Molded motor

A motor and molding technology, applied in the field of motors, can solve the problems of high price, mold complexity, cost rise, etc., and achieve the effect of reliable maintenance, good handling and easy fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

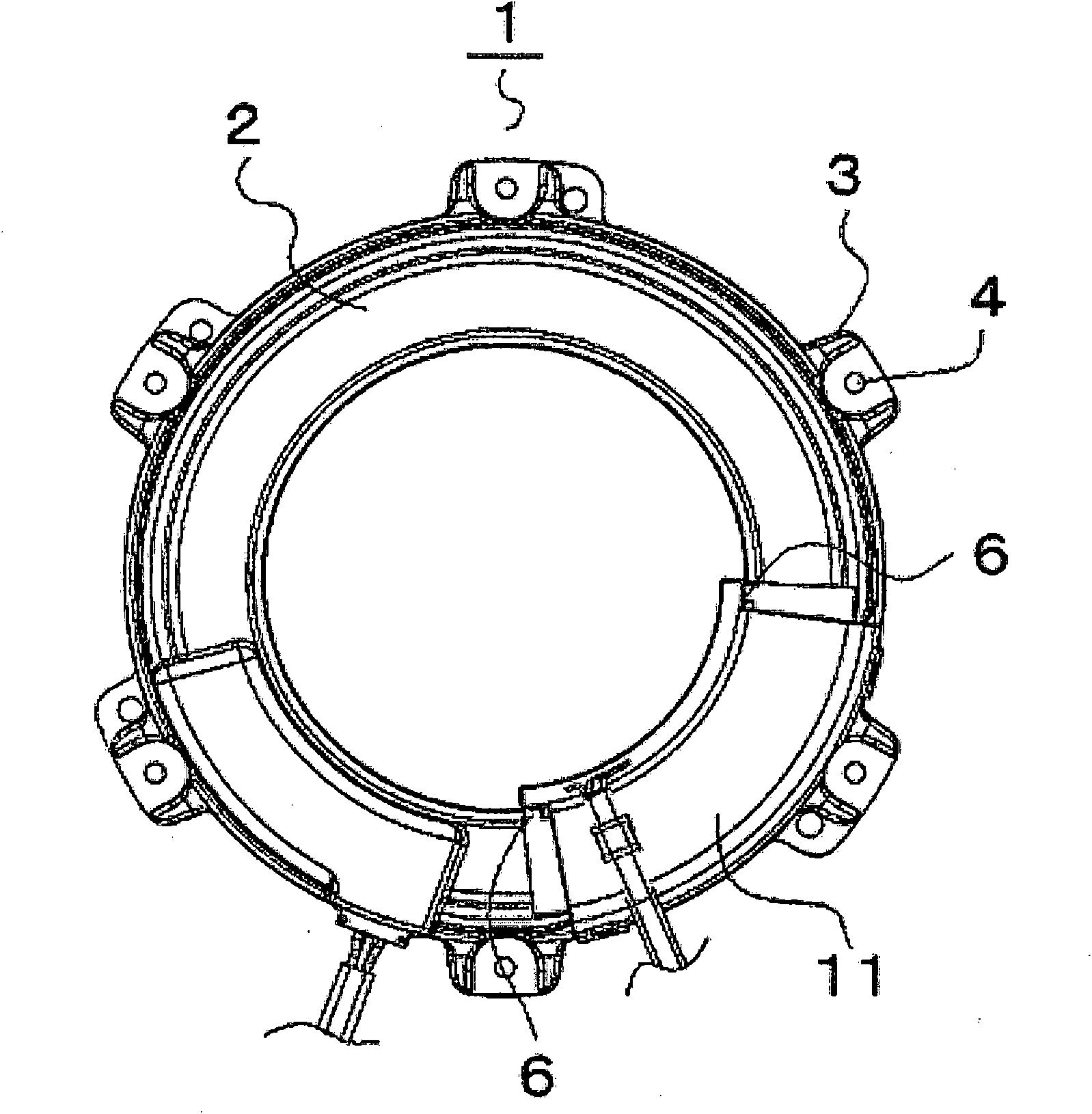

Embodiment 1

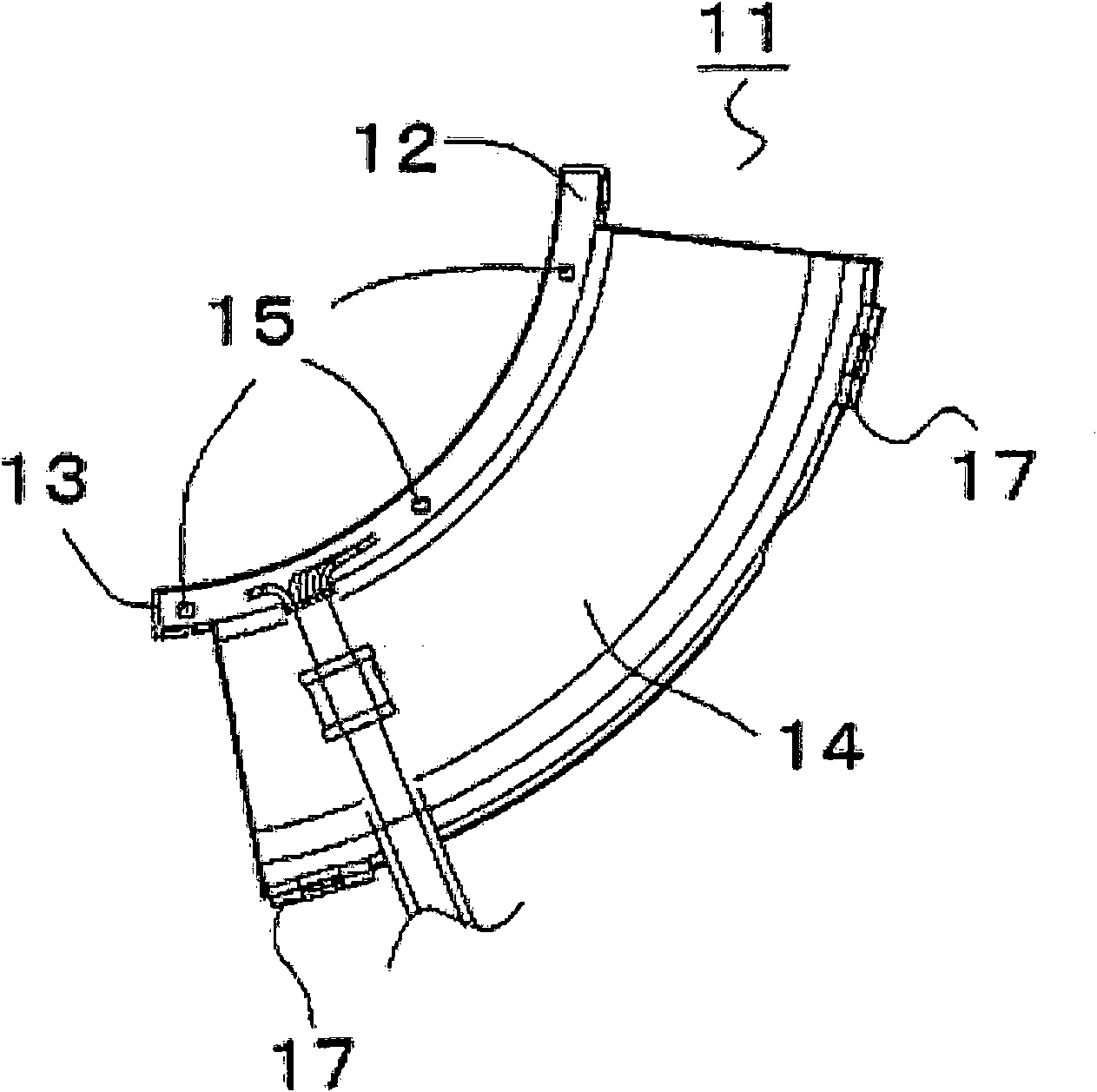

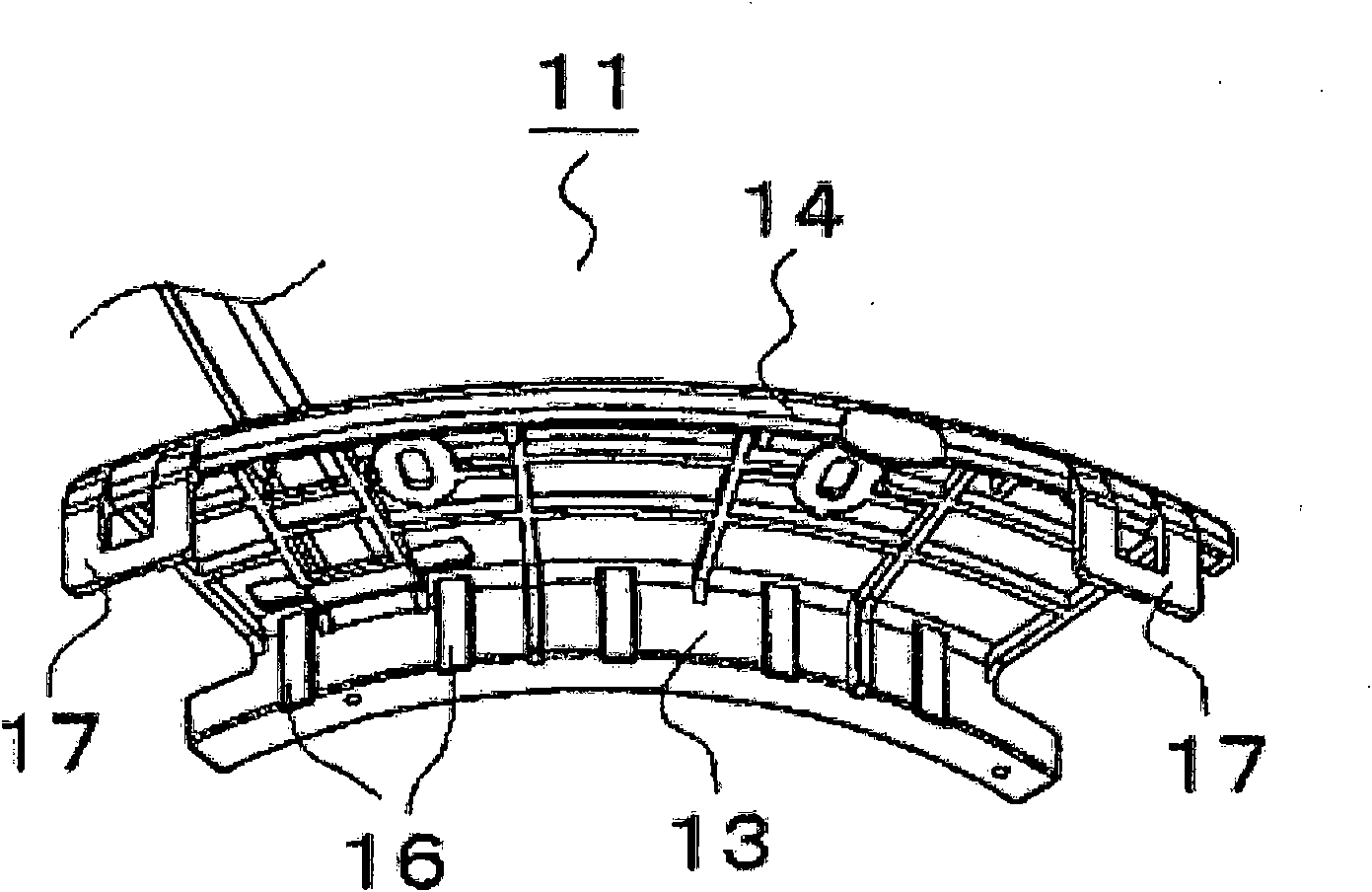

[0065] (shape of sensor holder)

[0066] according to figure 2 The sensor holder 11 includes an accommodating portion 13 for accommodating the wiring board 12 and a main body portion 14 for mounting on the stator 1 , and is formed in an arc shape corresponding to the shape of the stator 1 . The storage portion 13 is disposed on the inner peripheral side of the main body portion 14 , and the circumferential length of the storage portion 13 is formed longer than the circumferential length of the main body portion 14 .

[0067] The position sensor 15 is disposed in the storage portion 13 , and the wiring board 12 corresponding to the shape of the storage portion 13 is housed therein. The stored wiring board 12 is fixed by screwing, and the wiring board 12 and the position sensor 15 are protected by covering the interior of the housing portion 13 with a potting resin.

[0068] according to image 3 , the outer peripheral surface of the housing portion 13 is in contact with the...

Embodiment 2

[0078] Such as Image 6 As shown, a temperature protection element 21 is installed on the sensor bracket 11, and the temperature protection element 21 is used to detect the temperature of the stator 1 and protect the stator 1 from abnormal temperature. In addition, an element housing portion 22 is formed to hold the temperature protection element 21 .

[0079] The element housing portion 22 opens to the main body portion 14 of the sensor holder 11 , and a guide portion 23 is formed in the opening portion. The elastic force is obtained by forming the thickness of the guide portion 23 to be about 1 mm, thereby obtaining the holding force of the temperature protection element 21 . Furthermore, the bottom of the guide portion 23 is open, and heat from the stator can be reliably detected. Also, a plurality of protrusions 24 are formed on the side wall of the guide portion 23 so as to press the upper side of the temperature protection element 21 .

[0080] In addition, a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com