Treatment method of glass metal in platinum channel

A platinum channel and processing method technology, applied in glass furnace equipment, glass manufacturing equipment, feeding troughs, etc., can solve problems such as increased glass defects, poor clarification, and refractory erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

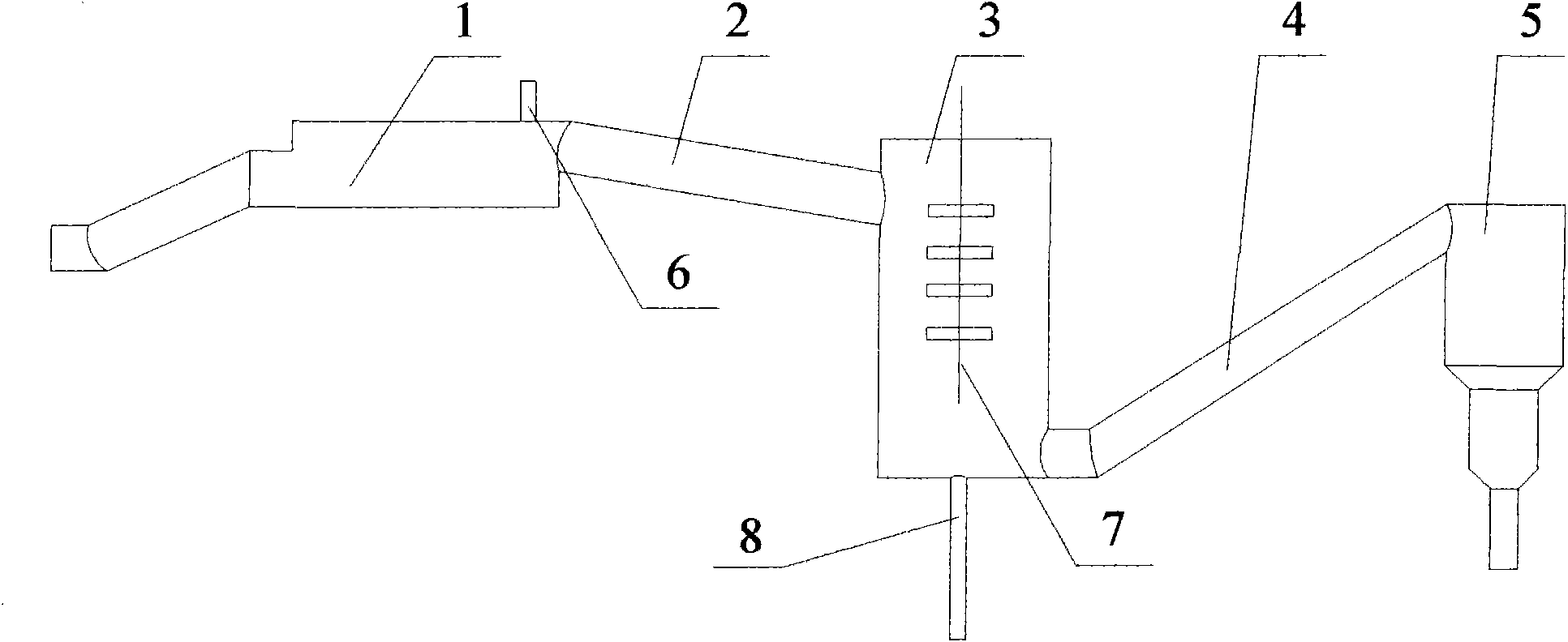

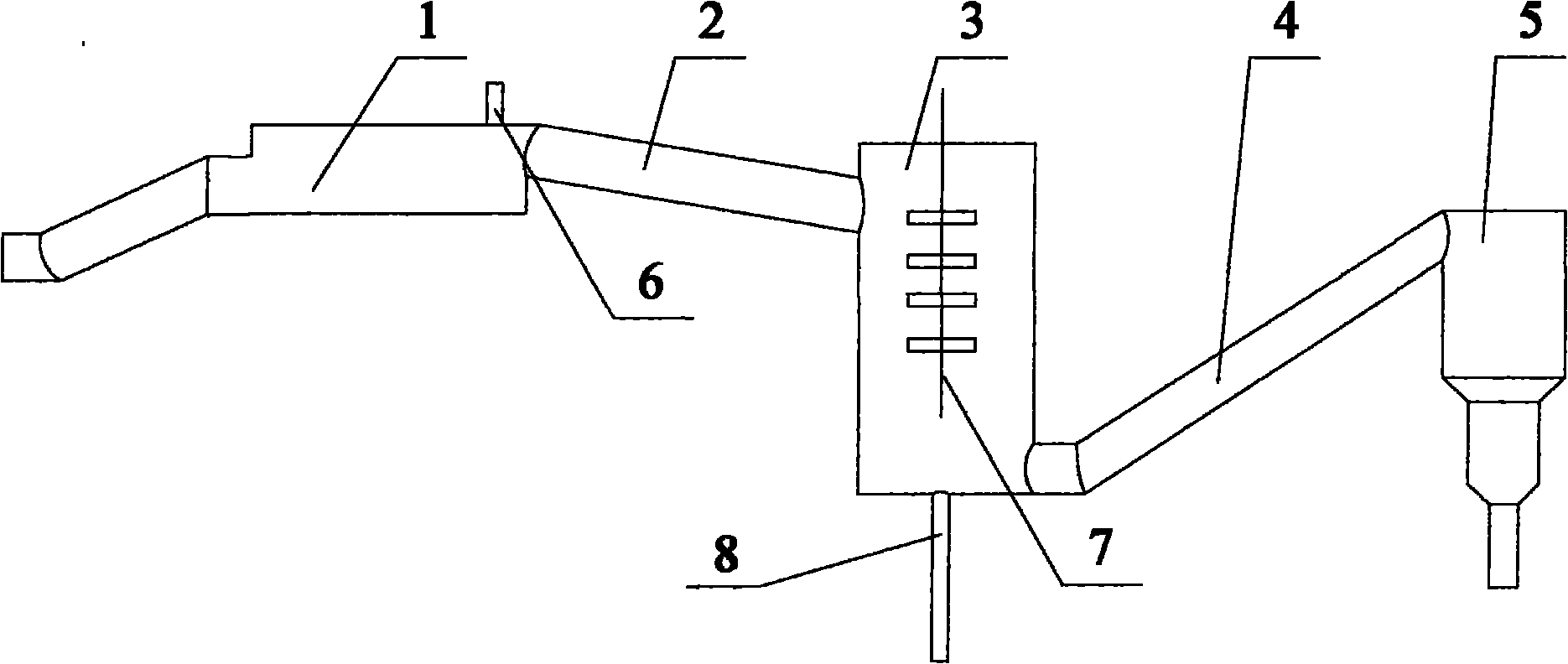

[0016] see figure 1 , the treatment method of molten glass in the platinum channel, the molten glass is clarified and homogenized in the inner cavity of the platinum channel by means of an electric heating flange, and the inner cavity of the platinum channel is divided into clarification chamber 1, cooling chamber 2, and stirring chamber 3 , homogenizing bin 4, and feeding bin 5, carry out the following steps respectively:

[0017] ①. The length of the clarification chamber 1 is set to 2000-5000mm, the depth of the glass liquid is controlled at 100-240mm, and the top of the end of the clarification chamber 1 is provided with an exhaust pipe 6; the cross-sectional area of the clarification chamber 1 is 200cm 2 to 1600cm 2 Platinum pipes can be round pipes, elliptical pipes or rounded square pipes. The external insulation material of platinum pipes is mainly composed of thermal insulation materials with good heat insulation performance and high temperature resistance, so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com