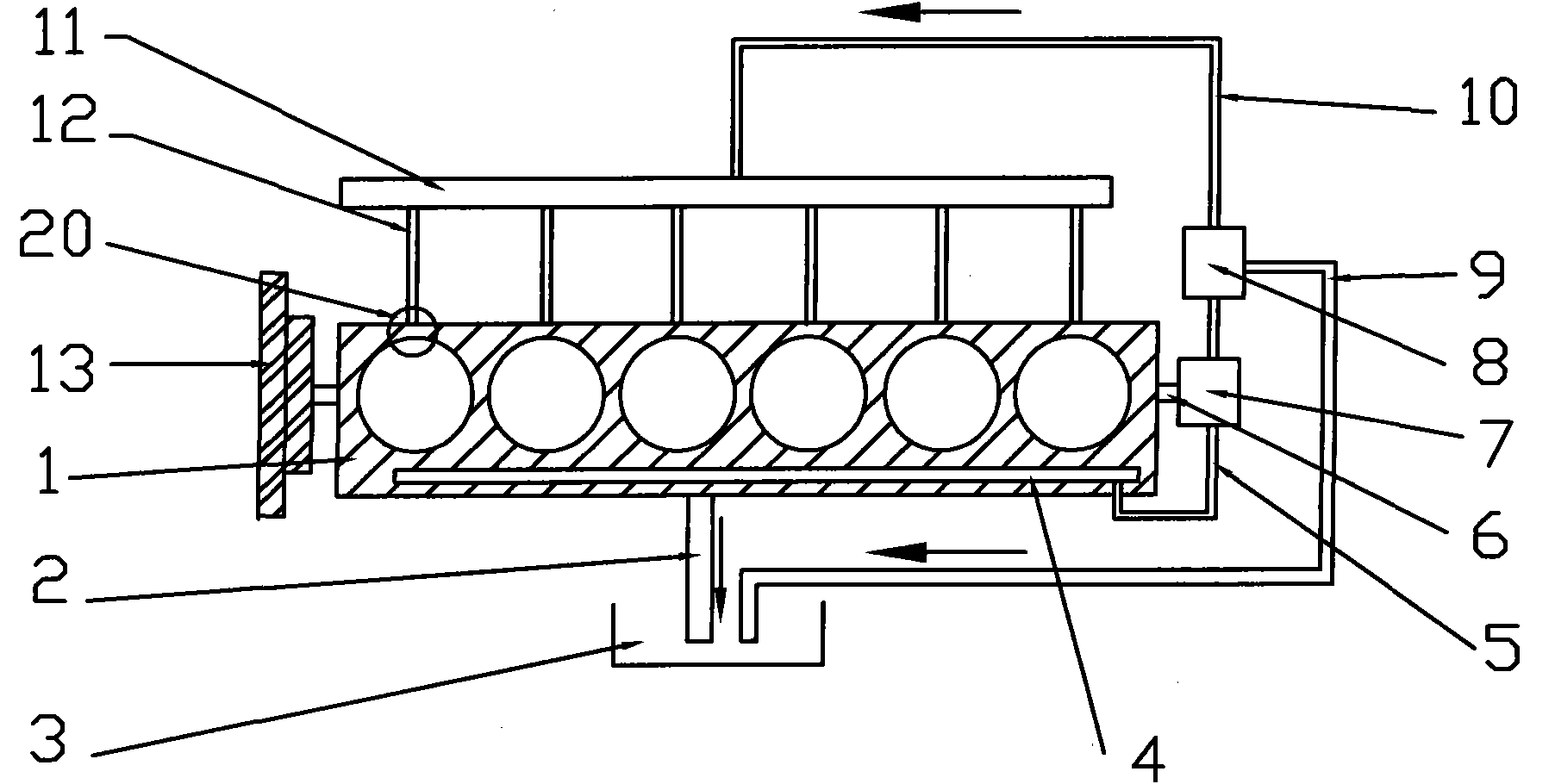

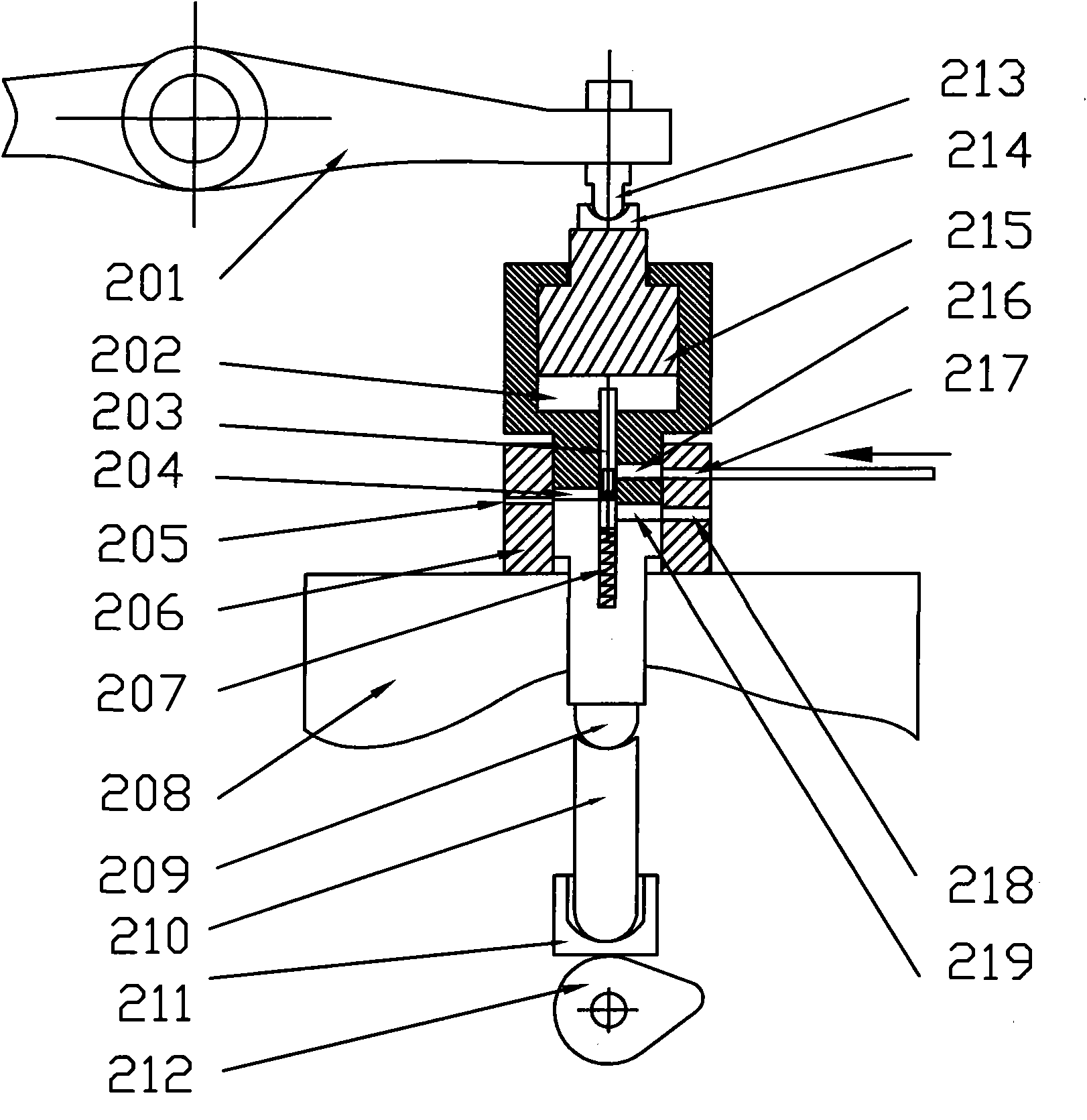

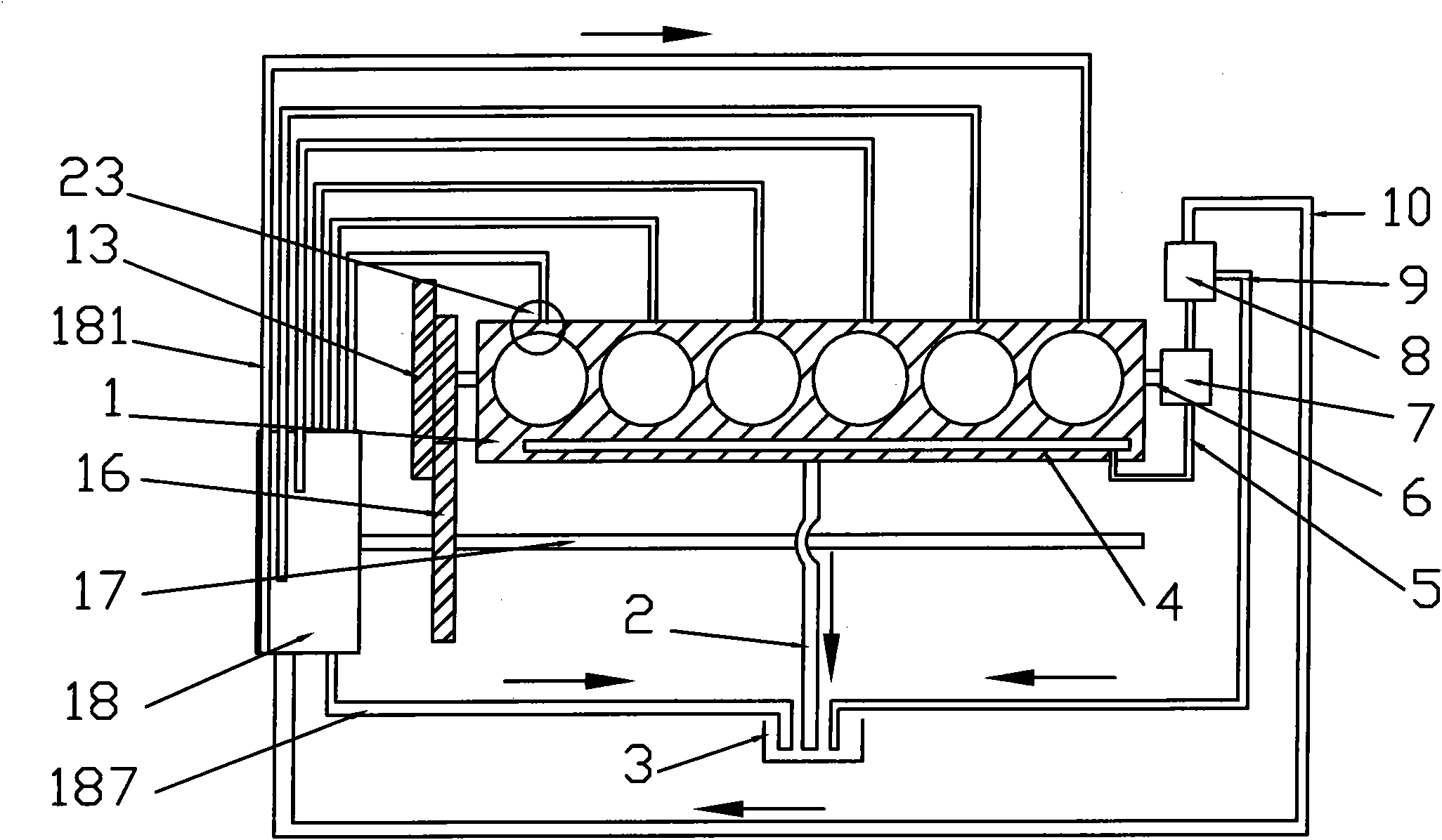

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] The purpose of the diesel engine hydraulic self-adaptive valve timing variable system of the present invention is to realize the variable valve timing on the side bottom camshaft diesel engine, mainly by adding a set of self-adaptive push rod length changing mechanism on the original engine push rod , according to the actual needs of the engine, the length of the push rod can be changed by means of the lower push rod in the mechanism, thus forming a combined intake valve push rod.

[0045] The movement of the hydraulic plunger in the adaptive push rod length changing mechanism is realized by pushing the hydraulic plunger (piston) to move up and down through the pressure oil entering and flowing out of the pressure chamber of the adaptive push rod length changing mechanism. The process of hydraulic oil flowing in and out is auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com