Disc brake for belt conveyor

A technology of disc brakes and belt conveyors, applied in conveyors, underground transportation, transportation and packaging, etc., can solve problems such as short service life of brakes, jamming phenomenon, easy loosening of nuts, etc., to ensure sealing performance and use Life, avoid jamming phenomenon, ensure the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

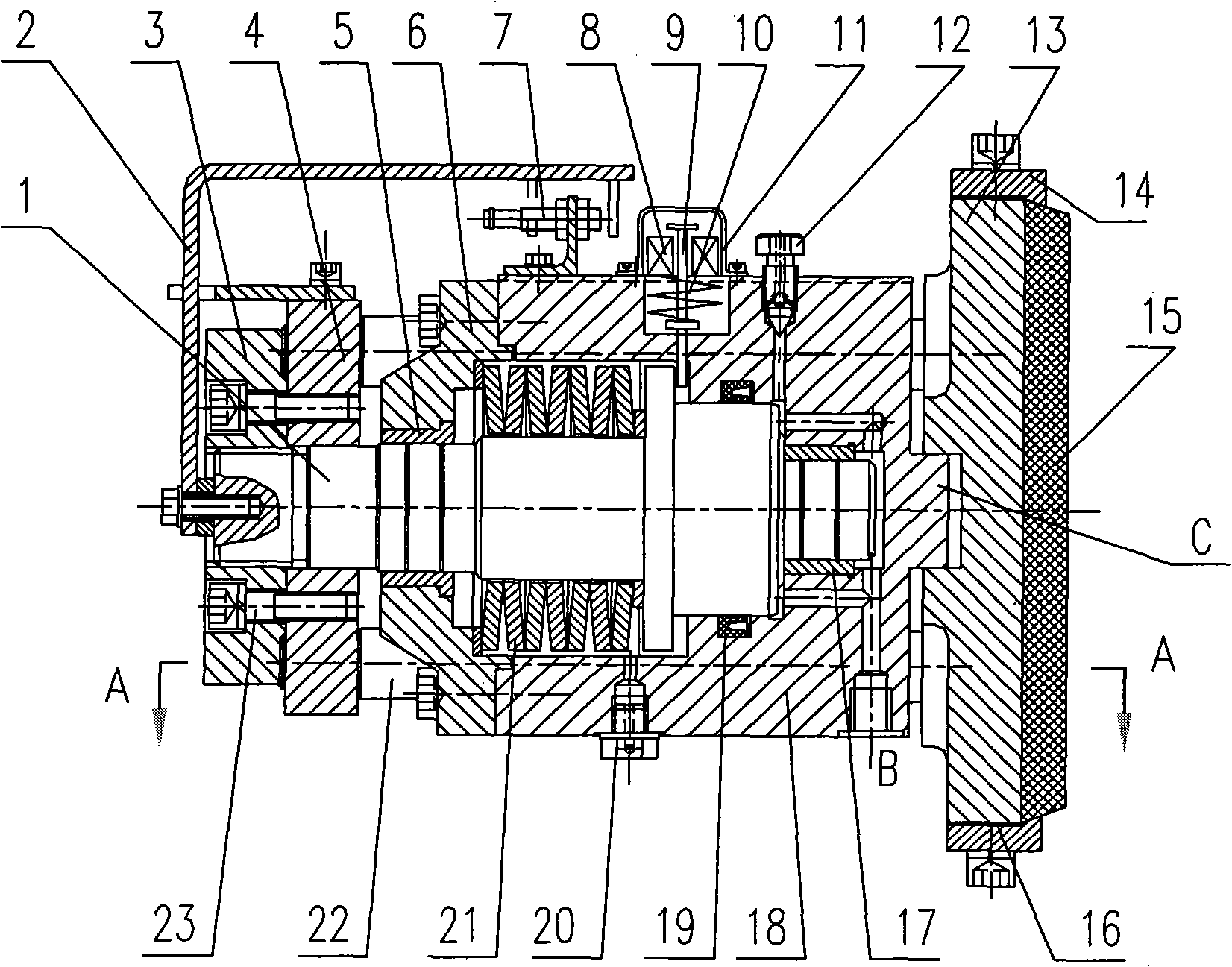

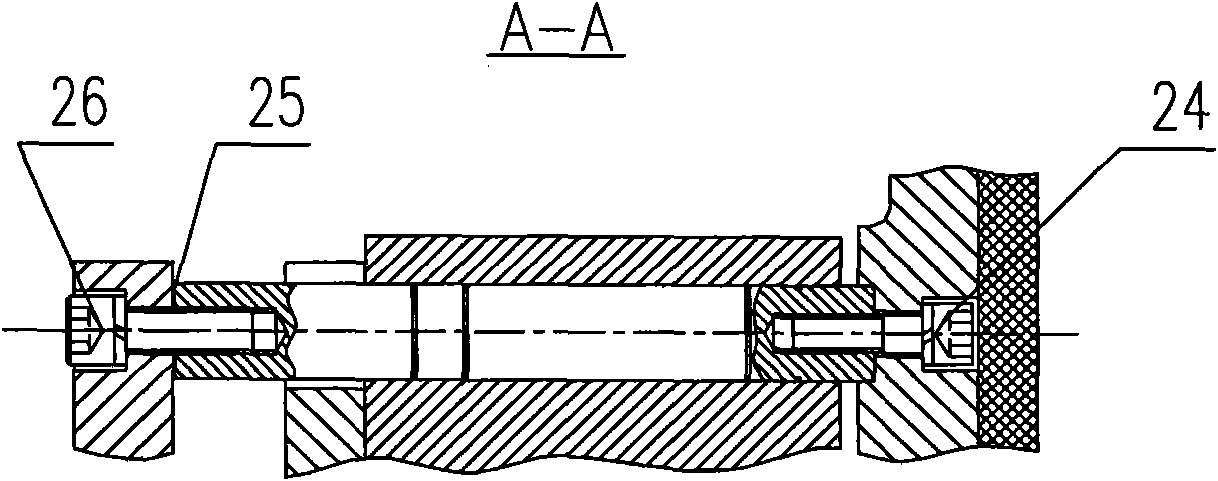

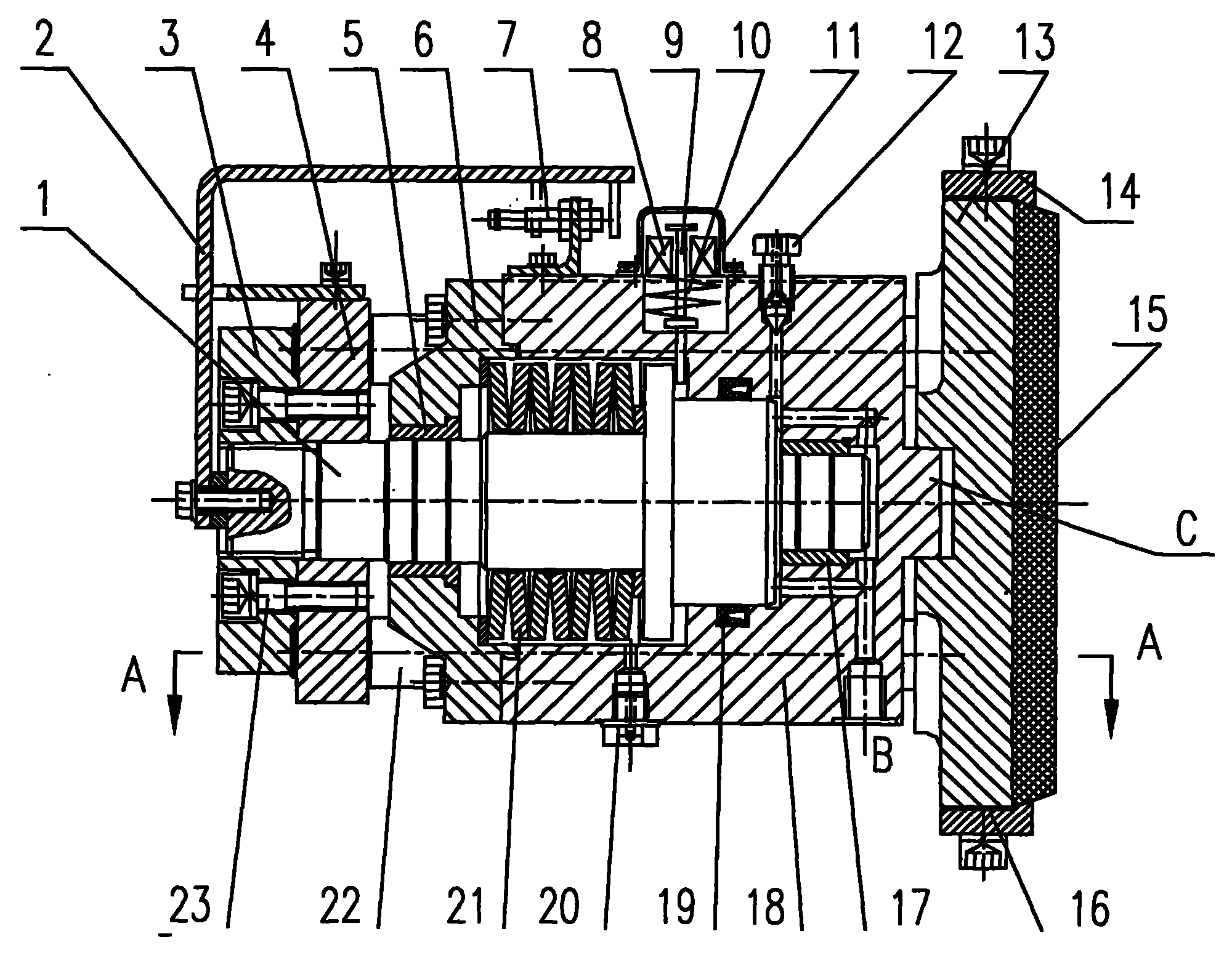

[0010] An example of the present invention will be further described below in conjunction with accompanying drawing:

[0011] figure 1 As shown, the belt conveyor disc brake of the present invention is mainly composed of a piston 1, a displacement indicator plate 2, an adjustment nut 3, a thrust plate 4, a cover plate 6, a displacement sensor 7, a brake shoe support seat 13, a brake seat 18, Brake shoe 15, disc spring 21, cover plate 6, support column 22 and the protective device of abnormal braking are formed. Among them: the butterfly spring 21 is set on the piston 1 and installed in the brake seat 18 together. The brake shoe 15 is connected with a brake shoe support seat 13 with a groove in the middle. The upper and lower parts of the brake shoe 15 and the brake shoe support seat 13 are provided with The brake shoe pressing plate 14 which is fixed together, the brake shoe 15 is fixed on the brake shoe support seat 13 through the brake shoe pressing plate 14, and the matchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com