Tapered part punching method and combined process dimension control device

A stamping process and cone-shaped technology, which is applied in the field of stamping process methods for cone-shaped parts and combined process size control devices, can solve the problems of difficult on-site management, low equipment utilization rate, and long production cycle, so as to improve equipment utilization. The effect of high efficiency, shortened production cycle, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

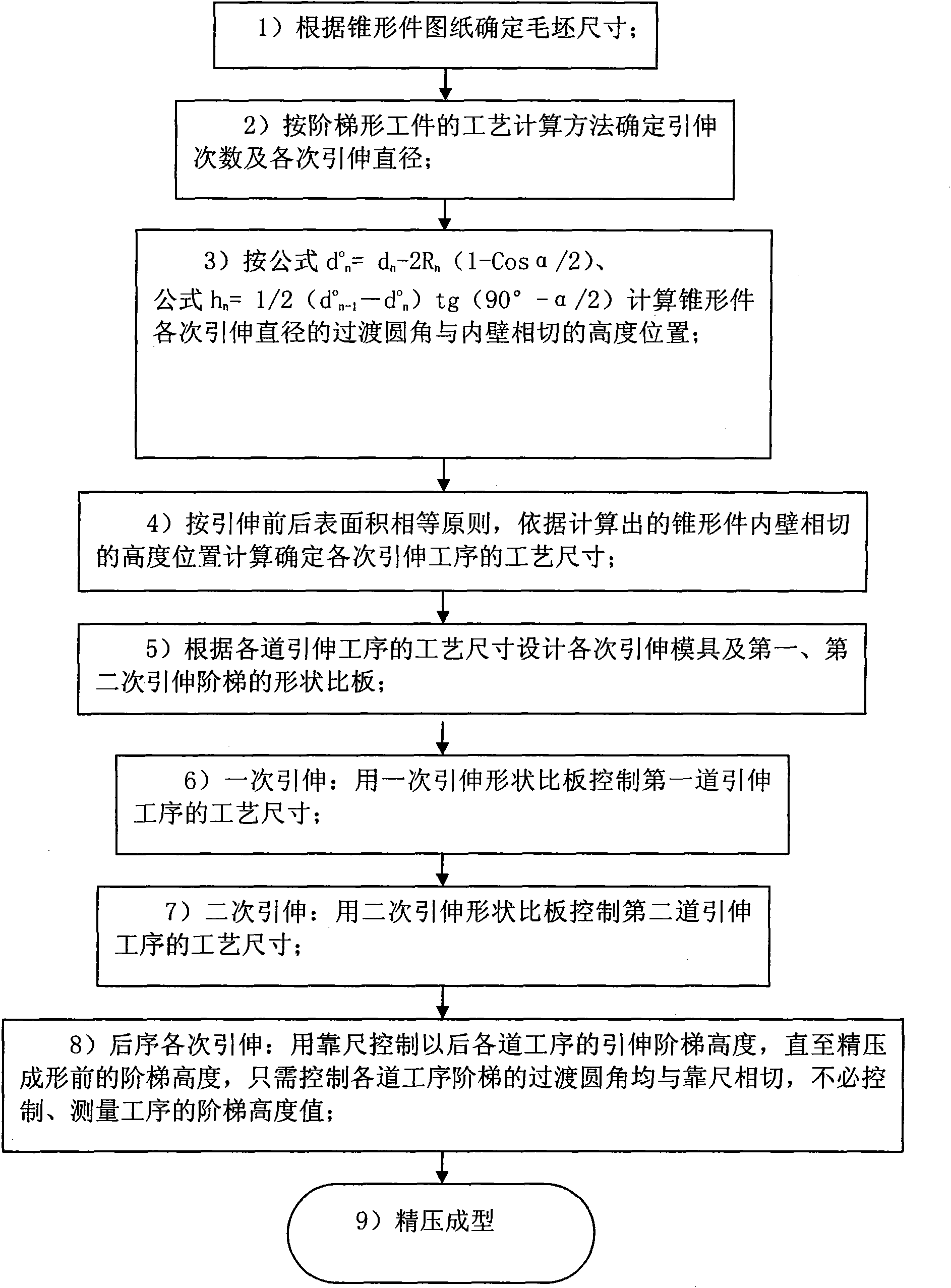

[0045] refer to figure 1 , a stamping method for a tapered part, it comprises the following steps:

[0046] 1) Determine the size of the blank according to the drawing of the tapered part;

[0047] 2) Determine the number of extensions and the diameter of each extension according to the process calculation method of the ladder-shaped workpiece;

[0048] 3) According to the formula d° n = d n -2R n (1-Cosα / 2), formula h n =1 / 2(d° n-1 -d° n )tg(90°-α / 2) Calculate the height position where the transition fillet of each extension diameter of the conical part is tangent to the inner wall;

[0049] Where: d° n - the diameter of the tangent point between the transition fillet of the nth extension diameter and the inner wall of the tapered part,

[0050] d n - the diameter of the nth extension,

[0051] d° n-1 - the diameter of the tangent point be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com