Silicone-self-adhesives, method for the production thereof, complexes using same and uses

A silicone, silicone oil technology, used in adhesives, transportation and packaging, thin material handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

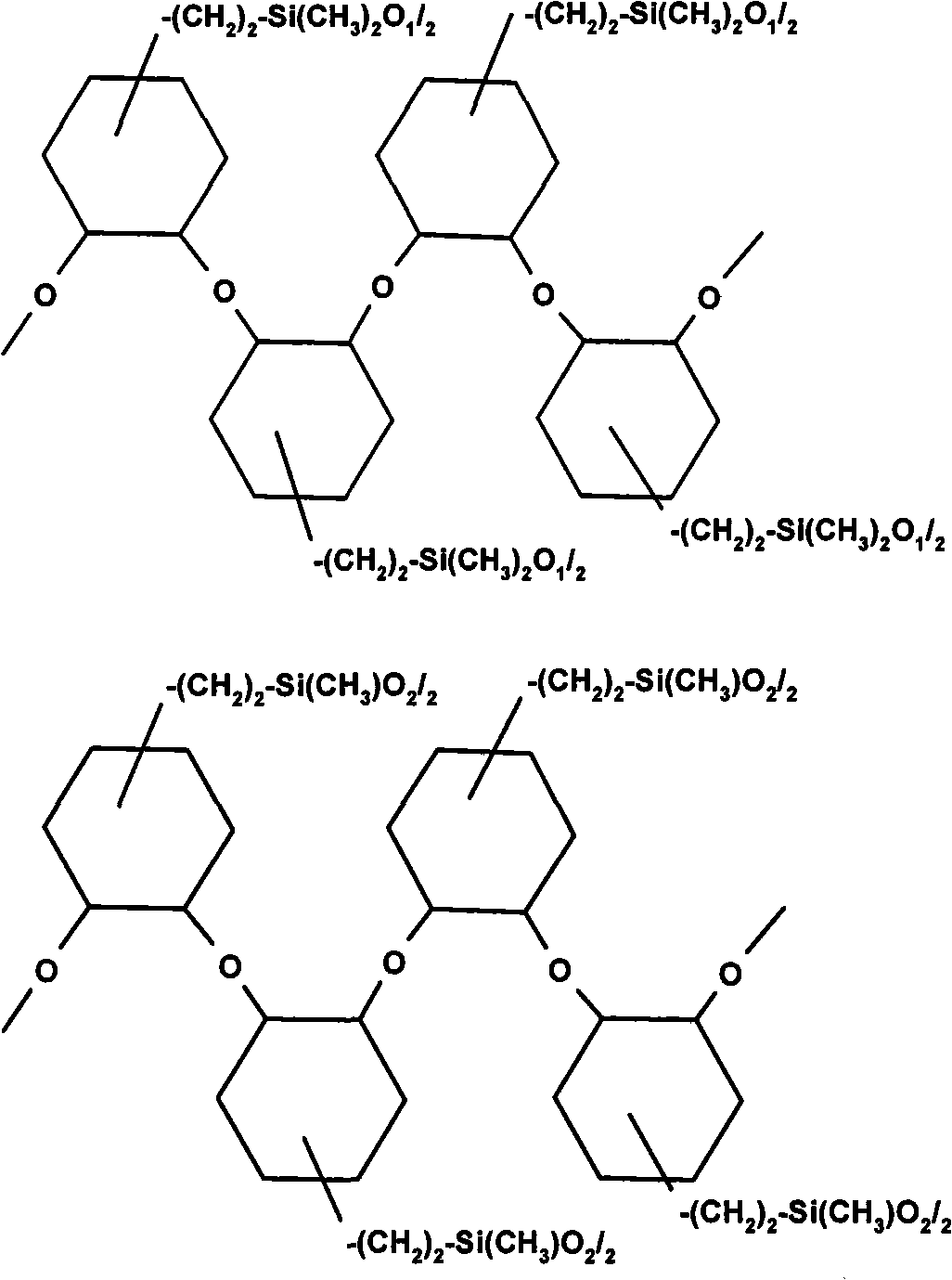

Method used

Image

Examples

Embodiment 1

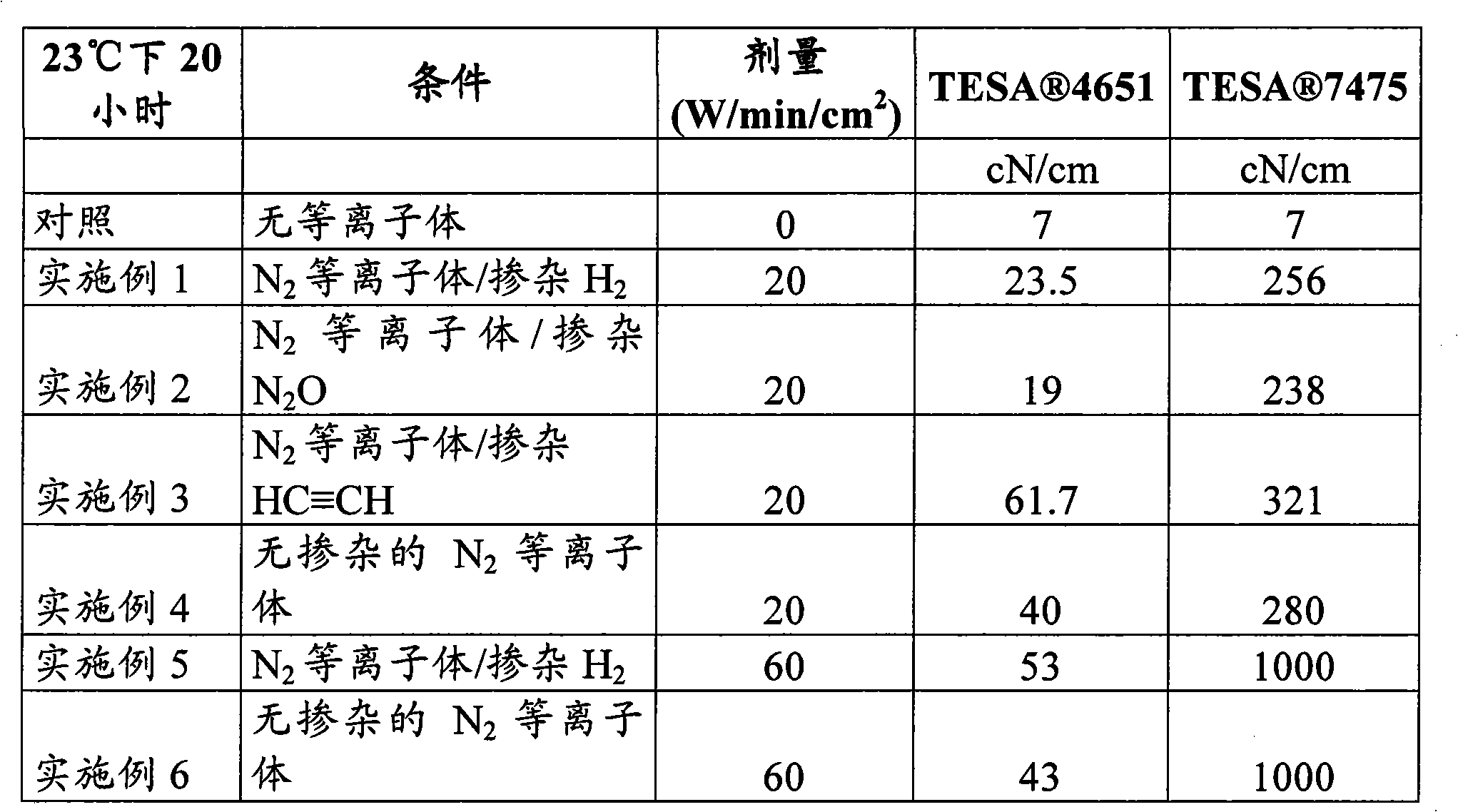

[0114] according to method, the electric dose on the silicone surface is 20W / min / cm 2 The crosslinked siliconized polyester film of Preparation 1 was treated with plasma at 75 m / min. The operation is carried out at normal temperature and pressure.

[0115] The method consists of the use of a filamentary discharge, which is homogeneously distributed in a gas mixture of controlled composition at atmospheric pressure, and the exclusion of any traces of oxygen in this air, by replacing e.g. Corona and / or primary coating Stations dry coat in automatic or queued mode.

[0116] Since the process gas used is pure nitrogen doped with 500 ppm hydrogen, the gas is reducing.

[0117] Use natural rubber adhesive 4651 and acrylic adhesive 7475 for queue coating.

Embodiment 2

[0119] according to method, the electric dose on the silicone surface is 20W / min / cm 2 The siliconized polyester film of Preparation 1 was treated with plasma at 75 m / min.

[0120] Since the process gas used is pure nitrogen doped with 500 ppm nitric oxide, the gas is oxidizing.

[0121] Use natural rubber adhesive 4651 and acrylic adhesive 7475 for queue coating.

Embodiment 3

[0123] according to method, the electric dose on the silicone surface is 20W / min / cm 2 The siliconized polyester film of Preparation 1 was treated with plasma at 75 m / min.

[0124] Since the process gas used was pure nitrogen doped with 500 ppm acetylene, the gas was organic.

[0125] Use natural rubber adhesive 4651 and acrylic adhesive 7475 for queue coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com