Auxiliary propulsion system of underwater vehicle

An underwater vehicle and auxiliary propulsion technology, which is applied in the directions of ship propulsion, propulsion components, non-mechanical gear transmission, etc., can solve the problem of inflexible structure, etc., and achieve the effect of high efficiency, flexibility and low vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

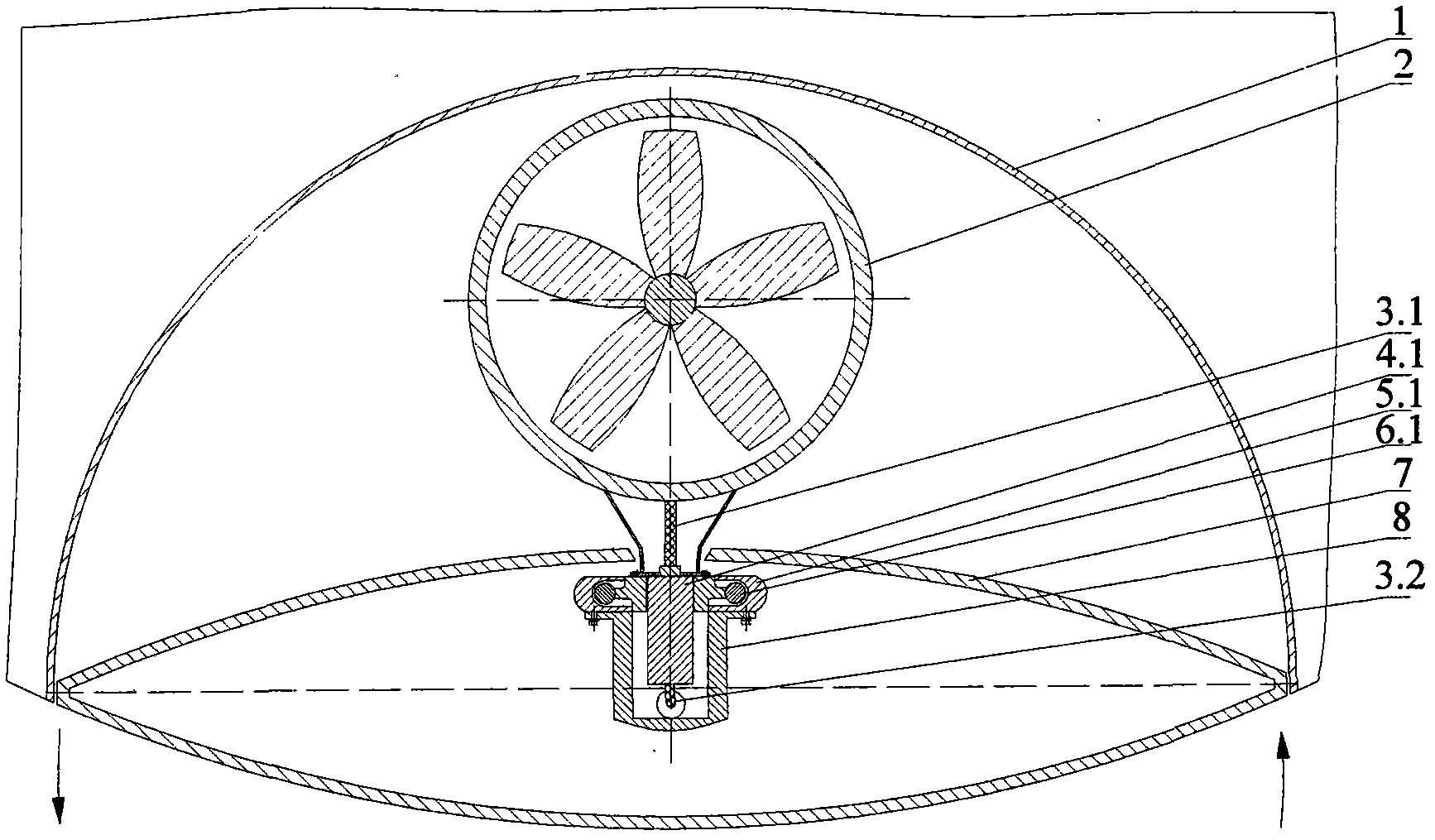

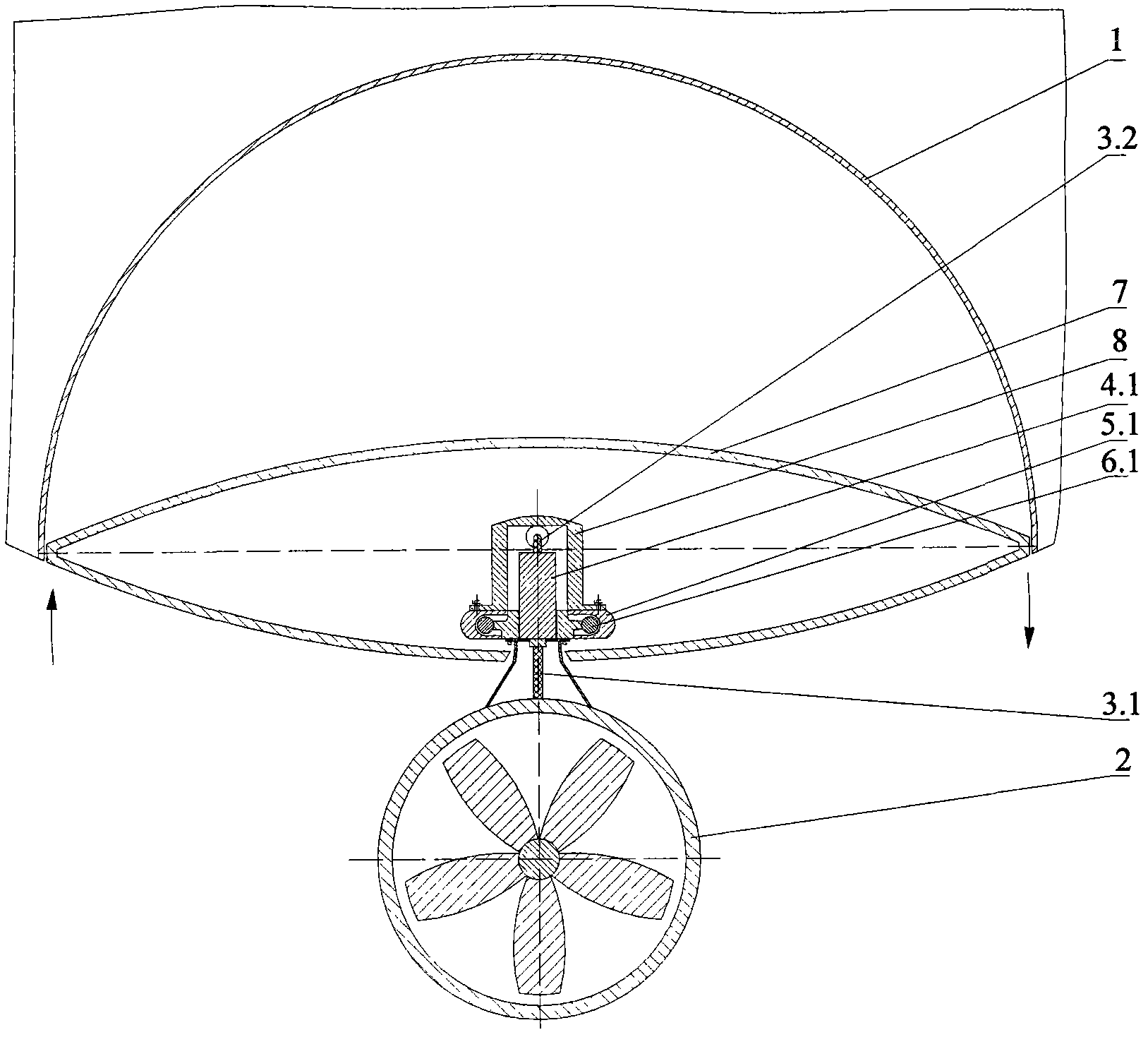

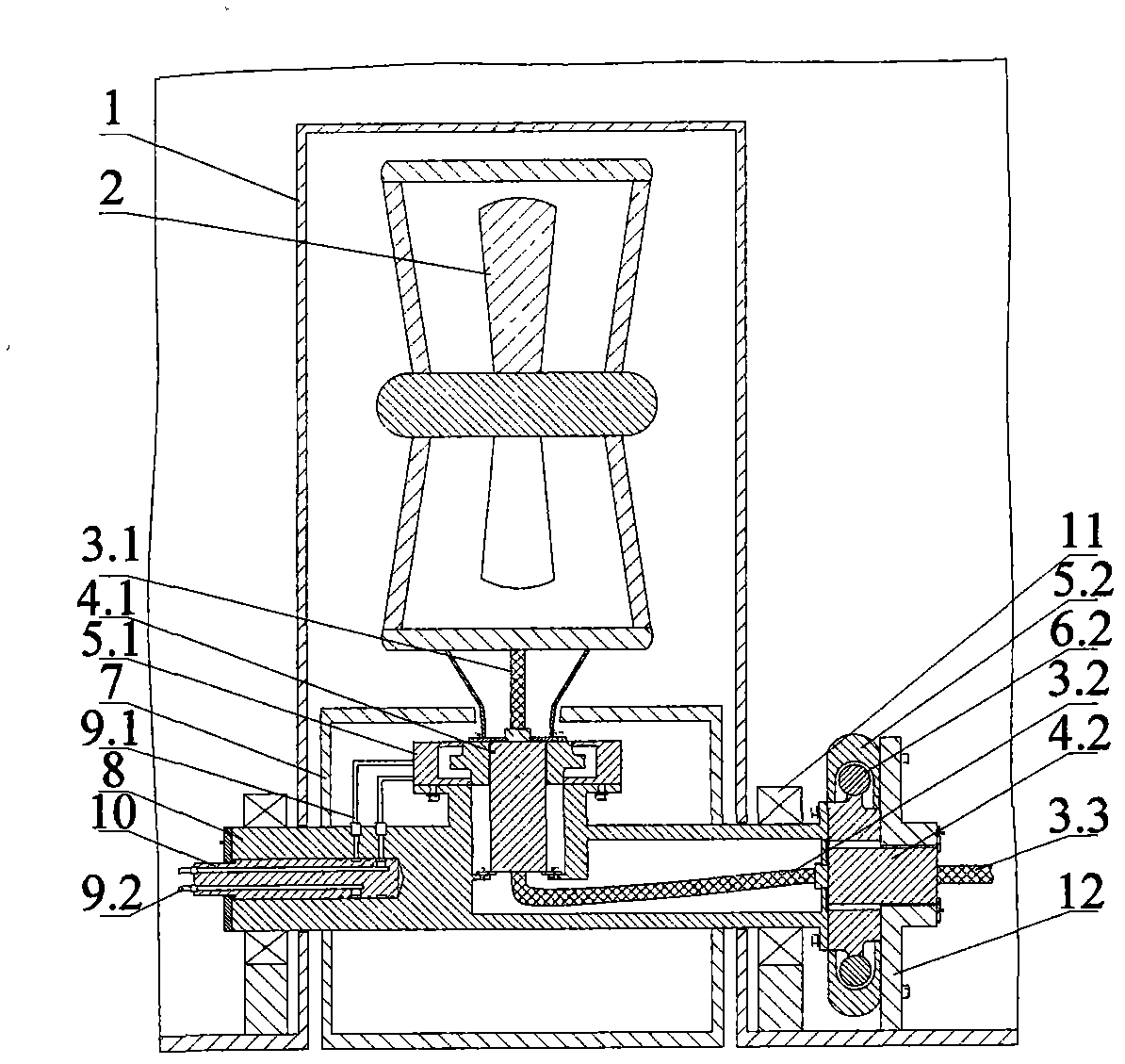

[0018] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0019] It includes a shell 1 with an opening at the bottom connected to the underwater vehicle. The shell is in the shape of a semi-disc. The hollow shaft 8 that runs through the front and back is installed in the middle of the lower part of the shell. The seat 11 is supported, and one end of the hollow rotating shaft is connected with the rotary retractable device. The rotary retractable device is composed of a reducer 5.2 and a hydraulic motor 6.2 installed on the seat frame 12; The horizontal conductive slip ring 4.2 configured with the device and the inner and outer cables 3.2, 3.3 are arranged. The stator of the horizontal conductive slip ring is fixed on the frame, and its rotor rotates with the hollow shaft; the middle part of the hollow shaft is provided with a base , the base is provided with a rotation mechanism, the base is connected with the integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com