Novel crystallization method for recycling thermal-sensitive dissolving solution-containing medium

A technology with temperature sensitivity and a new method, applied in the direction of ferric sulfate, etc., can solve problems such as single crystallization method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

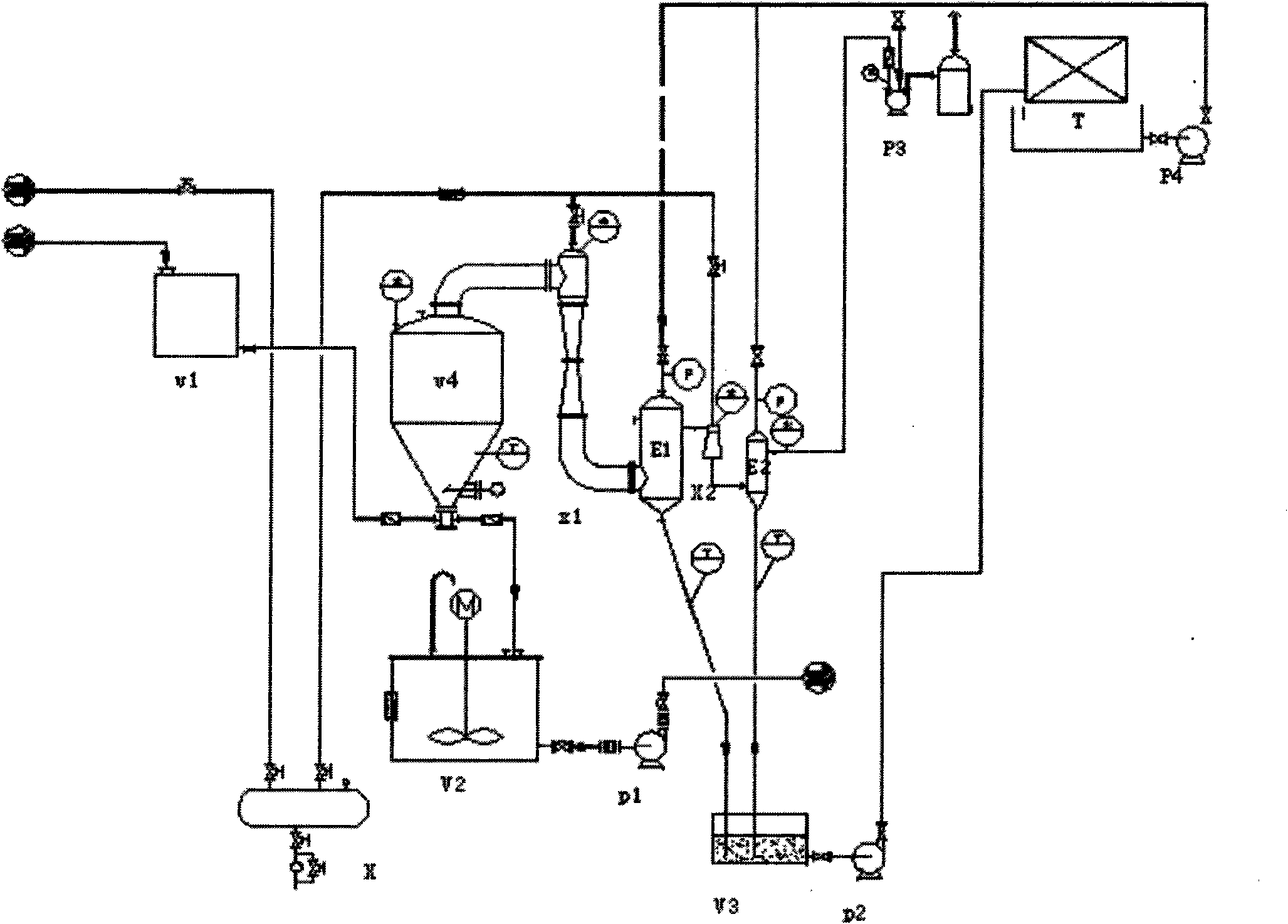

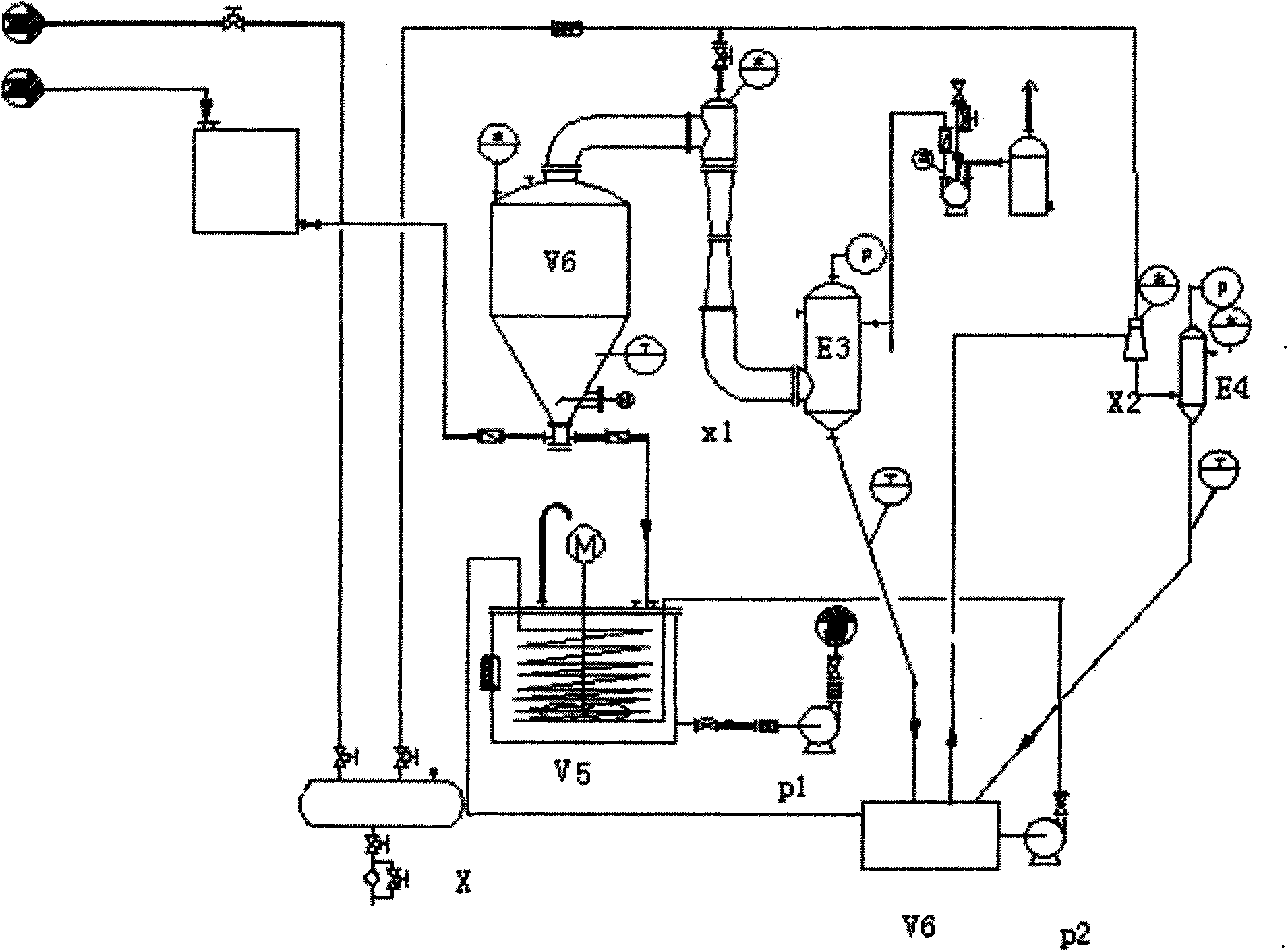

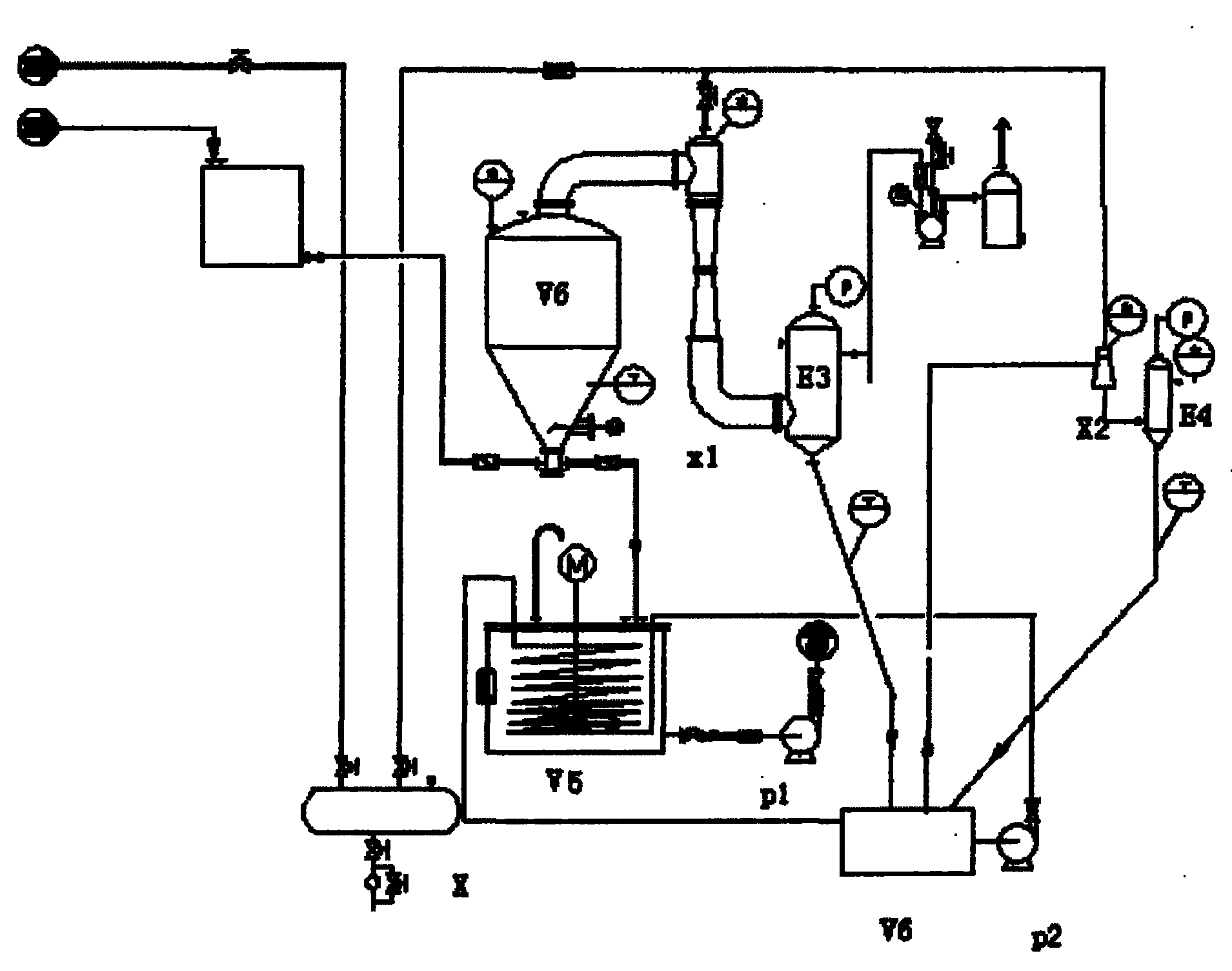

Image

Examples

Embodiment 1

[0028] The titanium liquid at 53 degrees Celsius and 125g / l iron-titanium ratio of 0.78 flowing out of the high-level tank continuously enters the vacuum crystallizer, and the vacuum degree of the vacuum crystallizer gradually increases under the action of 0.35MPa superheated steam passing through the main and auxiliary jet injectors. Increase to 0.09-0.098MPa; the temperature of the titanium liquid flows from top to bottom in the vacuum crystallizer, and the ferrous sulfate gradually becomes saturated. After 30 minutes, the temperature of the titanium liquid gradually decreases to 33 degrees Celsius, and 25% of the ferrous sulfate crystallizes Precipitation, the suspension containing ferrous sulfate crystals flows into the freezing crystallization tank, and the concentration of the titanium solution is increased to 155g / l; in the freezing crystallization tank, it exchanges heat indirectly with the cold liquid at 7 degrees Celsius from the lithium bromide refrigerator for 150 mi...

Embodiment 2

[0032] The titanium liquid at 52 degrees Celsius and 124g / l copper-titanium ratio of 0.77 flowing out of the high-level tank continuously enters the vacuum crystallizer, and the vacuum degree of the vacuum crystallizer gradually increases under the action of the 0.36MPa superheated steam passing through the main and auxiliary spray injectors. Increase to 0.09-0.098MPa; the temperature of the titanium liquid flows from top to bottom in the vacuum crystallizer, and the cuprous sulfate gradually becomes saturated. After 32 minutes, the temperature of the titanium liquid gradually decreases to 32 degrees Celsius, and 26% of the cuprous sulfate crystallizes Precipitation, the suspension containing cuprous sulfate crystals flows into the freezing crystallization tank, and the concentration of the titanium solution is increased to 157g / l; in the freezing crystallization tank, it exchanges heat indirectly with the cold liquid at 7 degrees Celsius from the lithium bromide refrigerator fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com